Method for mining deep and ultra-deep thick oil pools by using double horizontal well fire flooding drainage

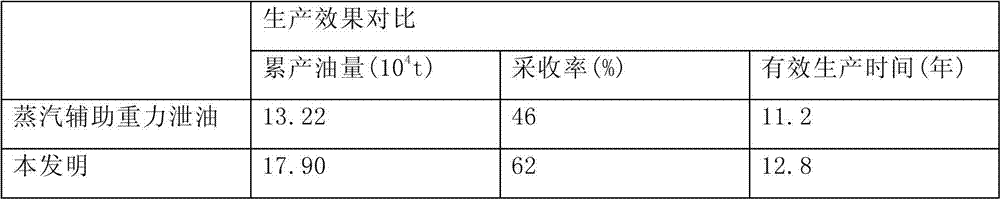

A mining method and ultra-deep technology, which can be used in the development of fluids, earth-moving drilling, wellbore/well components, etc. The effect of oil belt area, low safety risk, high recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

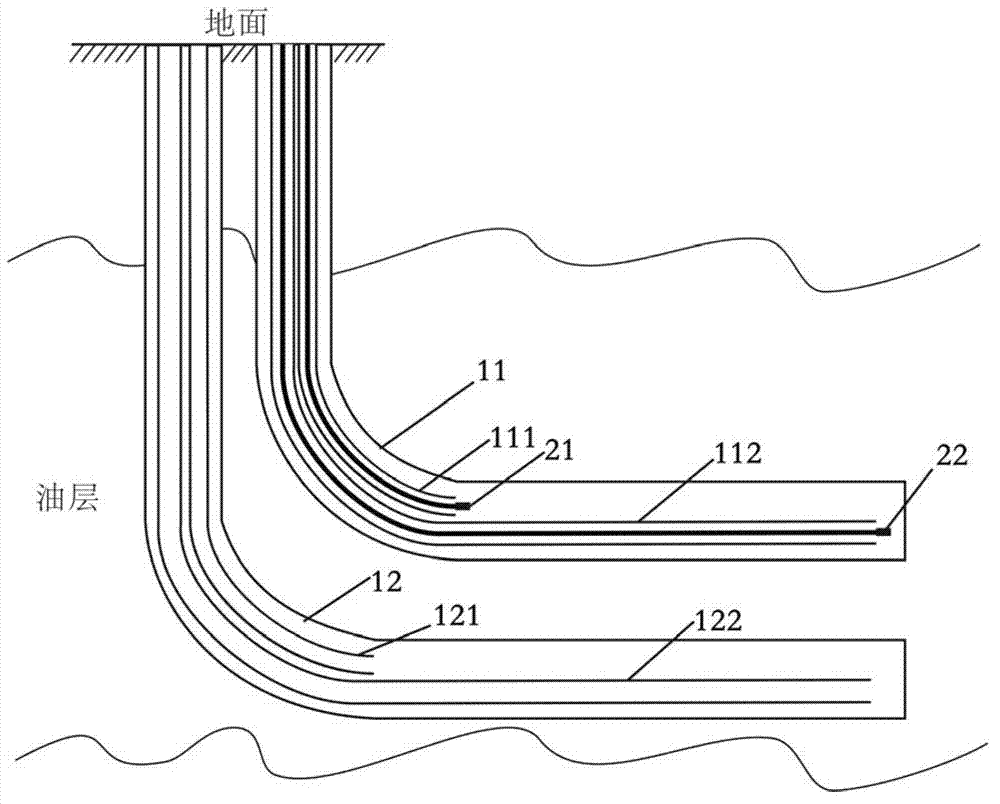

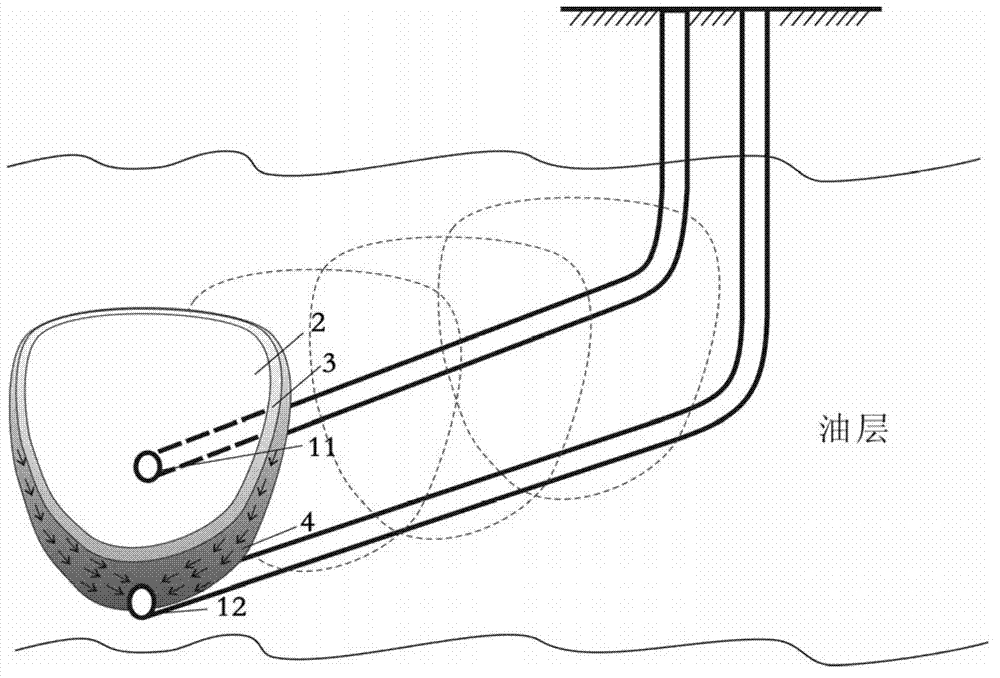

[0054] Such as figure 1 , figure 2 As shown, the present invention proposes a kind of deep and ultra-deep heavy oil reservoir dual-horizontal well fire flooding oil drainage production method, the main oil layer of this heavy oil reservoir is buried deep, the average buried depth is 1850m, the original reservoir pressure 16MPa, the original The temperature of the reservoir is 69°C; the viscosity of crude oil is high, and the viscosity of crude oil at the reservoir temperature is 480,000 centipoise, and the effective average thickness of the reservoir is 19m.

[0055] The deep and ultra-deep heavy oil reservoir double-horizontal well fire flooding oil drainage production method of the present invention comprises the following st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com