Oil bath air filter

An air filter and oil bath type technology, which is applied in the direction of combustion air/combustion-air treatment, machine/engine, engine components, etc., can solve the problem of short service life of paper filter elements, unfavorable requirements for light weight of the whole machine, iron sheet The shell is easy to rust and other problems, and the effect of stable processing quality, light weight and long service life is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

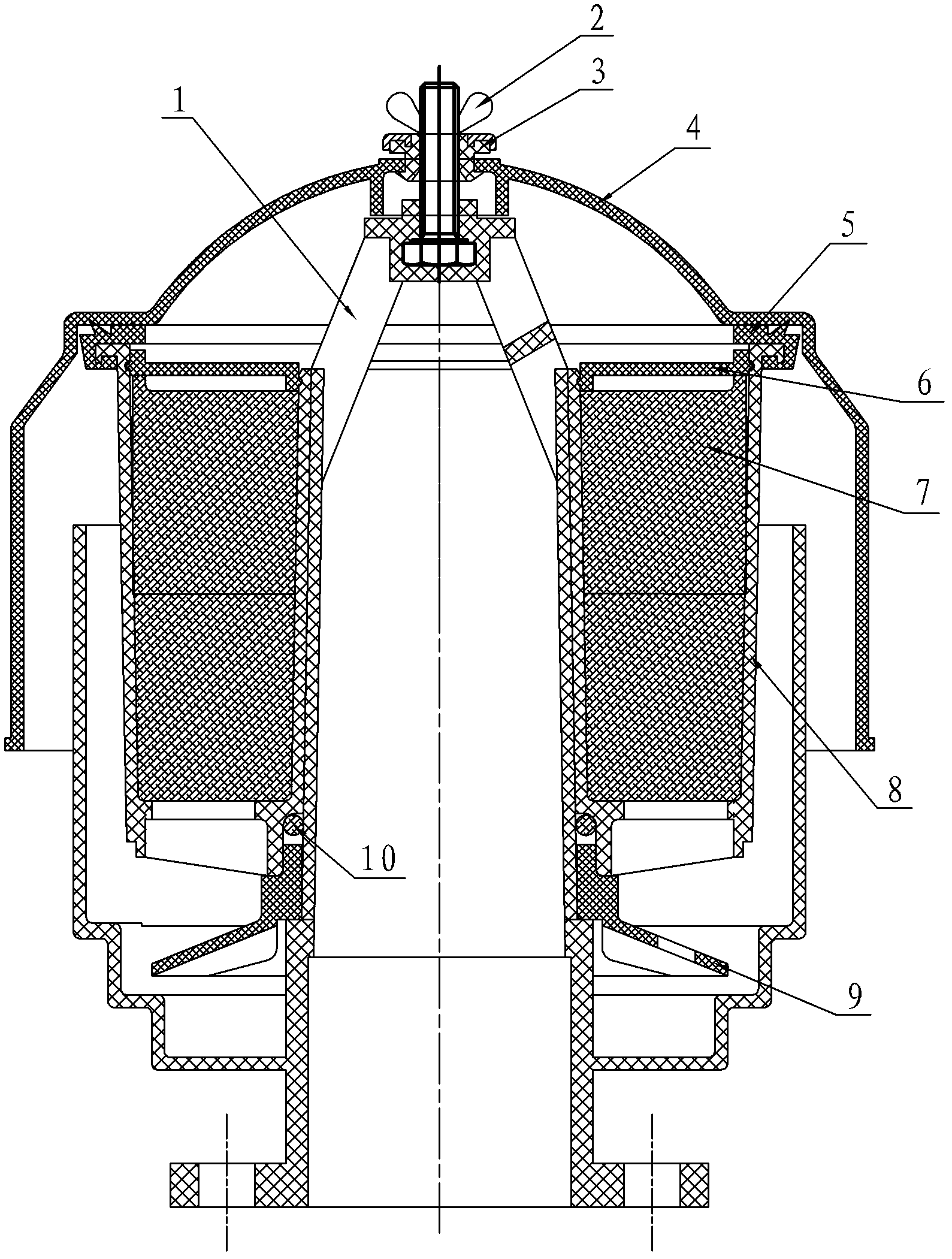

