cu-fe-c-ag alloy

A cu-fe-c-ag, alloy technology, applied in the field of composite materials, can solve the problems of coarsening of Fe phase, high cost of Ag alloying, reducing the stability of Fe phase fibers, etc., to improve electrical conductivity and tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

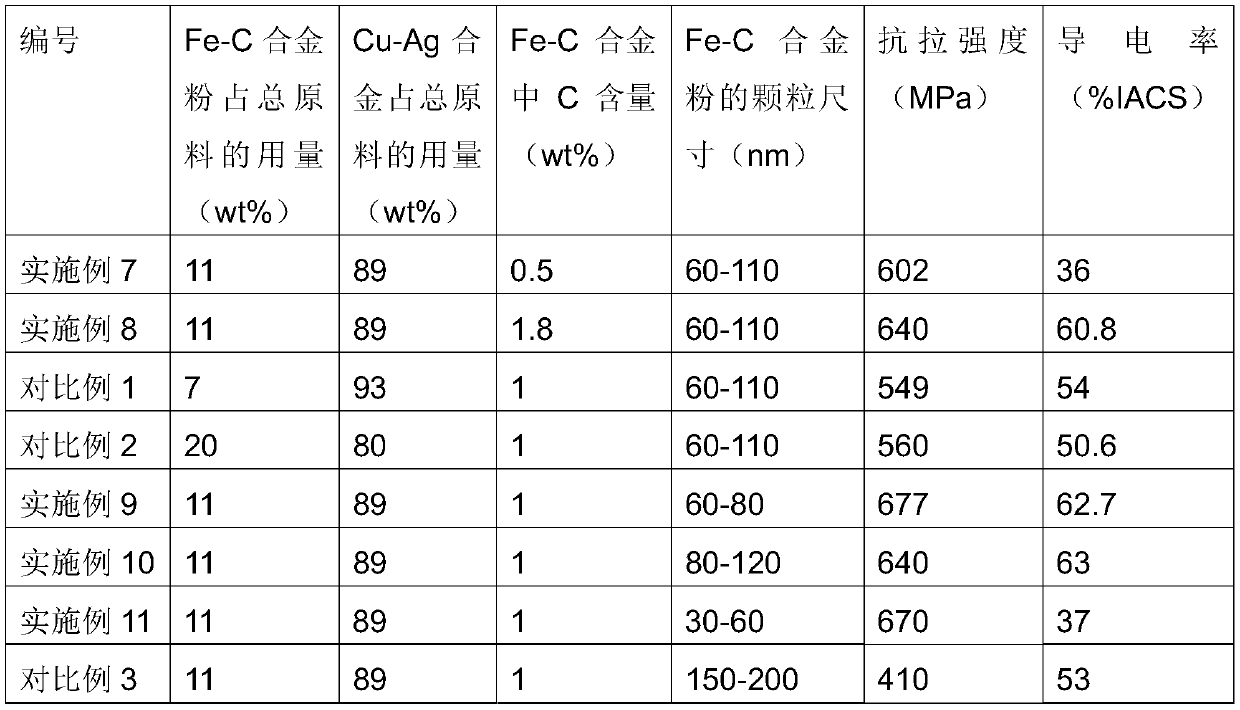

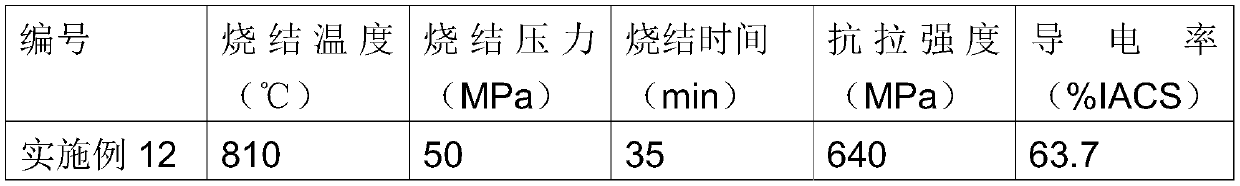

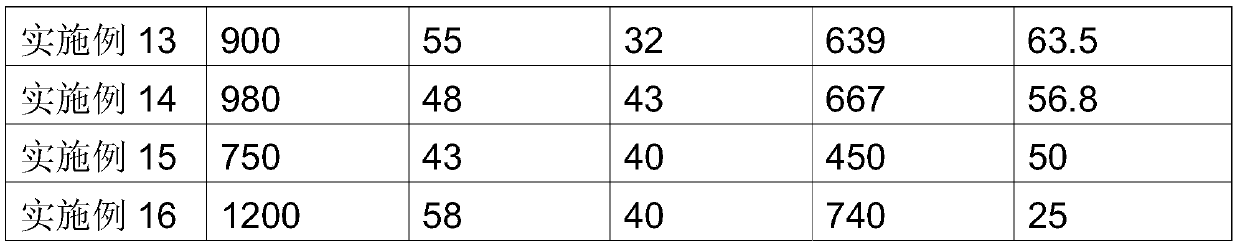

Examples

Embodiment 1

[0025] (1) Raw materials are prepared: the raw materials include Cu-Ag pre-alloyed powder of 10-50 μm and Fe-1.2wt% C pre-alloyed powder with a size of 70-120 nm, and the mass percentage of C in the Fe-C alloy powder is 1.2 wt%. Cu accounts for 88.5wt% of the raw material, Ag accounts for 0.5wt% of the raw material, Fe-C pre-alloyed powder accounts for 11wt% of the raw material,

[0026] (2) Ball milling and mixing: add grinding balls for mechanical powder mixing to obtain composite powder,

[0027] (3) Hot-press sintering: put the composite powder obtained in step (2) into a hot-press sintering furnace for sintering, the sintering temperature is 900°C, the sintering pressure is 50MPa, and the sintering time is 30min.

[0028] Cu-11wt%(Fe-C)-0.5wt%Ag alloy with uniform distribution of Fe-1.2wt%C particles was prepared.

[0029] Performance tests were carried out on the alloy prepared in this example, and the tensile strength of the alloy was 603 MPa, and the electrical conduc...

Embodiment 2

[0031] (1) Prepare raw materials: raw materials include Cu-Ag pre-alloyed powders of 10-50 μm and Fe-1.0wt% C pre-alloyed powders with a size of 70-120 nm, and the mass percentage of C in the Fe-C alloy powder is 1.0 wt%. Cu accounts for 84.5wt% of the raw material, Ag accounts for 0.5wt% of the raw material, Fe-C pre-alloyed powder accounts for 15wt% of the raw material,

