Multi-layer ceramic electronic parts and method for mfg. same

A technology of multilayer ceramics and electronic components, which is applied in fixed capacitance components, laminated capacitors, ceramic layered products, etc., and can solve problems such as damage to electrical characteristics, damage to soldering performance, electroplating Sn, and failure to fix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

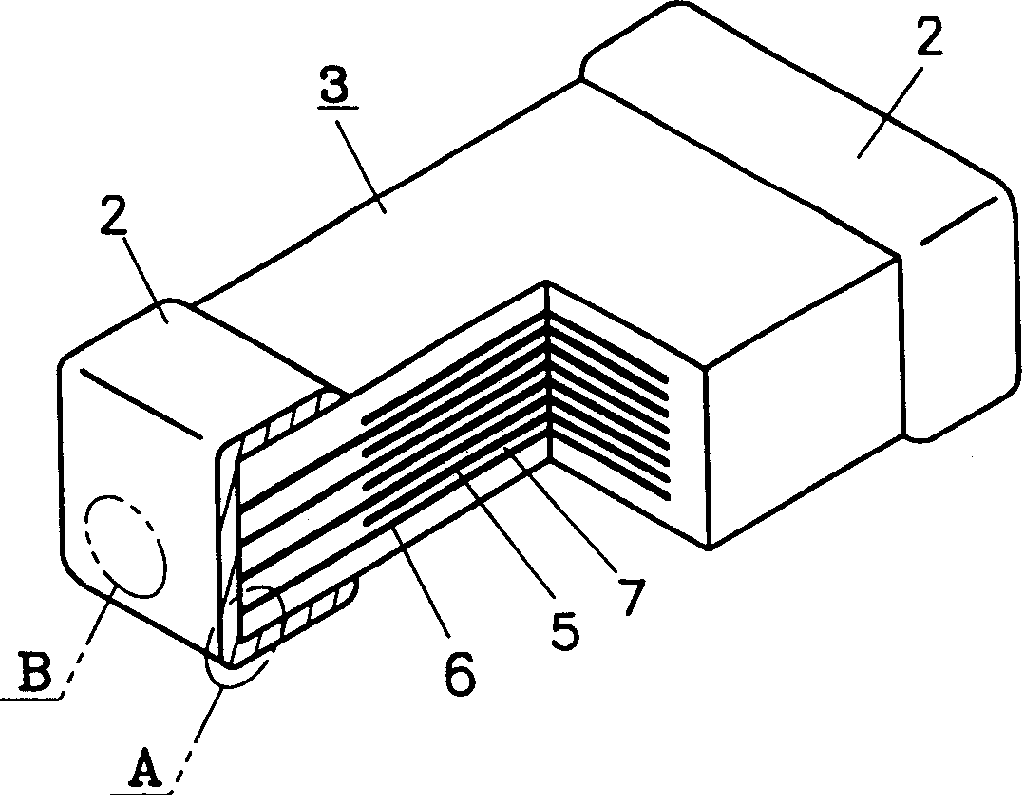

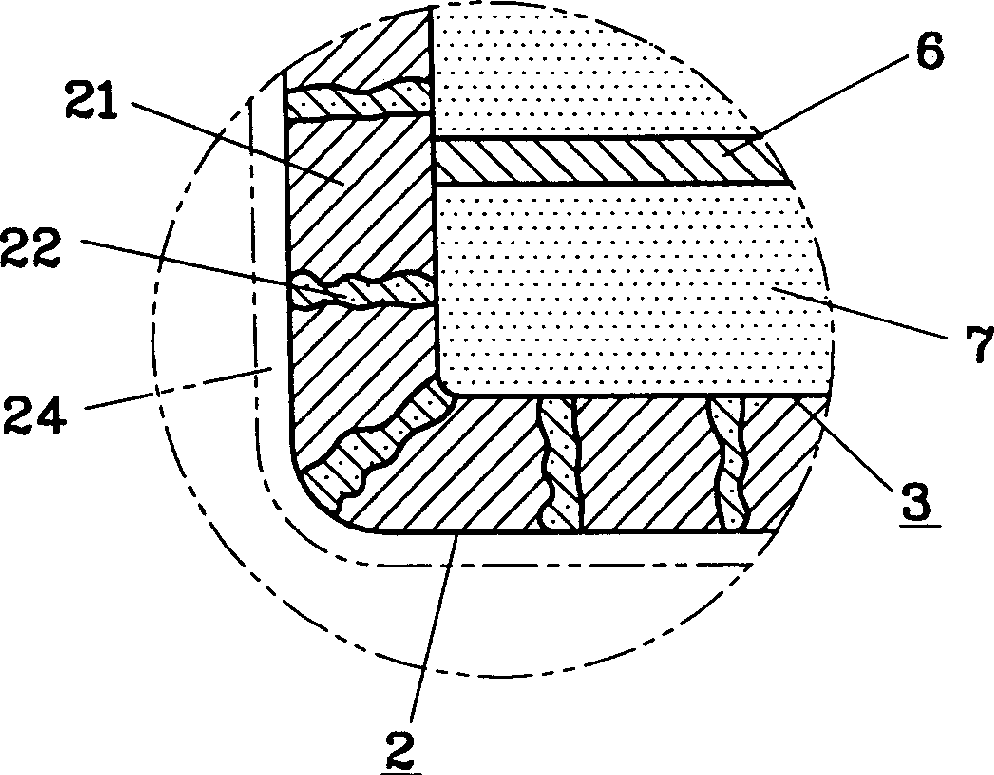

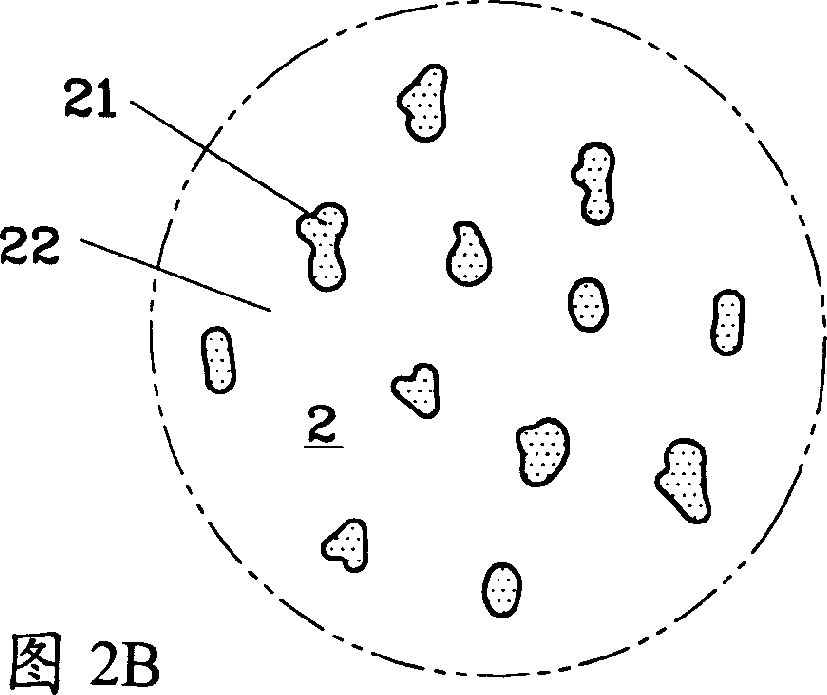

[0047] An example of a multilayer ceramic electronic component - a multilayer ceramic capacitor and its manufacturing method - is introduced here.

[0048] First, dielectric ceramic material particles such as barium titanate are dispersed in an organic binder (such as acryl, etc., acryl) that can be dissolved in a solvent such as ethanol, thereby preparing a ceramic slurry. The ceramic slurry is glued or thinly applied to a base film formed of polyethylene terephthalate or the like at a uniform thickness, and dried to form a film-type ceramic green sheet. Thereafter, the green sheet is cut to the appropriate size.

[0049] Next, if Figure 4 As shown, two kinds of internal electrodes 2a and 2b are printed on the cut ceramic green sheets 1a and 1b with a conductive paste. The conductive paste is obtained like this: add 100% by weight of a conductor particle selected from Ni, Cu, Ag, Pd, Ag-Pd, 3-12% by weight from ethylcellulose (ethylcellulose), propylene A binder selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com