Pipeline elbow cutting device

A cutting device and a technology for pipe elbows, applied in the field of pipe fittings processing, can solve the problems of not being able to adapt to large-scale industrial production, problems that have not been solved well, taking up a lot of manpower and equipment, and achieve reliable quality of elbow cutting and forming. Improvement of cutting production efficiency and reduction of construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

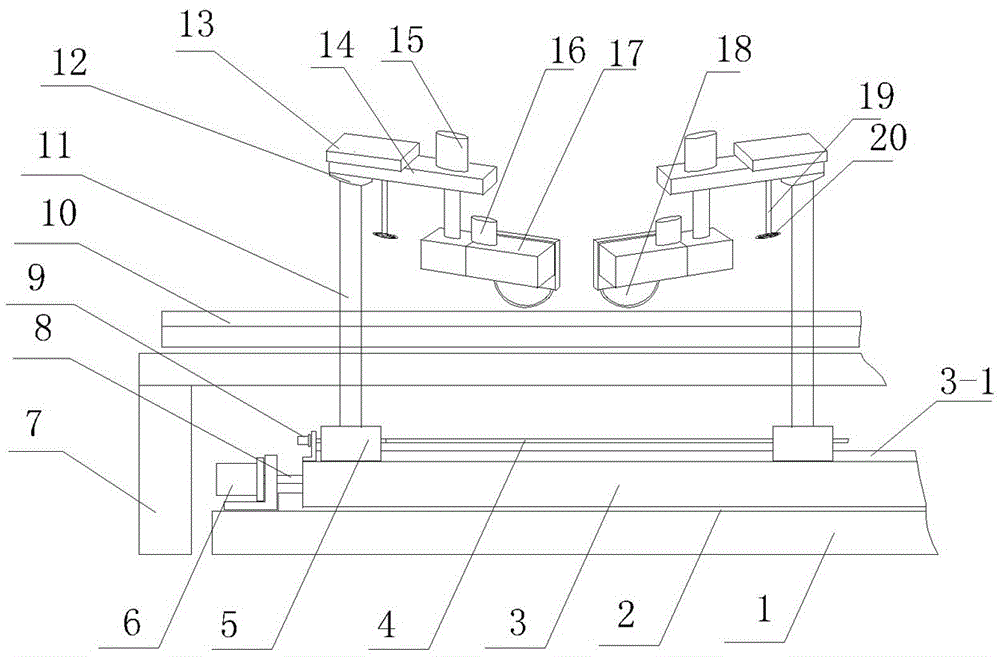

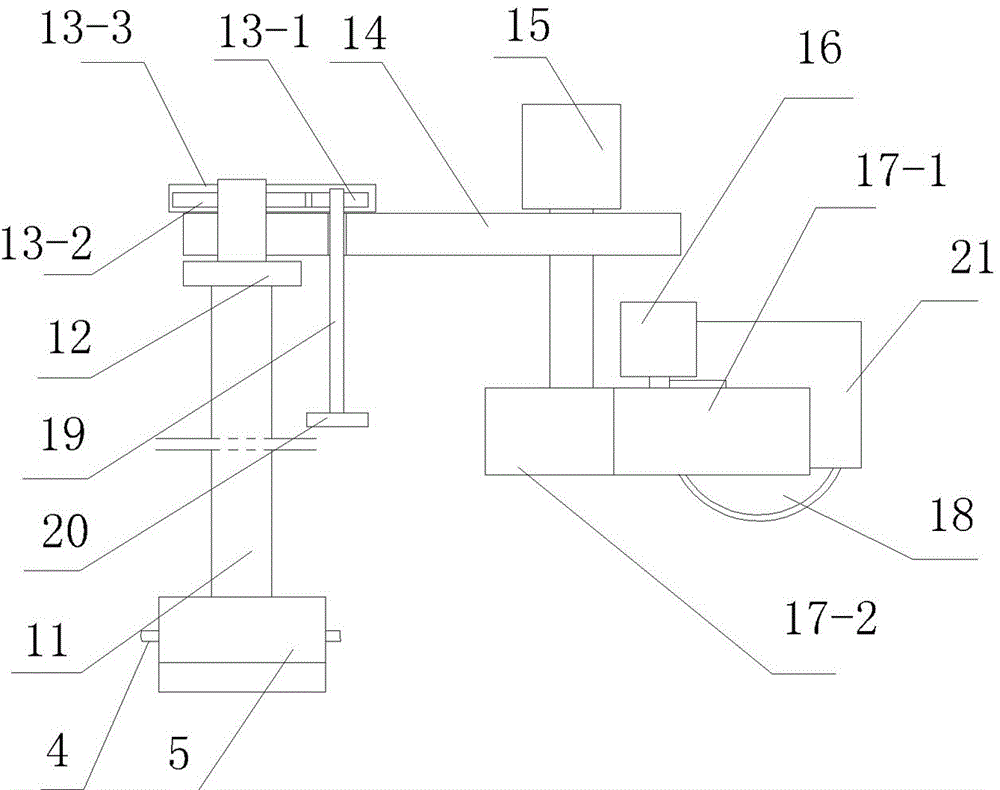

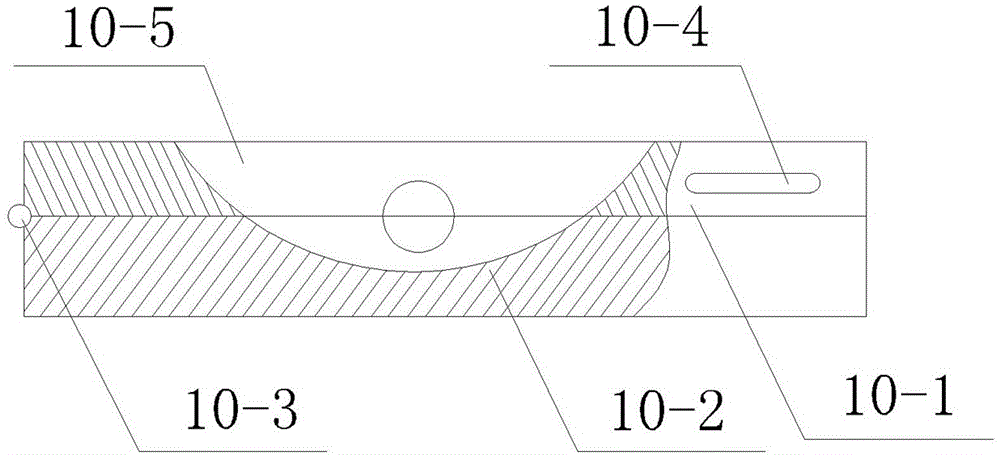

[0023] like figure 1 , figure 2 , image 3 As shown, the pipe elbow cutting device of the present invention includes two saw blade cutting machines and a conjoined elbow cutting mold 10, and the bottom of the saw blade cutting machine is provided with a saw blade spacing adjustment mechanism and a saw blade moving mechanism. The saw blade cutting machine includes a machine base 5, a column 11 and a rotating arm 14, a saw blade angle adjustment mechanism 13 is arranged between the rotating arm 14 and the column 11, one end of the rotating arm 14 is connected with the column 11 through clothing, and the other end is provided with a rotary cutting machine. Head 17, rotary cutting head 17 is connected with rotating arm 14 by lifting mechanism, and rotary cutting head 17 is provided with rotary cutting saw blade 18. Described lifting mechanism comprises lifting liquid cylinder 15, and lifting liquid cylinder 15 is installed on the rotating arm 14, and its telescoping end is conn...

Embodiment 2

[0029] see figure 1 , figure 2 , image 3 , The pipeline elbow cutting device of this embodiment includes two saw blade cutting machines and a conjoined elbow cutting mold 10, and a saw blade spacing adjustment mechanism and a saw blade moving mechanism are arranged at the bottom of the cutting machine. Described cutting machine comprises machine base 5, column 11 and rotating arm 14, and saw blade angle adjustment mechanism 13 is set between rotating arm 14 and column 11, and one end of rotating arm 14 is connected with column 11 through dress, and the other end is provided with rotary cutting head 17 , the rotary cutting head 17 is connected with the rotating arm 14 through a lifting mechanism, the rotary cutting head 17 is provided with a rotary cutting saw blade 18, and the rotary cutting saw blade 18 can also be provided with a protective cover 21. Described lifting mechanism comprises lifting liquid cylinder 15, and lifting liquid cylinder 15 is installed on the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com