Root canal filling paste capable of being stored and injected

A paste-filled, injection-type technology, used in dental preparations, medical science, dentistry, etc., can solve the problems of affecting the performance of the paste, unable to completely seal the apical foramen, and expensive paste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

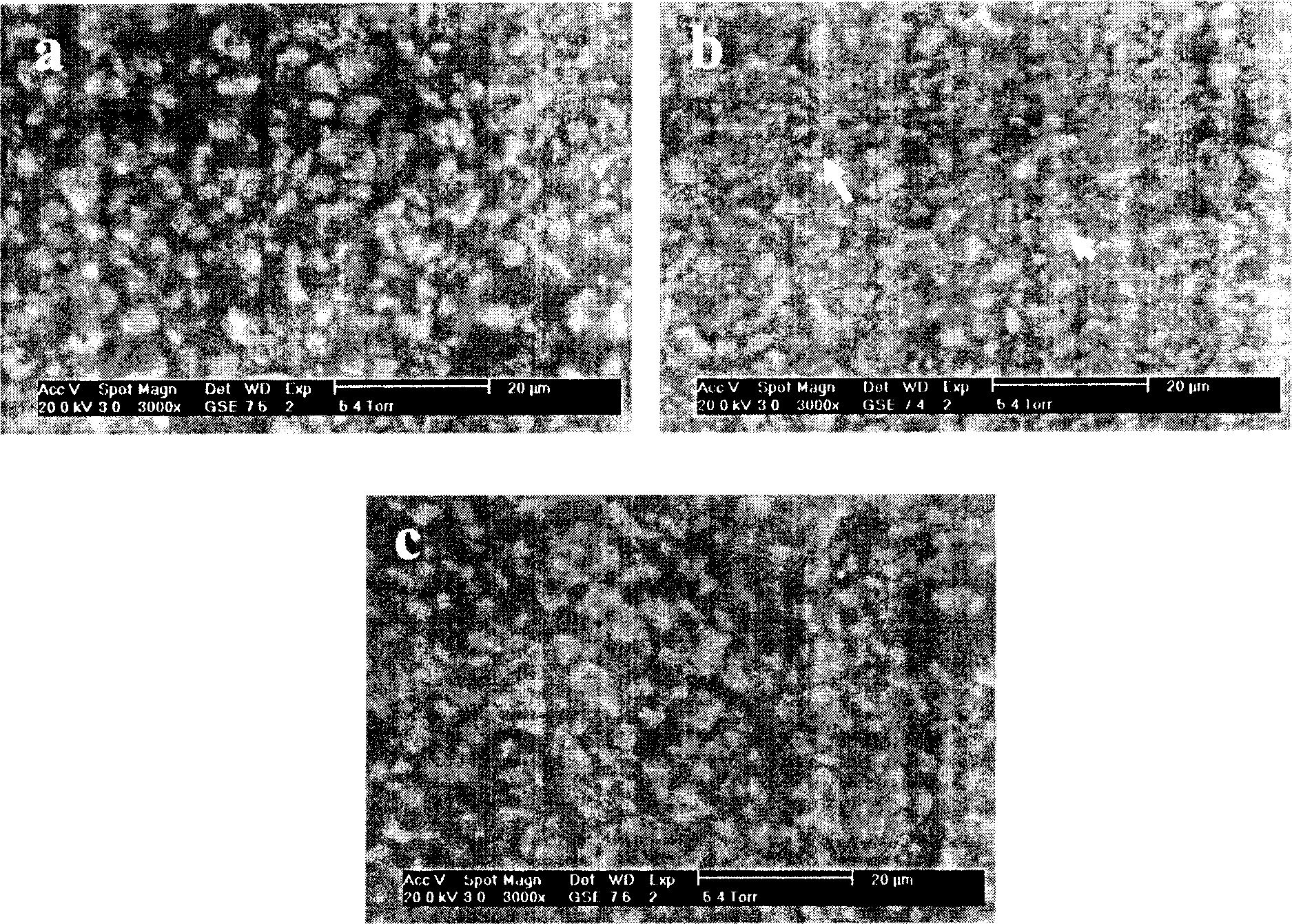

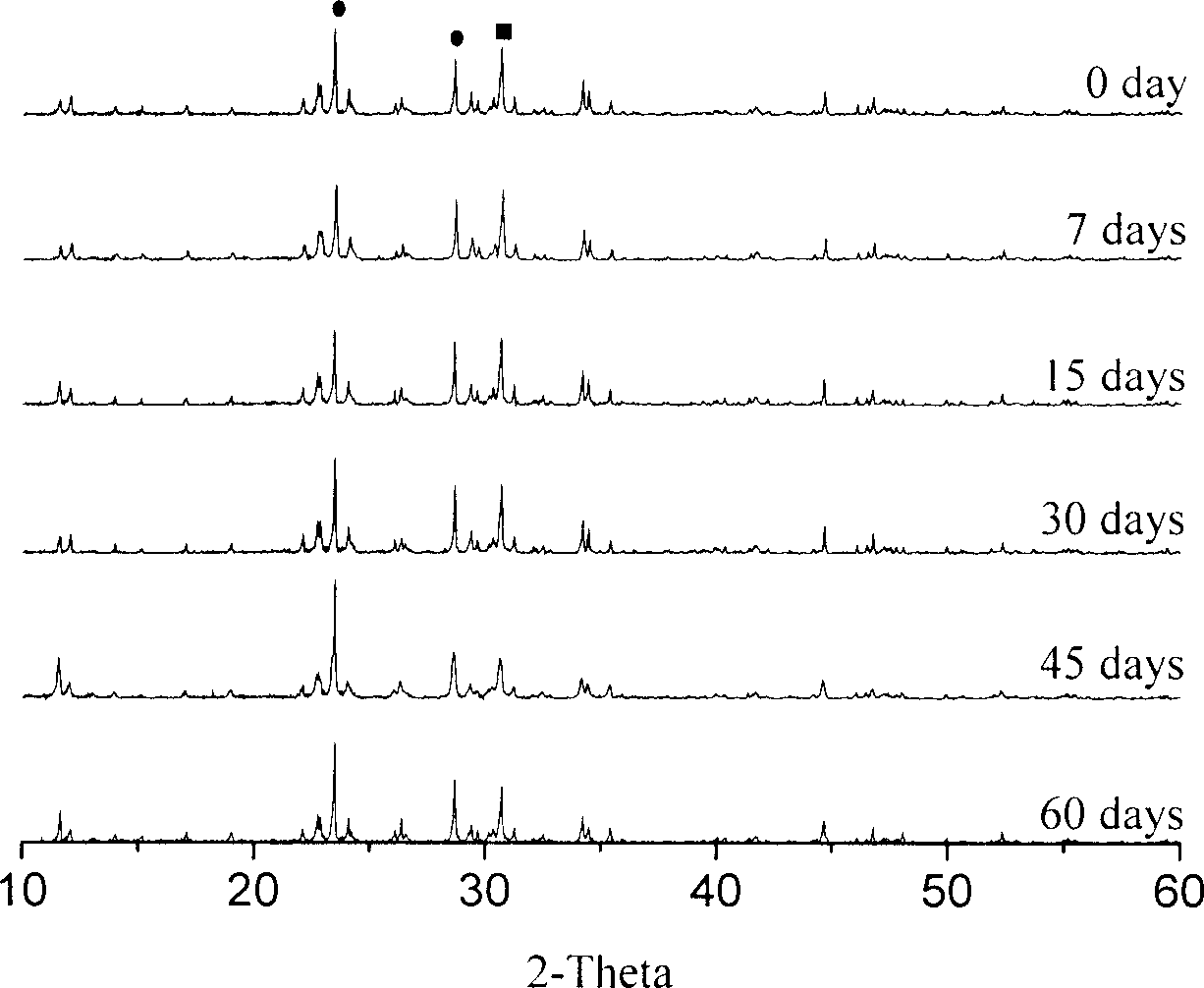

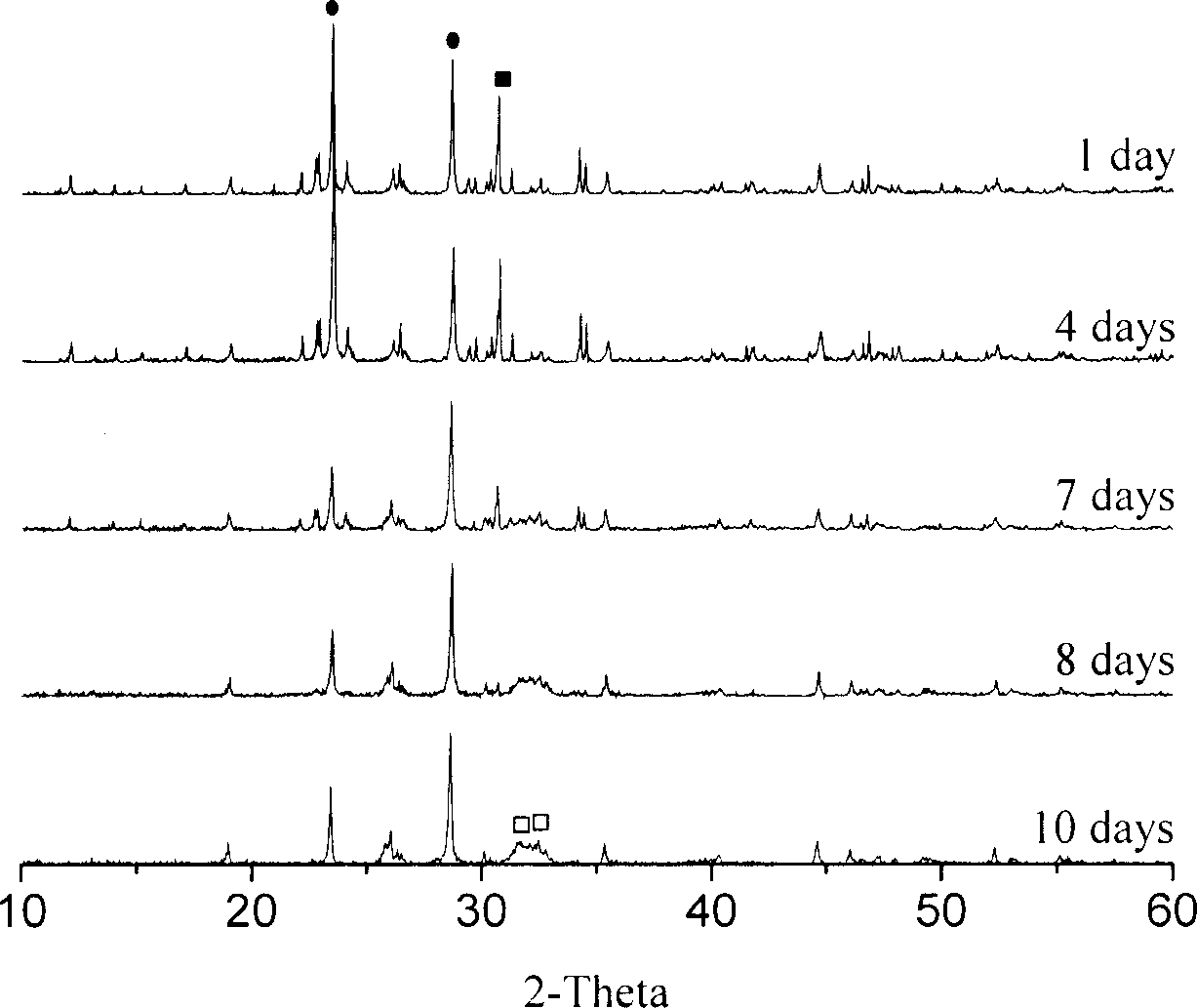

[0016] Get calcium phosphate powder 64g, iodoform 16g mix and make solid powder and divide into two parts of equal mass. Then 8.8g glycerol, 4g sorbitol, 1.4g chitosan oligosaccharide (molecular weight is less than 5000), 0.06gNa 2 HPO 4 Add it to 5.74g distilled water to prepare a solidified solution; another part of the solidified solution is a mixed aqueous solution that does not contain a thickener (oligochitosaccharide) and other solutes remain unchanged. Thoroughly mix