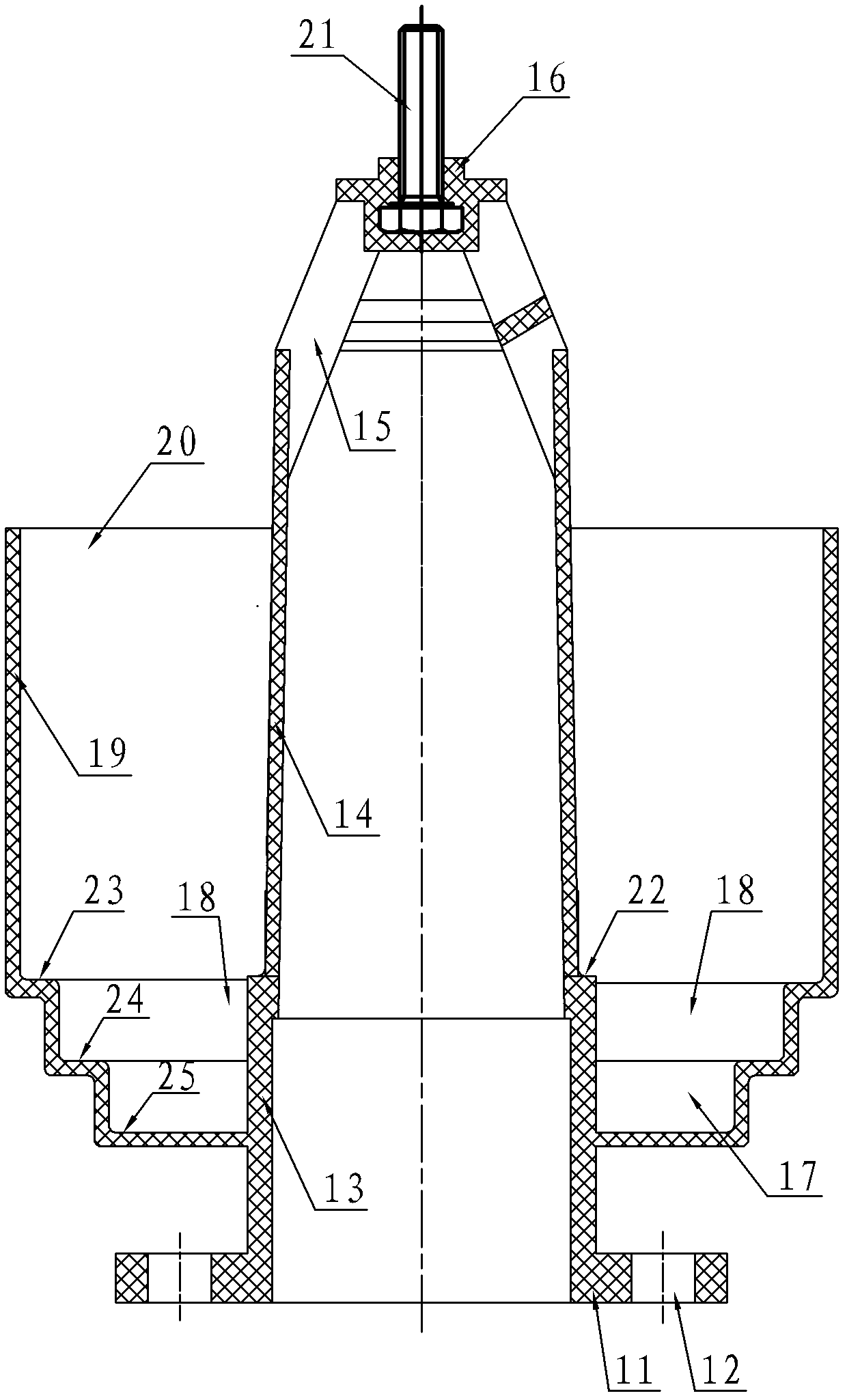

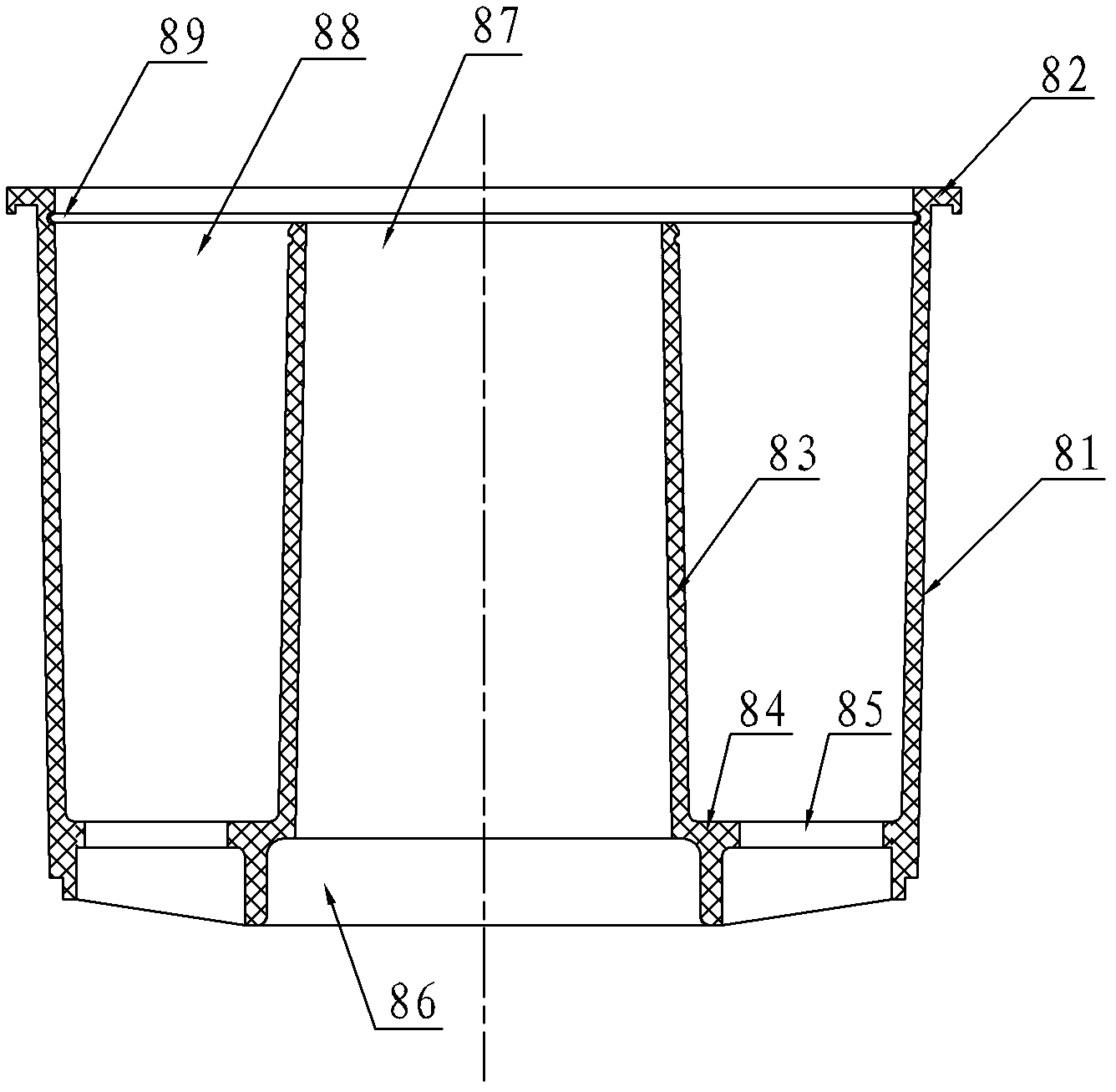

[0022] Embodiment 1: a kind of oil bath type air filter, as figure 1 As shown, it consists of plastic intake pipe seat 1, butterfly nut 2, anti-vibration sealing ring 3, plastic cover 4, upper port sealing ring 5, breathable filter element cover 6, oil-containing filter element 7, plastic filter element body 8, plastic oil retaining Disk 9 and axial sealing ring 10, the plastic intake pipe seat 1 such as figure 2 As shown, it consists of a connecting flange 11, a connecting hole 12, a central tube 13, a filter cup tube 14, a ventilating rib 15, a connecting top 16, an oil storage chamber 17, a plastic oil retaining pan cavity 18, a spacer ring 19, a filter element container Cavity 20, tightening bolt 21 and oil baffle step 22, the connecting flange 11 is located at the lower end of the central tube 13, the connecting hole 12 is set on the connecting flange 11, the filter cup tube 14 is located above the central tube 13, both Coaxial, oil baffle steps 22 are formed at the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com