[0032] (2) Ball milling and mixing: add grinding balls for mechanical powder mixing to obtain composite powder,

[0033](3) Hot-press sintering: put the composite powder obtained in step (2) into a hot-press sintering furnace for sintering, the sintering temperature is 800°C, the sintering pressure is 50MPa, and the sintering time is 30min.

[0034] A Cu-15wt% (Fe-C)-0.5wt%Ag alloy with uniform distribution of Fe-1.0wt%C particles was prepared.

[0035] Performance tests were performed on the alloy prepared in this example, and the tensile strength of the alloy was 678 MPa, and the electrical conductivity ...

Embodiment 3

[0037] (1) Raw materials are prepared: the raw materials include Cu-Ag pre-alloyed powder of 10-50 μm and Fe-1.1wt% C pre-alloyed powder with a size of 50-80 nm, and the mass percentage of C in the Fe-C alloy powder is 1.1 wt%. Cu accounts for 86.5wt% of the raw material, Ag accounts for 0.5wt% of the raw material, Fe-C pre-alloyed powder accounts for 13wt% of the raw material,

[0038] (2) Ball milling and mixing: add grinding balls for mechanical powder mixing to obtain composite powder,

[0039] (3) Hot-press sintering: put the composite powder obtained in step (2) into a hot-press sintering furnace for sintering, the sintering temperature is 820°C, the sintering pressure is 50MPa, and the sintering time is 30min.

[0040] Cu-13wt%(Fe-C)-0.5wt%Ag alloy with uniform distribution of Fe-1.1wt%C particles was prepared.

[0041] Performance tests were carried out on the alloy prepared in this embodiment, and the tensile strength of the alloy was 664 MPa, and the electrical cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com