Photon microflow detection chip based on LTCC integration

A detection chip and detector chip technology, applied in the field of micro-system sensing, can solve the problems of difficult control of micro-channel size, high cost, complex manufacturing technology, etc., achieve good anti-corrosion characteristics, reduce manufacturing cycle, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

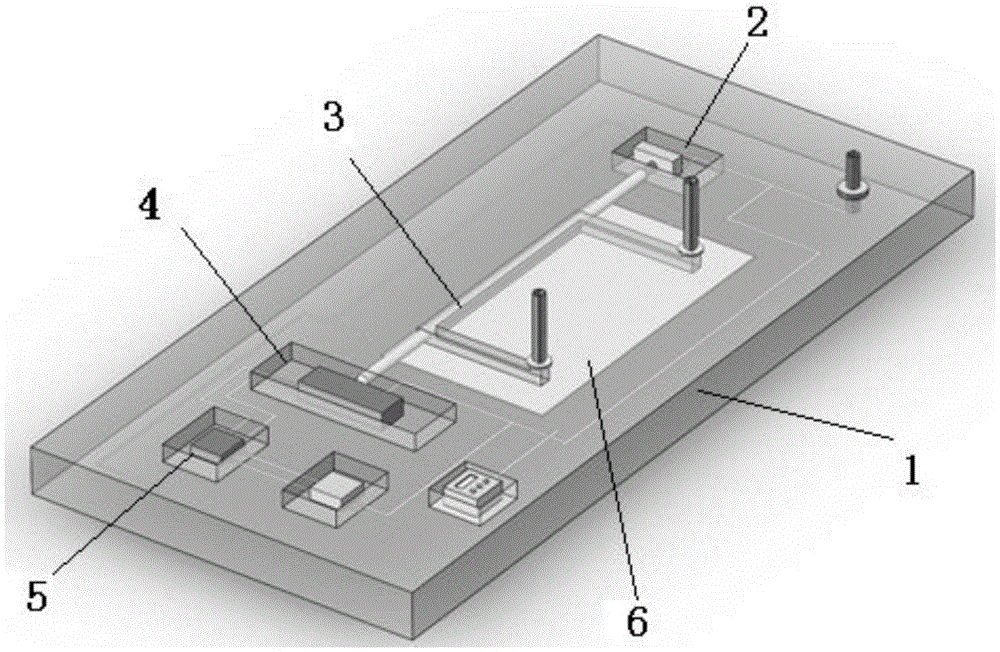

[0032] In the present invention, the LTCC substrate is made of Dupont951 ceramic sheet, and the thickness of each layer of the ceramic sheet is 114 μm. In this example, 20 layers of ceramic chips are used to construct the detection chip.

[0033] In the present invention, the optical fiber system uses the multimode bare optical fiber of Corning Corporation.

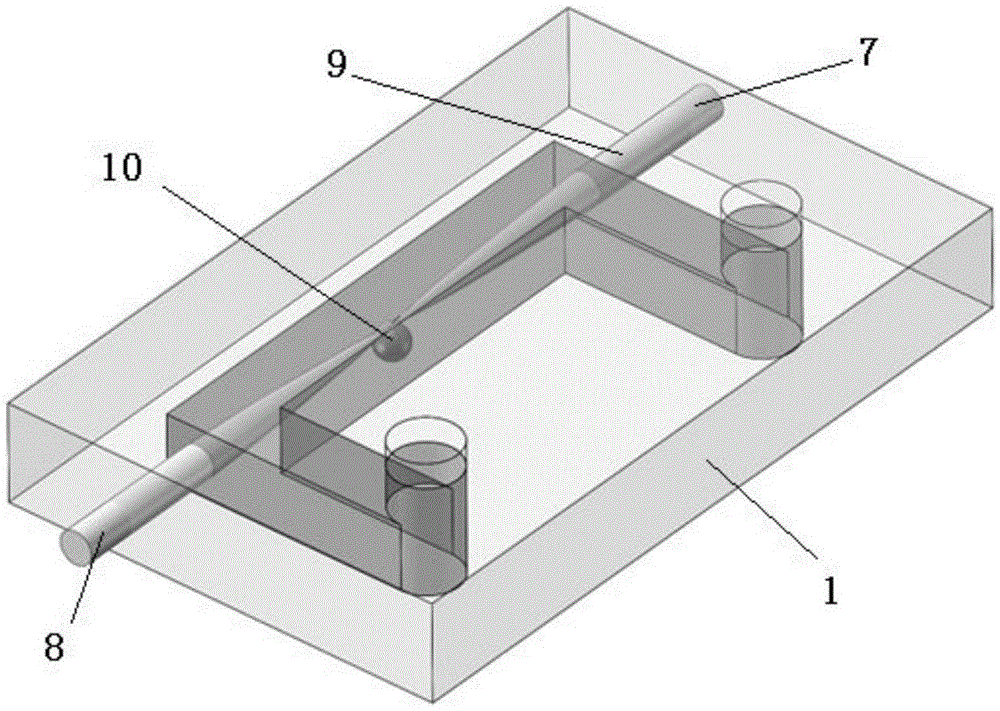

[0034] The schematic diagram of the photon sensing system in the microfluidic channel of the present invention is as follows: figure 2 shown. The cross-sectional size of the microfluidic channel is 1 mm × 1 mm. The photonic sensing system uses a high-Q optical microcavity sensing unit.

[0035] Based on the LTCC monolithic integrated photon microfluidic test method, the laser emitted by the light source chip is used as the signal source, and the photon detection source enters the photon sensing system in the microfluidic channel through the optical fiber system, and the detection of external substances is realized at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com