Manufacturing method for planar bidirectional trigger diode chip

A bidirectional triggering and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as complex procedures, high cost, and unacceptable market, and achieve the effect of reducing fragmentation rate and high rebound voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

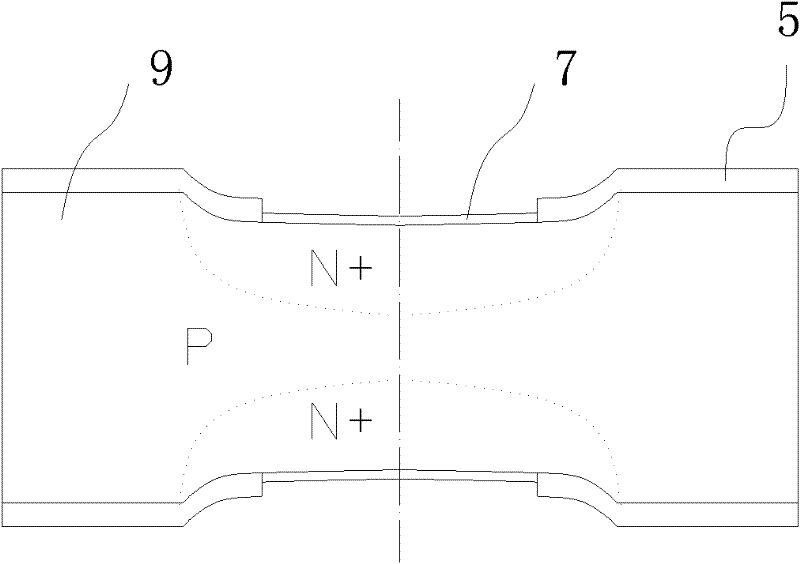

[0028] The present invention as Figure 1-11 Shown: using a P-type wafer 1 with a thickness of 100-300 μm as a raw material, the process of growing an oxide layer 2 on the surface of the wafer 1, a photolithographic diffusion window 3 and cutting the wafer 1 into chips 9, in the process of the photolithographic diffusion window 3 and The process of cutting the wafer 1 into chips 9 includes the following processes:

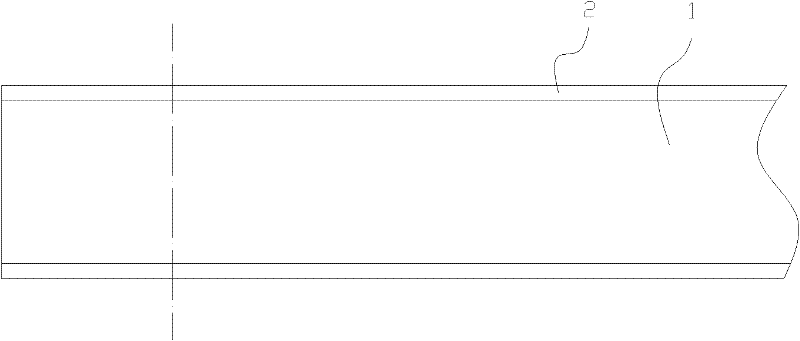

[0029] The aforementioned process of growing an oxide layer is as follows: figure 2 Shown: the cleaned P-type wafer 1 is grown at 1050°C with an oxide layer 2 as a diffusion mask;

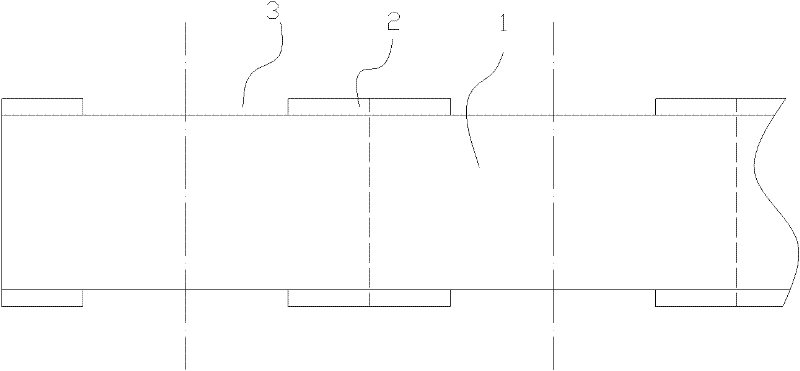

[0030] The process of forming diffusion window by photolithography is as follows: image 3 As shown, a part of the oxide layer 2 is removed on the surface of the wafer 1 by a photolithography process to leave a diffusion window 3 .

[0031] 1) Diffusion window sinks; such as Figure 4 After cleaning, inject mixed acid into the diffusion window 3 to corrode the surface of the wafer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com