the above two solutions and solid powder respectively to make a root canal filling paste, and pour it into a special syringe for root canal filling. After the paste was stored at 4°C and 50% RH for 7 days, the changes of the particles were observed with an environmental scanning electron microscope, and compared with the particles of the current paste. figure 1 It shows that the distance between the particles of the paste without the thickener becomes smaller, some particles are dissolved, and the partic...

Embodiment 2

[0022] Get calcium phosphate powder 1.8g, iodoform 1.2g mix and make solid powder. Then 0.55g glycerol, 0.03g sodium alginate, 0.05g chitosan oligosaccharide (molecular weight is less than 5000), 0.004gNa 2 HPO 4 Add to 0.366g of distilled water to prepare solidified liquid. Thoroughly mix the above powder and solidification solution to make a root canal filling paste, pour it into a special syringe for root canal filling, and store it in an environment of 4° C. and 50% RH. After two months, the properties of the root filling paste did not change, and the paste was injected into the prepared root canal, and the results showed that the filling effect was satisfactory.

Embodiment 3

[0024] Get calcium phosphate powder 2.4g, iodoform 0.6g mix and make solid powder. Then 2.5g polyethylene glycol 400, 0.05g sodium carboxymethylcellulose, 0.065g Na 2 HPO 4 , 0.01g NaH 2 PO 4 Add it to 2.375g distilled water to prepare a solidified liquid. Thoroughly mix the above powder with the solidification solution to make a root canal filling paste, pour it into a root canal filling syringe, and store it in an environment of 4° C. and 50% RH. After two months, the properties of the root filling paste did not change, and the paste was injected into the prepared root canal, and the results showed that the filling effect was satisfactory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com