High-frequency error detecting apparatus and method for heavy caliber heavy relative aperture aspherical mirror

An aspherical mirror and relative aperture technology, applied in the field of optical testing, can solve the problems of lengthening the optical path and increasing the load, and achieve the effect of improving the lateral resolution, simple structure, and increasing the vertical measurement range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

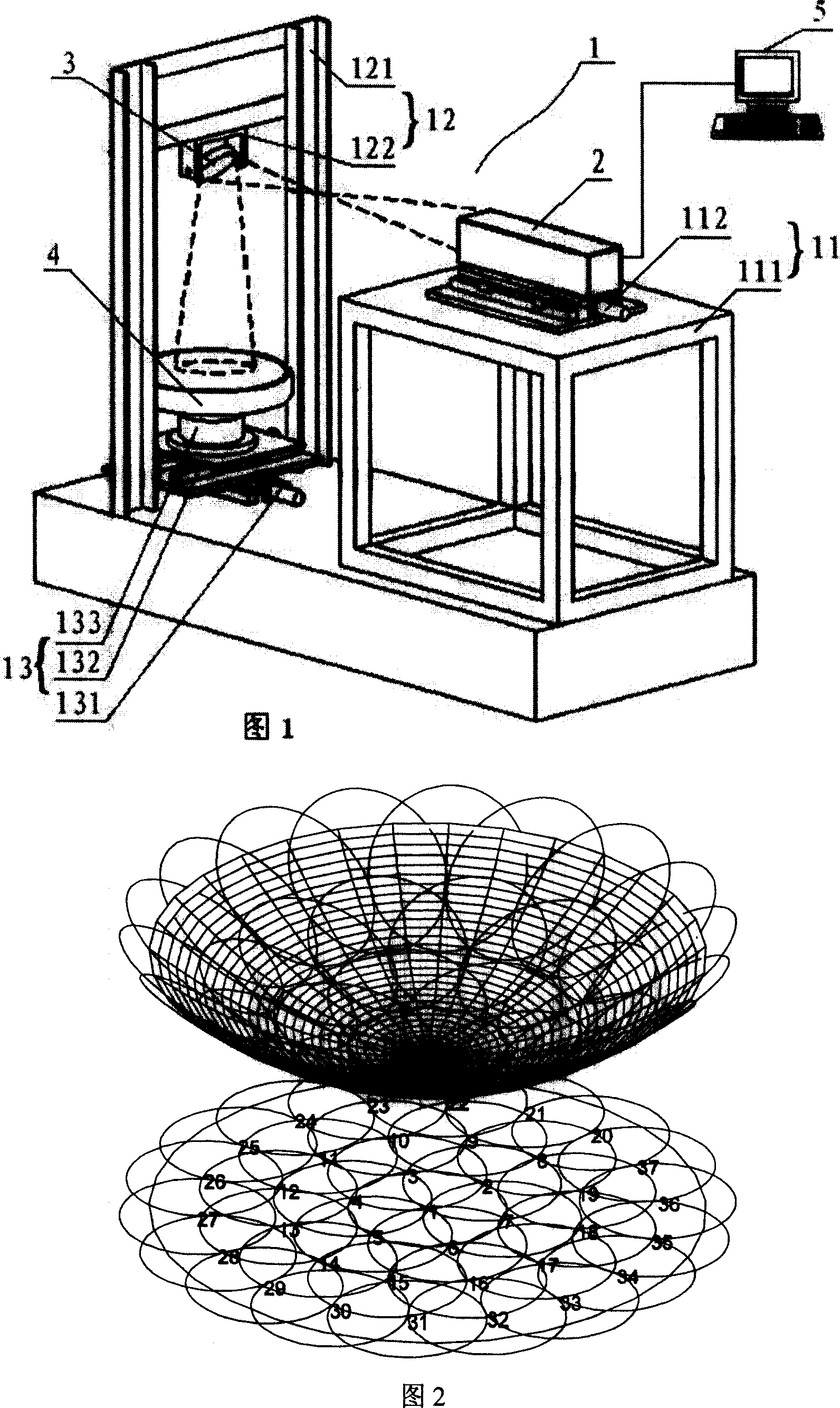

[0035] As shown in Figure 1, the high-frequency error detection device for large-diameter and large-relative-aperture aspheric mirrors of the present invention has a five-axis motion adjustment platform 1, including an interferometer focusing platform 11, and a yaw reflector positioned in front of the interferometer focusing platform. The yaw platform 12, the three-dimensional motion adjustment platform 13 of the measured aspheric mirror located below the yaw mirror yaw platform; 13 is respectively equipped with laser wave front interferometer 2, deflection mirror 3, multi-point support mechanism 4 of the measured aspheric mirror, and main control computer 5 with built-in detection data processing algorithm program is connected with laser wave front interferometer 2.

[0036] The interferometer focusing platform 11 includes an angle steel welding seat 111 and a focusing movement Z-axis assembly 112. The focusing movement Z-axis assembly 112 is composed of an AC servo motor, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com