Composite material and preparation method thereof

A composite material and mixed material technology, which is applied to the dazzling metal effect scratch-resistant high-hardness polycarbonate/ABS alloy material and its preparation, the composite material and its preparation field, and can solve the problem of no scratch-resistant and high-hardness polycarbonate. Ester, no preparation method for composite materials, etc., to achieve the effect of enhancing wear resistance, improving mechanical properties, and improving injection molding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]A kind of preparation method of composite material, the raw material of composite material takes various raw materials according to table 1 raw material formula, wherein under the condition of polycarbonate resin (300 ℃ / 1.2Kg ISO1133 (ASTM D-1238), its melt index is at 19g / 10min, Rockwell hardness (ISO2039-2ASTM D-785) is R120 (M75)). ABS resin (under the condition of 200°C / 5Kg, its melt index is 8.5g / 10min, and its refractive index is 1.57). Compatible toughening agents are all methyl methacrylate-butadiene-styrene terpolymers, methyl methacrylate-butadiene-styrene terpolymers have a core-shell structure, and the core is cross-linked Butadiene-styrene copolymer (Tg<-70℃), the shell is grafted polymethyl methacrylate (hard shell), methyl methacrylate-butadiene-styrene terpolymer is the core The weight percentage content of the shell structure methyl acrylate is 40%, the weight percentage content of butadiene is 35%, and the weight percentage content of styrene is 25%)....

Embodiment 2

[0050] A preparation method of a composite material, the preparation method of the composite material in Example 2 is the same as in Example 1, and the specific raw material ratio is shown in Table 1; the composite material product in Example 2 is tested according to the national standard, and the product performance data are shown in Table 2

Embodiment 3

[0052] A kind of preparation method of composite material, the composite material preparation method of embodiment 3 is the same as embodiment 1, and specific raw material ratio is shown in Table 1; The composite material product of embodiment 3 is tested according to national standard, and product performance data is as shown in table 2

