Adjustable Gas Block

a gas block and adjustment technology, applied in the direction of weapons, weapon components, sighting devices, etc., can solve the problems of unsatisfactory characteristics, and achieve the effect of avoiding the use of silencers and being easily adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

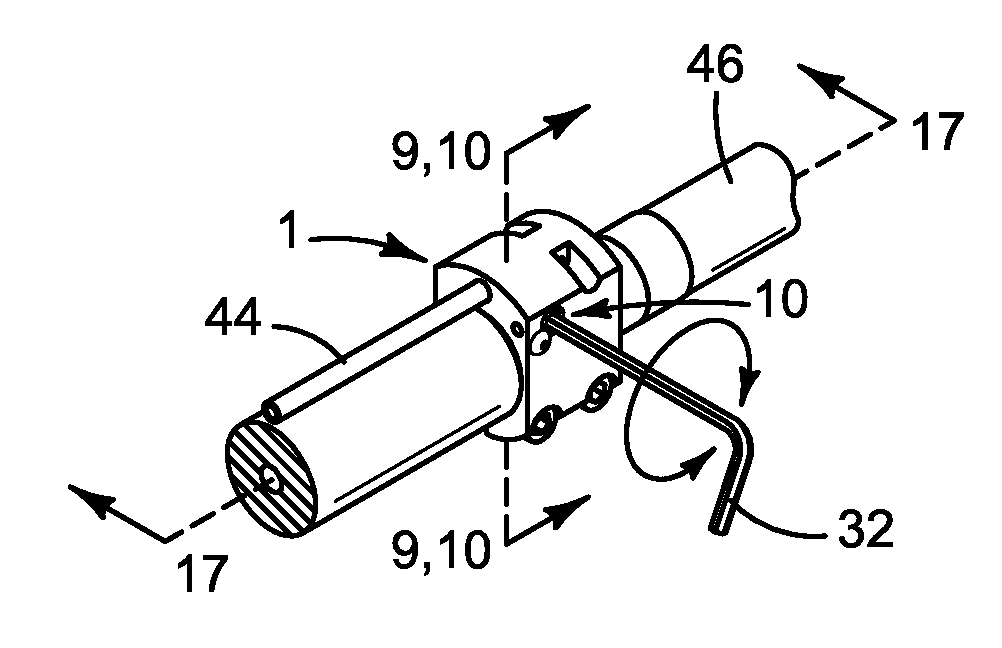

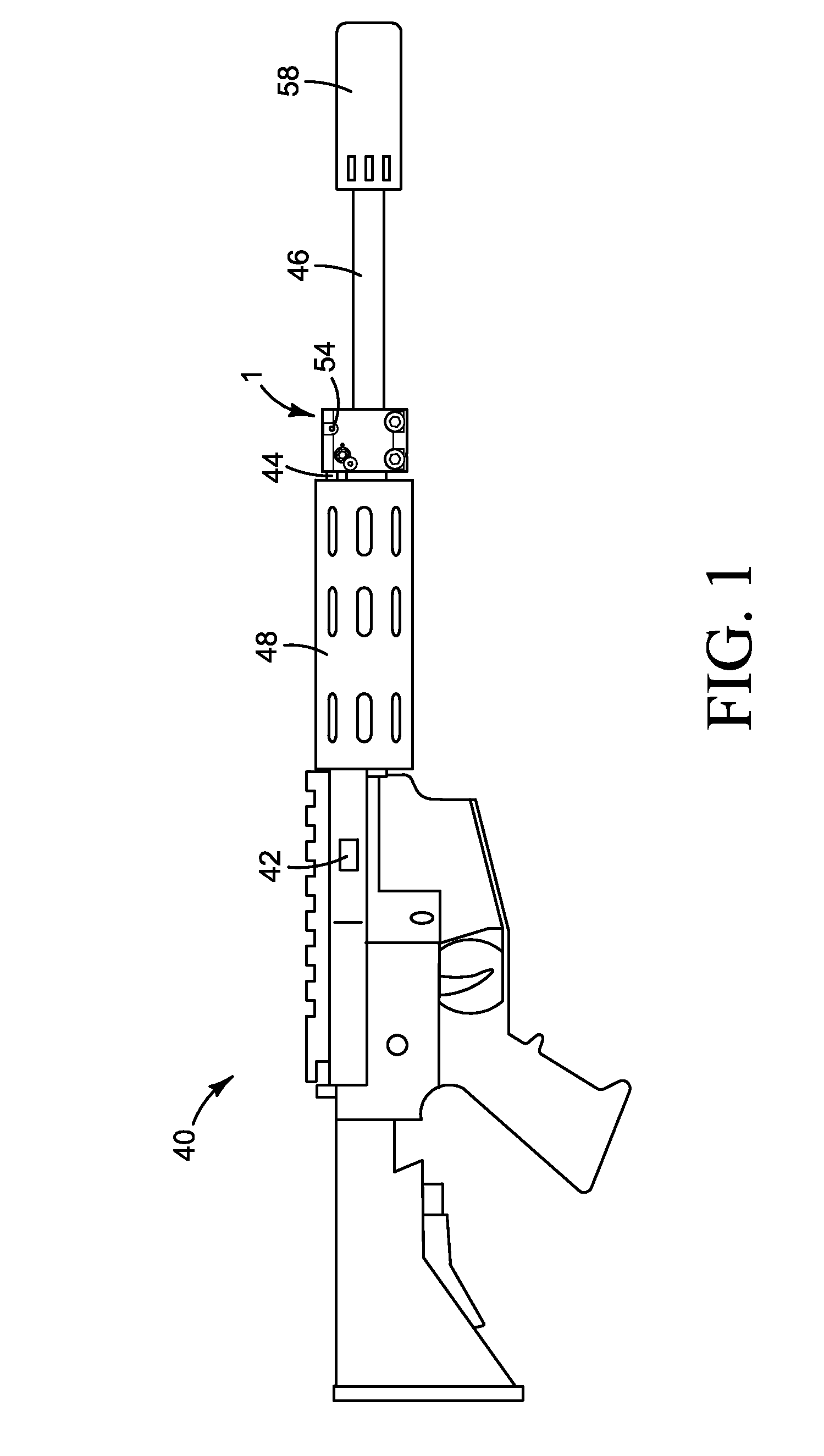

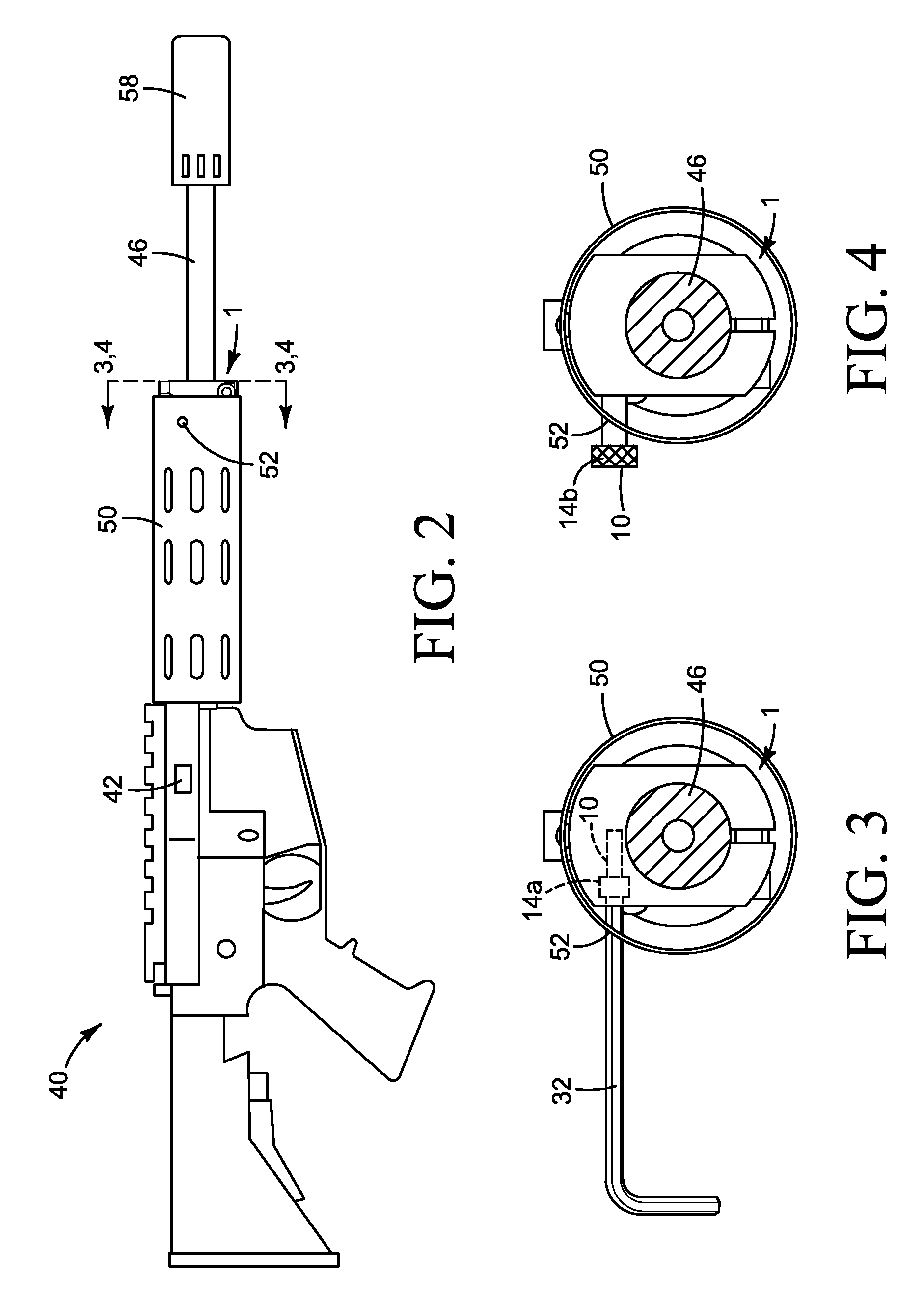

[0080]An auto-loading firearm's gas-operating system is one which utilizes a portion of the firearm cartridge's propellant gas as the energy source to operate the firearm's auto-loading mechanism. The illustrated embodiments of the invention are designed to provide users of gas-operated auto-loading firearms with a means of precisely and repeatably adjusting the amount of gas which is allowed to pass from the barrel of a host firearm into its gas-operating system, thus providing the ability to optimize the operation of a firearm by compensating for variations in ammunition loading, bullet weight, atmospheric temperature, cartridge caliber, and for the installation / removal of a silencer. The term “gas-operated auto-loading firearm” as used in this document includes, but is not limited to, direct impingement systems such as M16 / AR15 / AR10 / M4 type of firearms, as well as firearms that utilize a piston and cylinder in their gas-operating system. Please note that while the illustrated emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com