Bullet puller of large-caliber machine gun bullet

A large-caliber, bullet-puller technology, which is applied to grapple hooks, weapon accessories, offensive equipment, etc., can solve the problem of inability to meet the clamping force of large-caliber bullets, and achieve the effects of simple structure, low cost, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

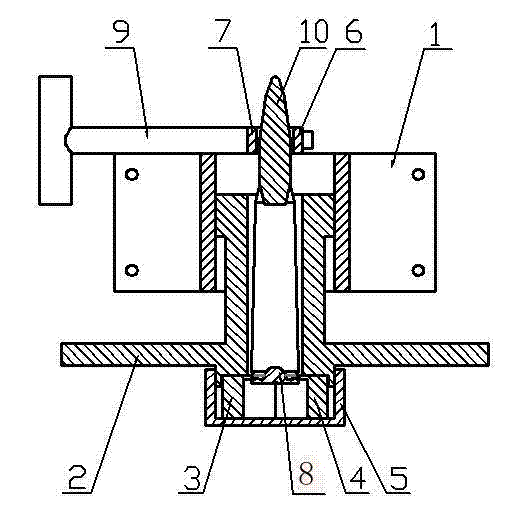

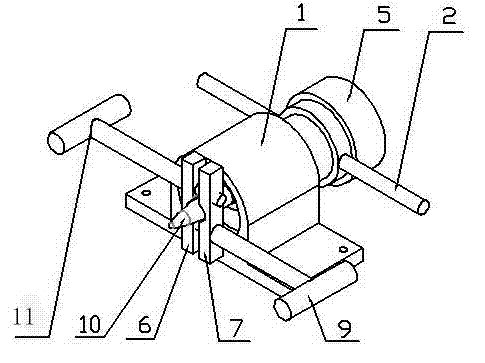

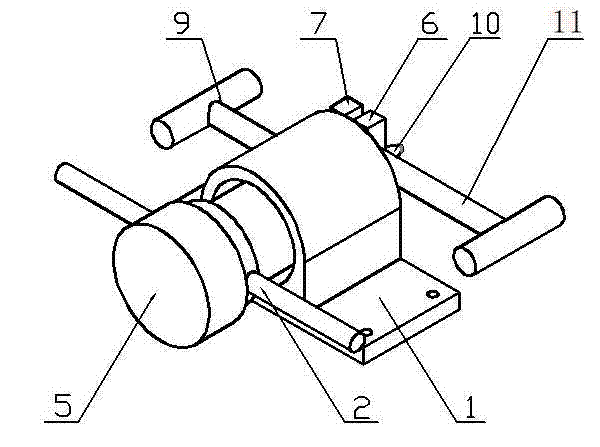

[0012] The outer diameter of the head of the pulling screw 2 is milled with a 20mm long thread to cooperate with the thread of the base. The inside of the pulling screw 2 is milled with a through hole with an inner diameter of 26mm that runs through the head and tail to ensure that the bullet is inserted smoothly. The rear end of the pulling screw rod 2 is milled with an inner hole with a diameter of 50 mm and a height of 5 mm to ensure that the left locking flap 3 and the right locking flap 4 can be smoothly put into the pulling screw rod 2 and positioned. Pulling screw rod 2 afterbody outer diameters are milled with thread, and use with the internal thread of protective cover 5. The left flap 3 and the right flap 4 are two symmetrical semicircular flaps with a height of 20mm and an outer diameter of 49mm. A semicircular hole with a height of 18.5mm and a diameter of 30mm is milled in the middle of each flap. The mm diameter is slightly larger than the semicircular hole of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com