Rain shoe injection molding device

A technology of injection molding equipment and rain boots, which is applied to footwear, other household appliances, household appliances, etc., can solve the problems of inability to meet mass production, uneven quality of rain boots, low production efficiency, etc., and achieves reduction of manual labor and easy operation. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

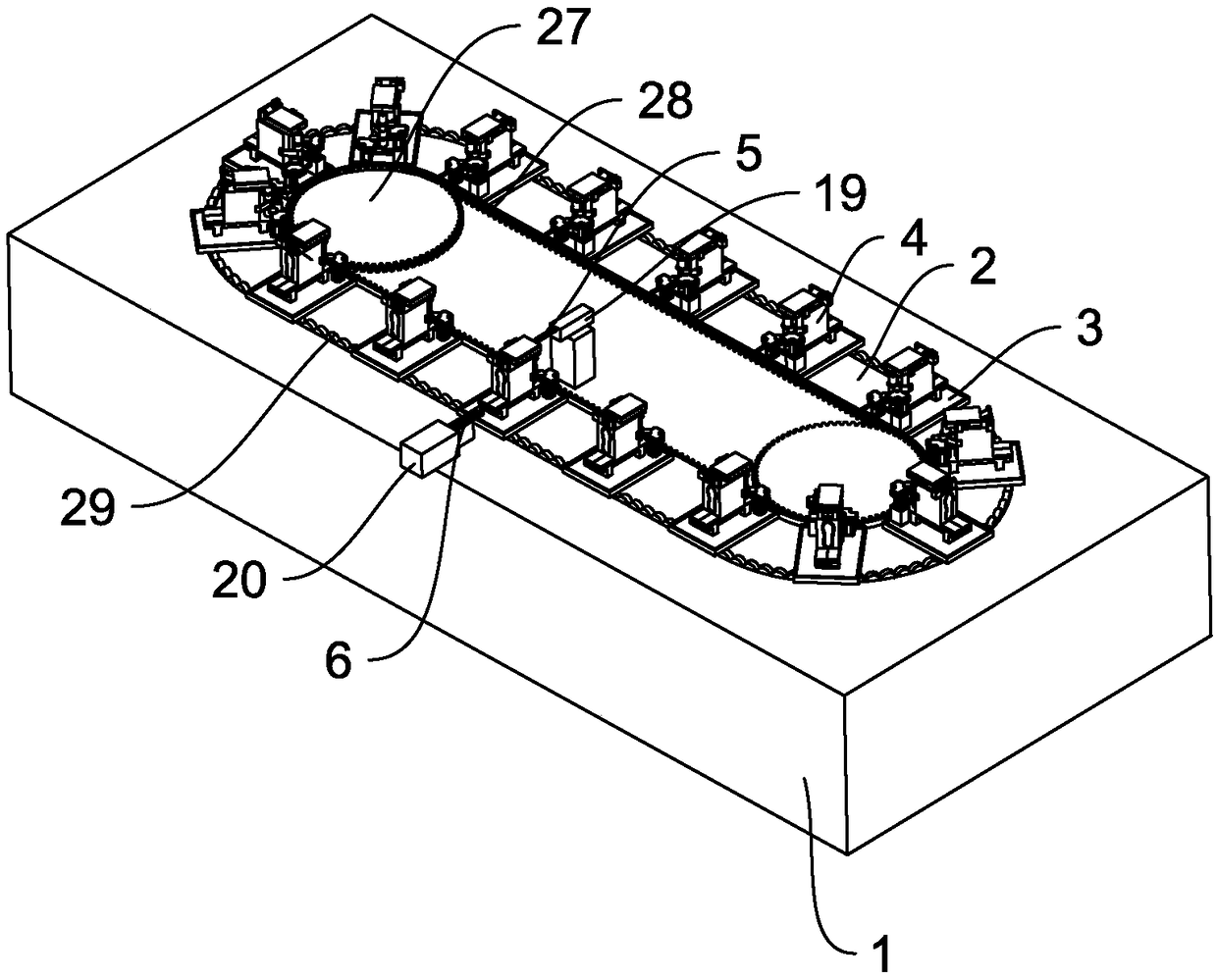

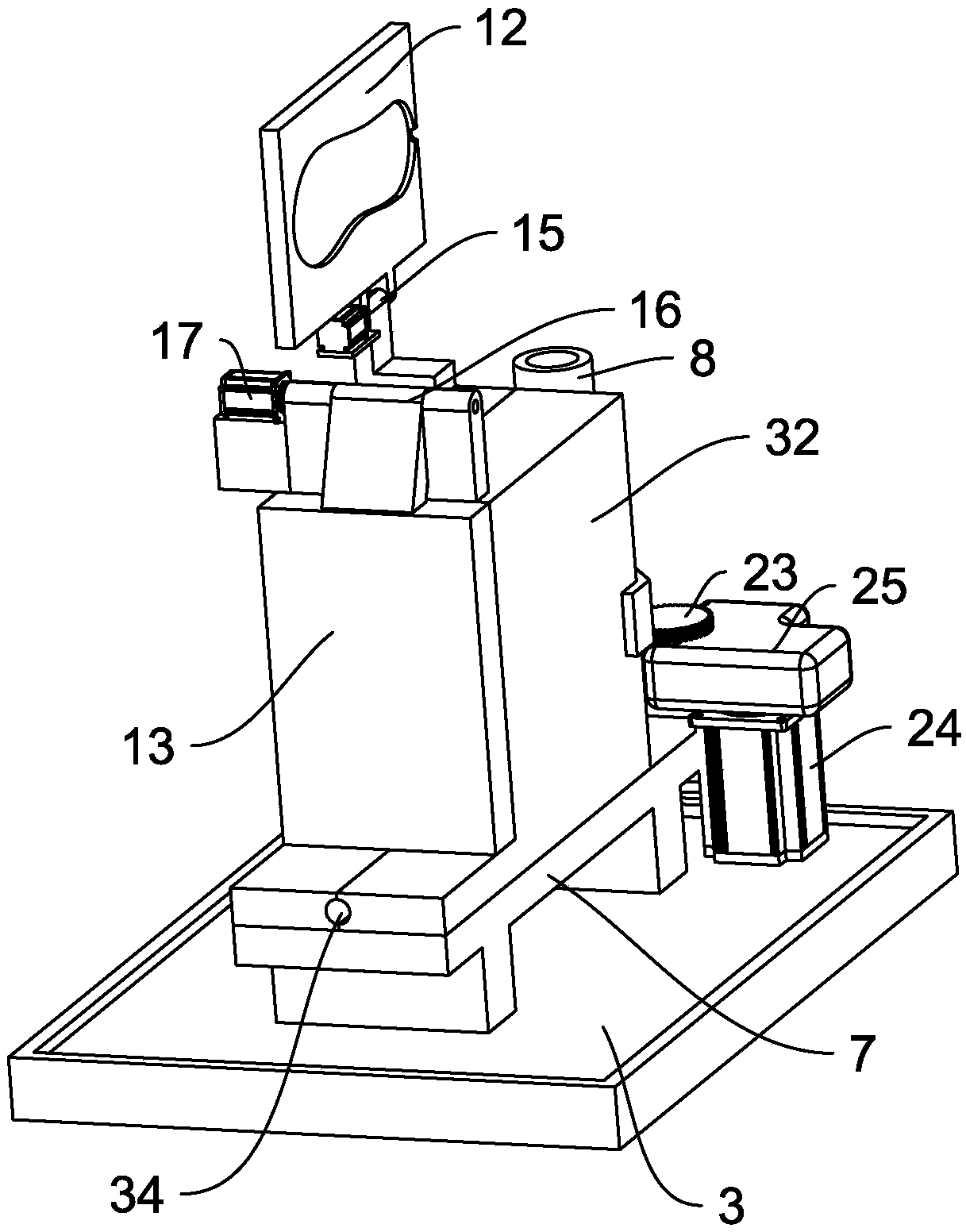

