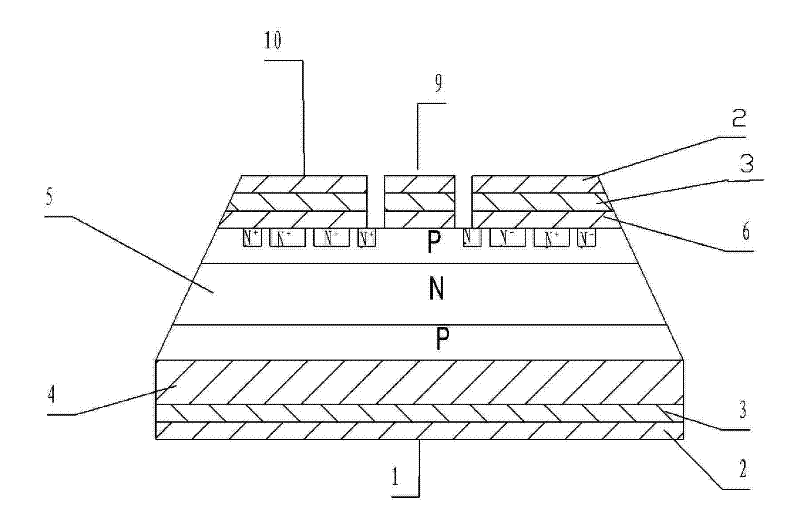

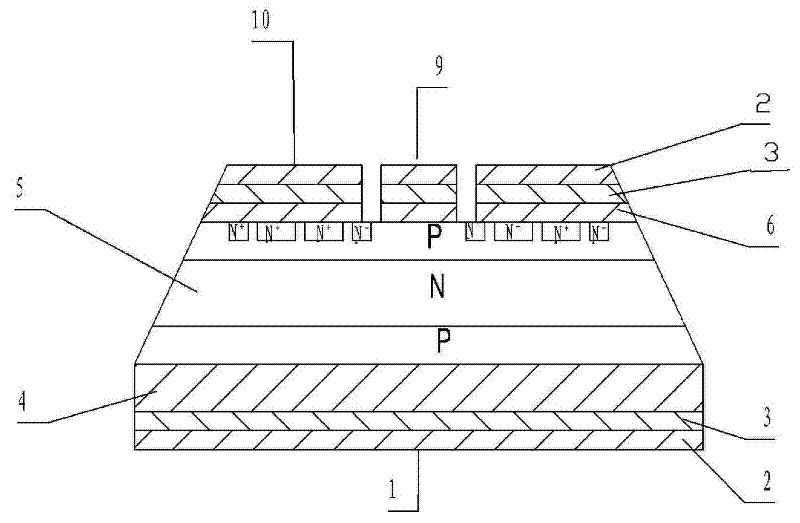

Thyristor core manufacturing process

A manufacturing process and thyristor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low die withstand voltage level, poor die mechanical properties, low reliability, etc., to ensure dynamic characteristics, Simplified die manufacturing process, easy removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The specific manufacturing process and steps of the present invention are as follows, wherein boron diffusion, oxidation, primary photolithography, phosphorous diffusion, secondary photolithography, surface corrosion, and angle grinding are all conventional thyristor tube core manufacturing methods.

[0027] 1. Boron diffusion: adopt the conventional coating diffusion method, use ultra-pure diboron trioxide and pure aluminum nitrate to configure the impurity source, apply the impurity source on the surface of the prepared single crystal silicon wafer, and place it in a diffusion furnace at 1200°C. Constant temperature for 25h, diffusion in the atmosphere, so that borosilicate glass body is formed on the surface of the silicon wafer, forming a P-N-P structure (that is, forming j1 junction and j2 junction), and then polishing;

[0028] 2. Oxidation: Clean the surface of the boron-diffused silicon wafer with a cleaning solution, dehydrate it for use, and then put the cleane...

Embodiment 2

[0041] Concrete manufacturing process and steps of the present invention are as follows:

[0042] 1. Boron diffusion: adopt the conventional coating diffusion method, use ultra-pure diboron trioxide and pure aluminum nitrate to configure the impurity source, apply the impurity source on the surface of the prepared single crystal silicon wafer, and place it in a diffusion furnace at 1400°C. Constant temperature for 40h, diffusion in the atmosphere, so that borosilicate glass body is formed on the surface of the silicon wafer, forming a P-N-P structure (that is, forming j1 junction and j2 junction), and then polishing;

[0043] 2. Oxidation: Clean the surface of the boron-diffused silicon wafer with a cleaning solution, dehydrate it for use, and then put the cleaned and dehydrated silicon wafer into a diffusion furnace for oxidation treatment, in which dry oxygen for 60 minutes, Wet oxygen for 150 minutes, dry oxygen for 60 minutes, wet oxygen for 130 minutes, dry oxygen for 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com