Electric injection device for injection molding machine

An injection device and injection molding machine technology, applied in the field of injection devices, can solve the problems of reducing the injection performance of the injection molding machine, increasing the injection start-up time, etc., and achieve the effects of shortening the injection start-up time, improving the injection performance, and realizing mutual independence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

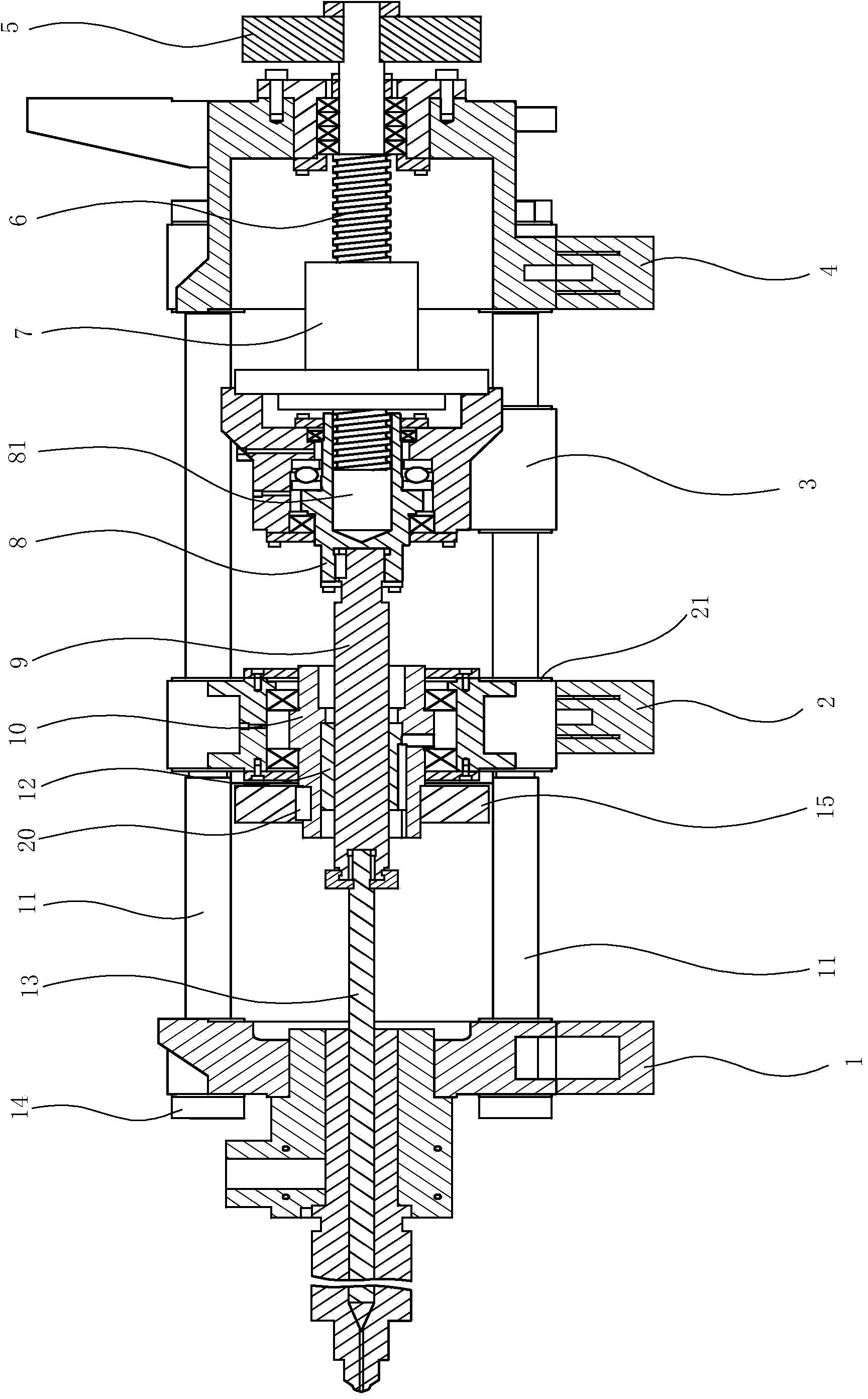

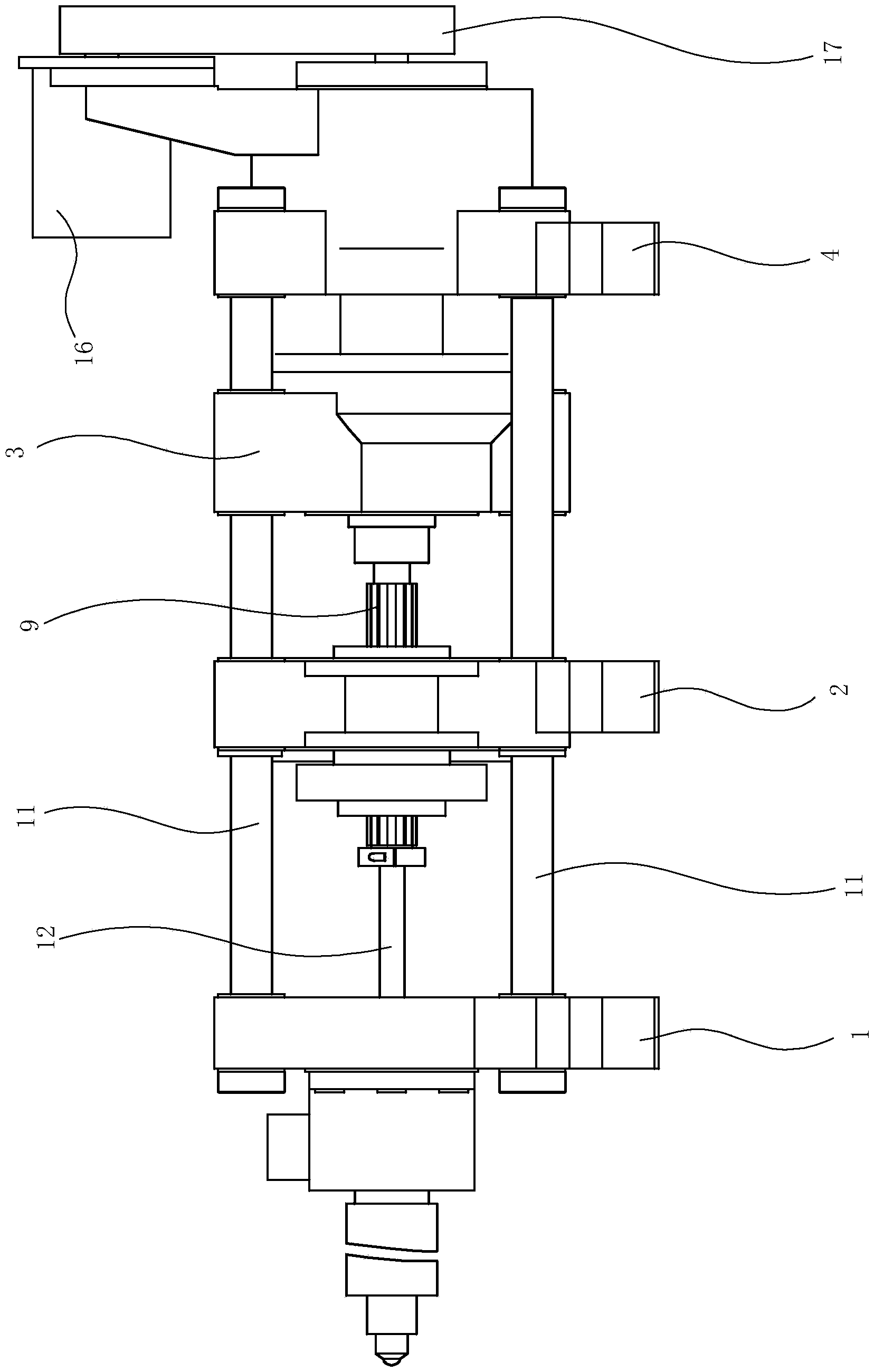

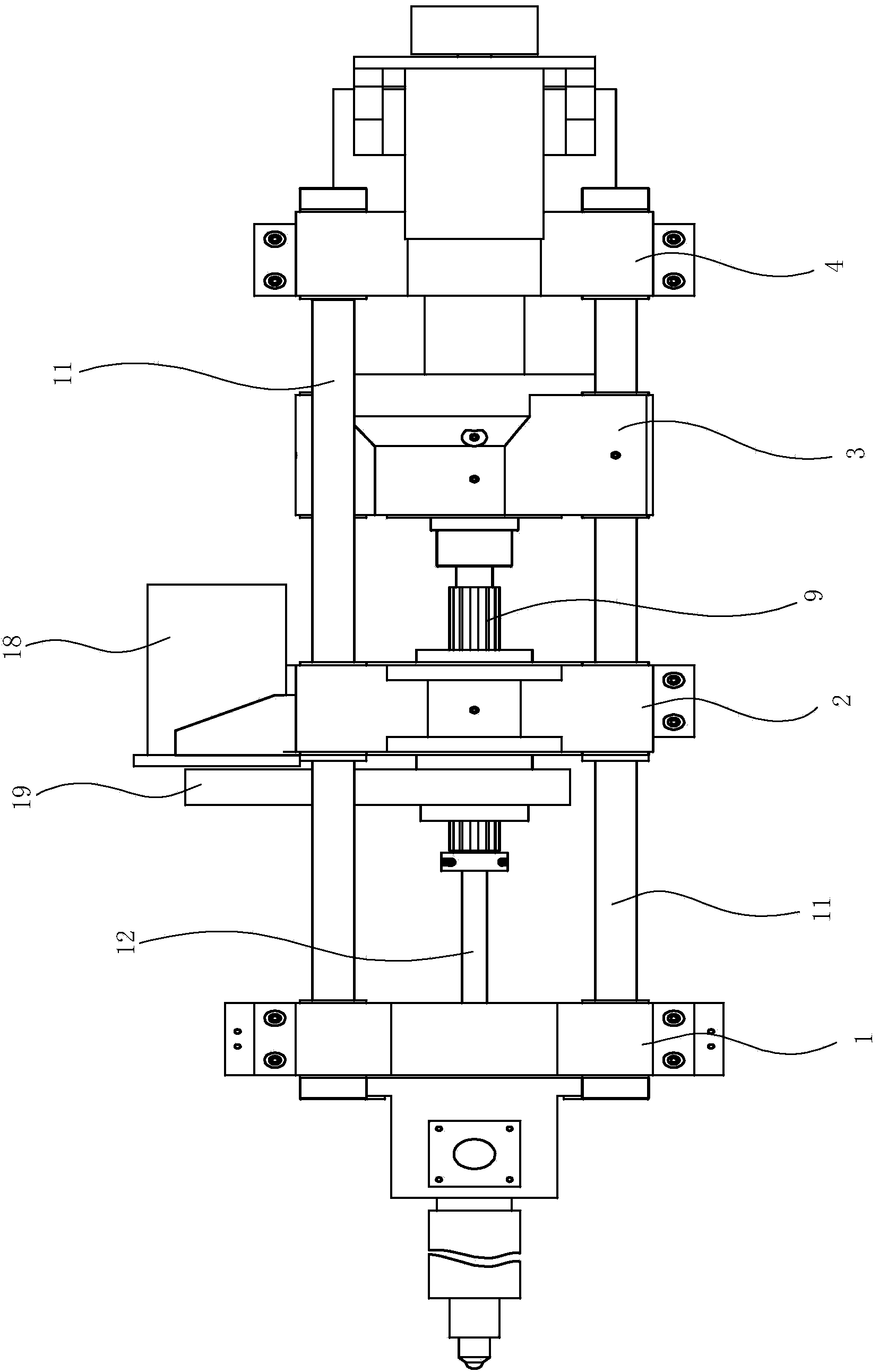

[0016] Such as Figures 1 to 3 As shown, the electric injection device of the injection molding machine in this implementation includes an injection front plate 1, an injection tail plate 4, an injection rod 11, a rod nut 14, a screw 13, a roller screw 6, a nut 7, an injection motor 16, and an injection synchronous Belt 17, injection driven wheel 5, injection moving plate 3, injection middle plate 2, pressure transmission shaft 8, spline shaft 9, spline sleeve 12, transmission shaft 10, melt glue motor 18, melt glue synchronous belt 19, melt glue slave The ball screw pair is formed between the moving wheel 15, the flat key 20, the nut 7 and the roller screw 6, and the spline pair is formed between the spline sleeve 12 and the spline shaft 9.

[0017] Among them, four injection rods 11 are pierced between the injection front plate 1 and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com