Coating and application thereof

A coating and coating technology, applied in asphalt coatings, epoxy resin coatings, coatings, etc., can solve problems such as carbon black and achieve good high-temperature performance

Inactive Publication Date: 2017-11-07

过春明

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the pipe coating of WO 00 / 55271 exhibits excellent high temperature performance, its use requires a premixing step and the presence of carbon black

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0057] The preparation process of the pipeline coating in the present invention is as follows: heating asphalt to 165° C., adding styrene-butadiene rubber, epoxy resin and glass flakes, and mixing uniformly to obtain the pipeline coating.

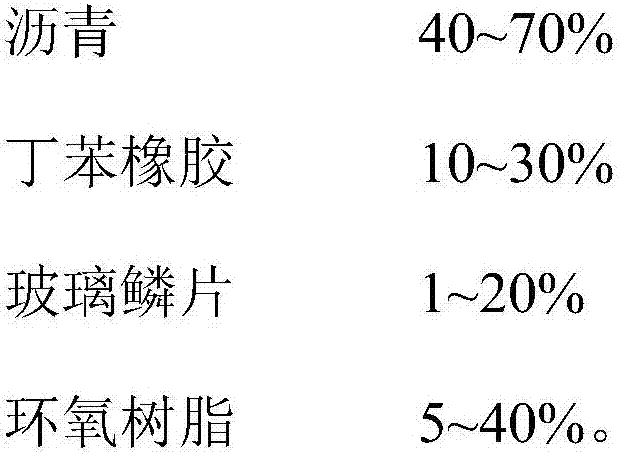

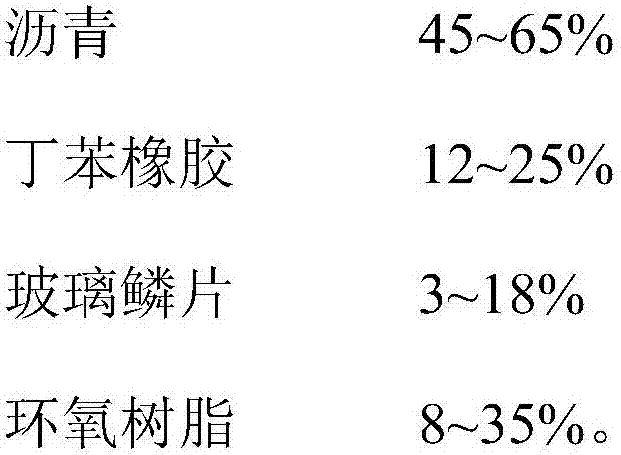

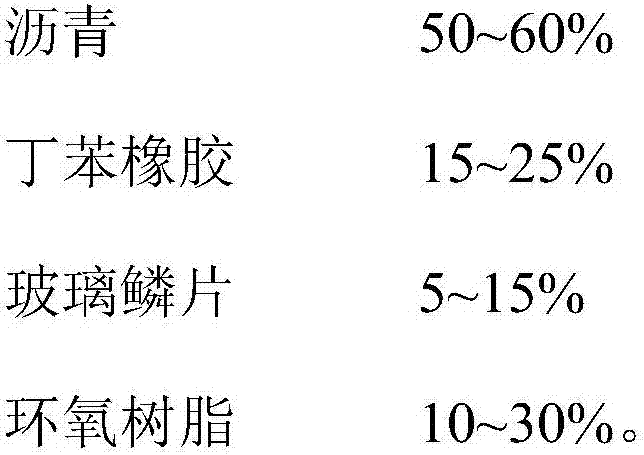

[0058] The composition by weight percentage of the pipeline coatings described in Examples 1-3 is shown in Table 1.

[0059] Table 1 Example 1-3 pipeline coating composition

[0060]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a pipeline coating containing an asphalt composition. The coating is prepared from the following components in percentage by weight: 40 to 70 percent of asphalt, 10 to 30 percent of styrene-butadiene rubber, 1 to 20 percent of glass flake and 5 to 40 percent of epoxy resin. The invention also provides a pipeline coated with the pipeline coating, a method for coating the pipeline by using the pipeline coating and a purpose of the asphalt composition as the pipeline coating. The production method of the pipeline coating provided by the invention is simple; the pipeline coating not only has excellent impact resistance and flexibility, but also shows excellent high-temperature characteristic and adhesive force.

Description

technical field [0001] The invention relates to pipeline coatings, in particular to a coating and its application, in particular to a method for coating pipelines and the use of asphalt compositions as pipeline coatings. Background technique [0002] Pipeline is an effective facility for long-distance or short-distance transportation of gas, liquid and slurry materials with minimal impact on the environment. Long and large diameter pipes are usually made of corrosion resistant carbon steel based materials, iron based materials. The corrosion process is a naturally occurring process in which iron is transformed into oxides by the action of water and oxygen from the air. This process affects almost all ferrous structures above, below ground and in water. Visible and above-ground structural members may be protected by application of ordinary paint or some other form of coating. However, lines are seldom visible, so they must be protected from the environment with a suitable ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D195/00C09D163/00C09D109/06C09D7/12B05D5/00B05D5/10B05D7/24

CPCC09D195/00B05D5/00B05D5/10B05D7/24B05D2518/00B05D2601/20B05D2602/00C08L2203/18C08L2205/03C09D163/00C08L63/00C08L9/06C08K7/00C08L95/00

Inventor 过春明

Owner 过春明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com