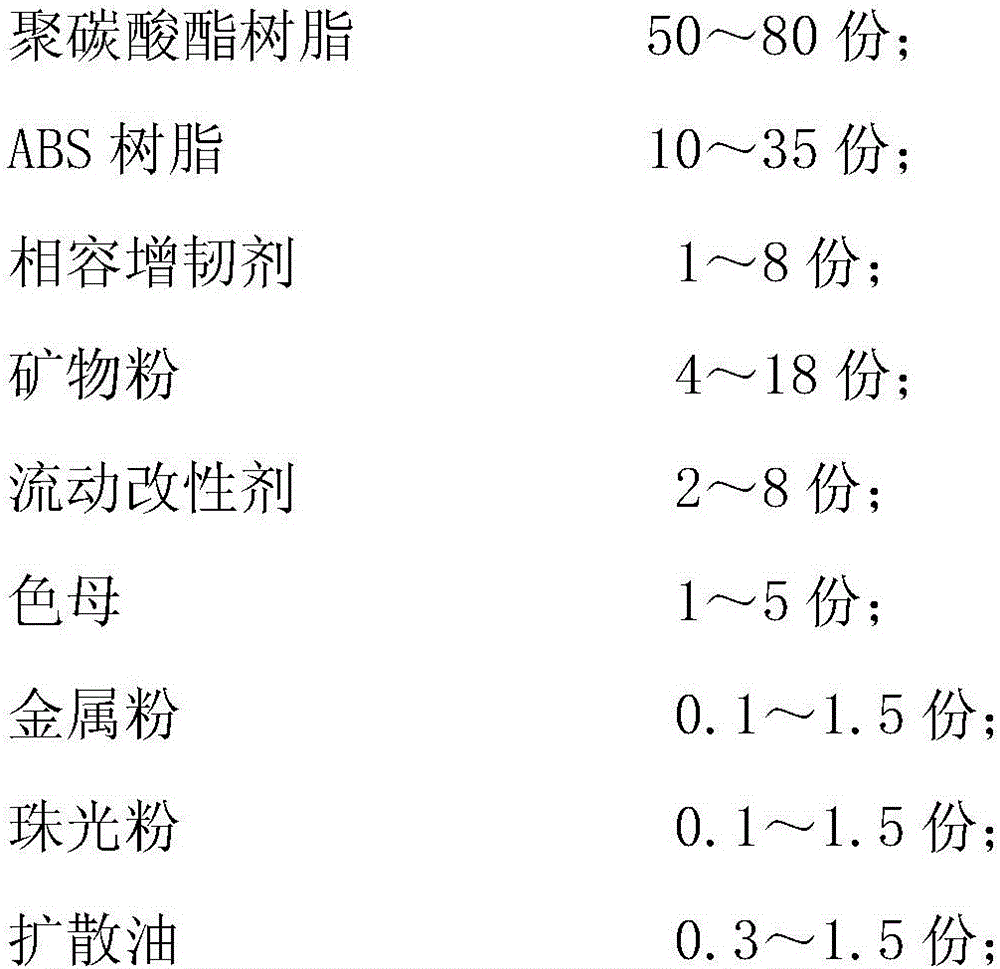

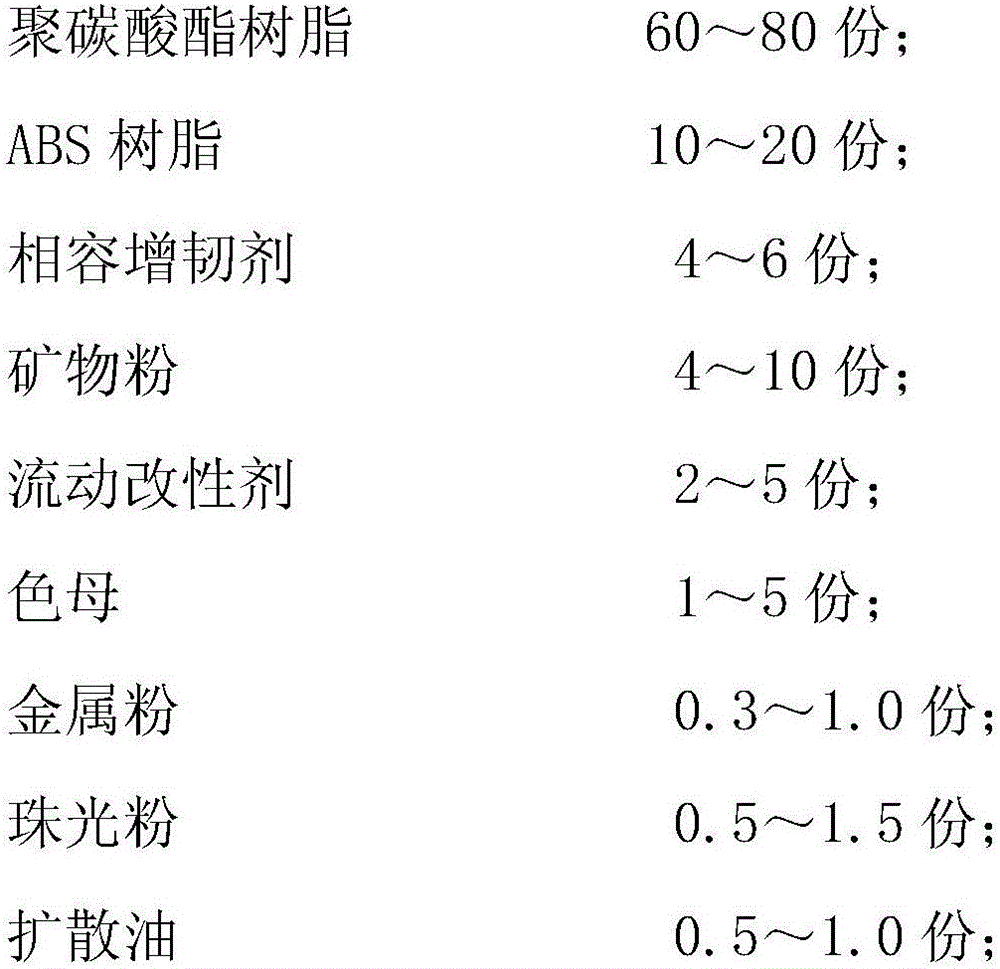

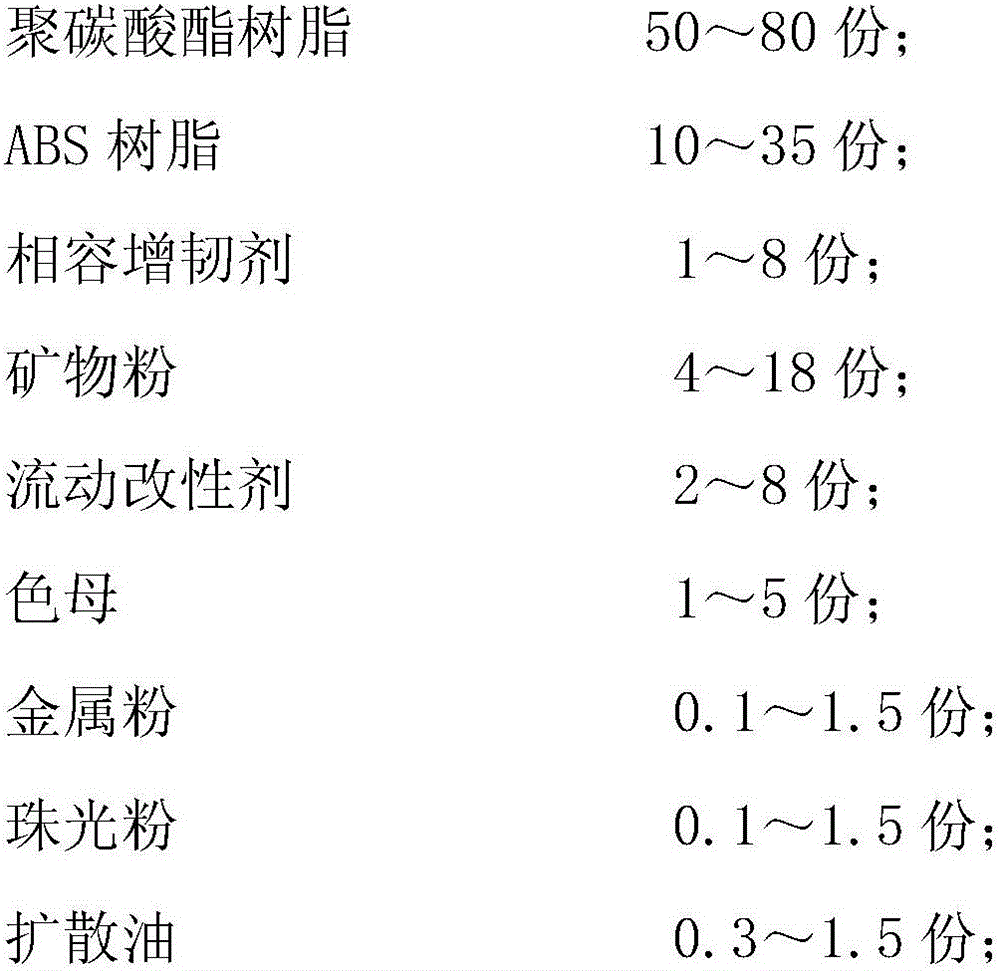

[0053] Table 1: Raw materials and proportions of composite materials

[0054] Unit: kg

[0055] components Example 1 Example 2 Example 3 Comparative example 1 Comparative example 2 polycarbonate 50 80 65 50 80 ABS resin 10 35 22.5 10 35 Compatible Toughener 1 8 4.5 1 8 mineral powder 4 18 11 0 18 flow modifier 2 8 5 0 0 masterbatch 1 5 3 0 0 metal powder 0.1 1.5 0.8 0 0 Pearl powder 0.1 1.5 0.8 0 0 Diffuser oil 0.3 1.5 0.9 0 0

[0056] Table 2: Properties of composite materials prepared by composite material preparation methods

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com