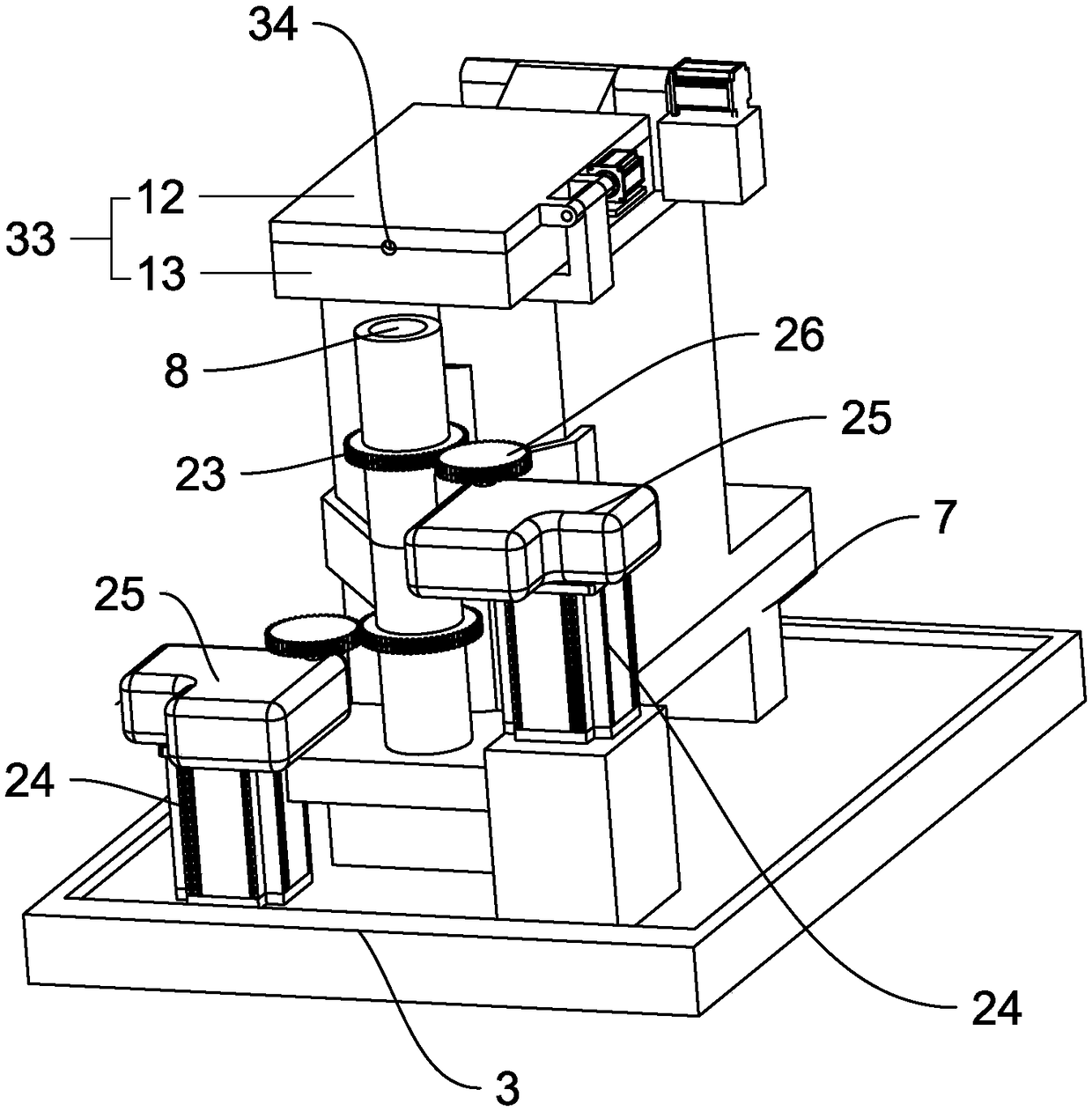

[0034] see figure 1 As shown, a rain boot injection molding equipment includes a frame 1. A circle of chute 2 is provided on the upper surface of the frame 1. The chute 2 is in the shape of a middle rectangle and circular rings at both ends. There are several workstations 3 arranged at intervals, each workstation 3 is provided with a shoe mold 4 composed of a shoe upper mold 32 and a sole mold 33, the workstations 3 are rolled and supported in the chute 2, and the specific structure is as follows: Several rollers 29 are arranged on the inner bottom of the chute 2 along its circumference, and the station 3 is supported on the rollers 29; the station 3 is driven by a transmission mechanism to move along the circumference of the chute 2, and the specific transmission structure is: It includes two driving wheels 27 arranged on the upper surface of the frame 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com