Cylinder head gasket with integrated sensor

a technology of internal combustion engine and sensor, which is applied in the direction of instruments, machines/engines, mechanical equipment, etc., can solve the problem of not being cost-effective to incorporate such sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

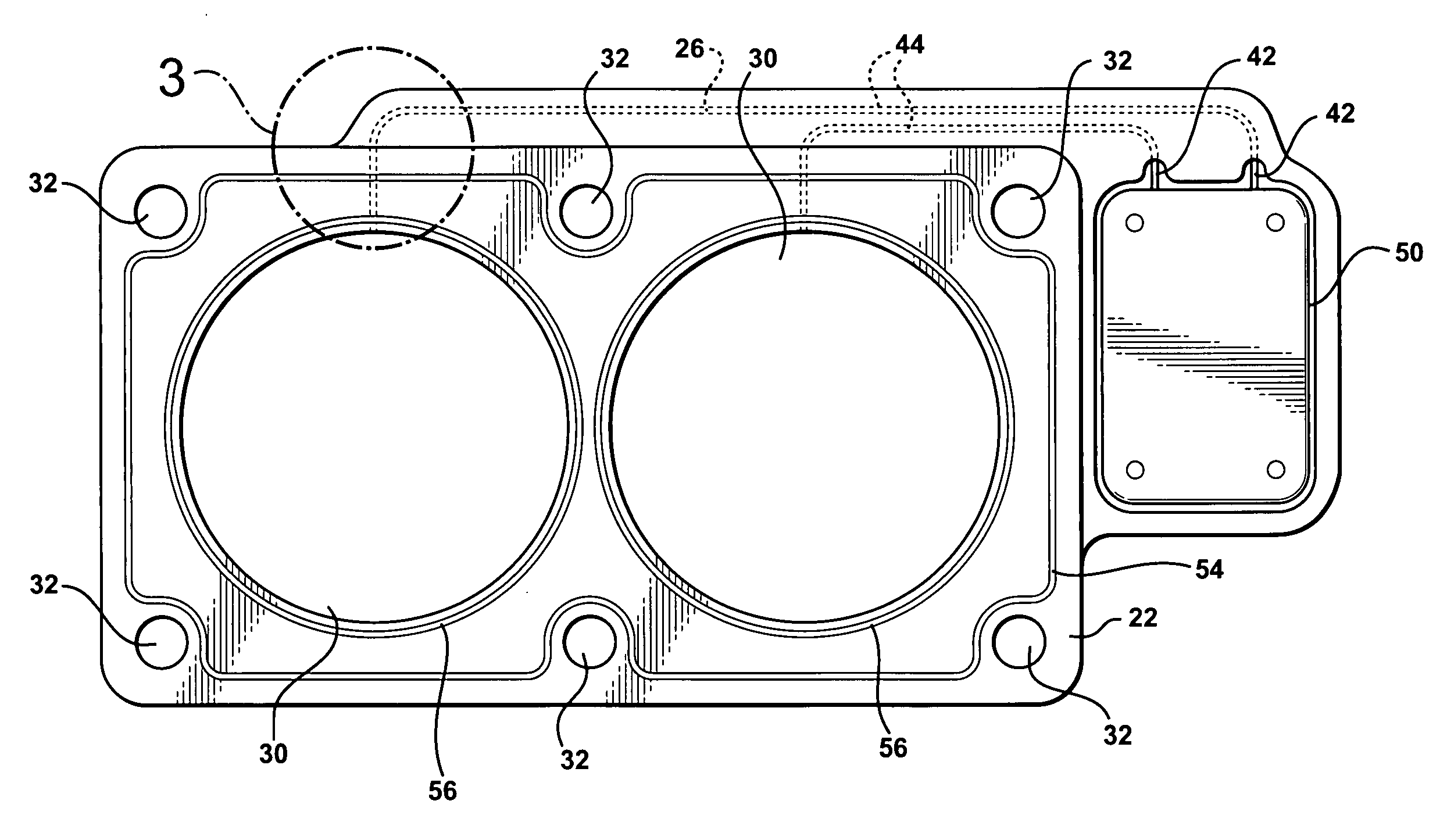

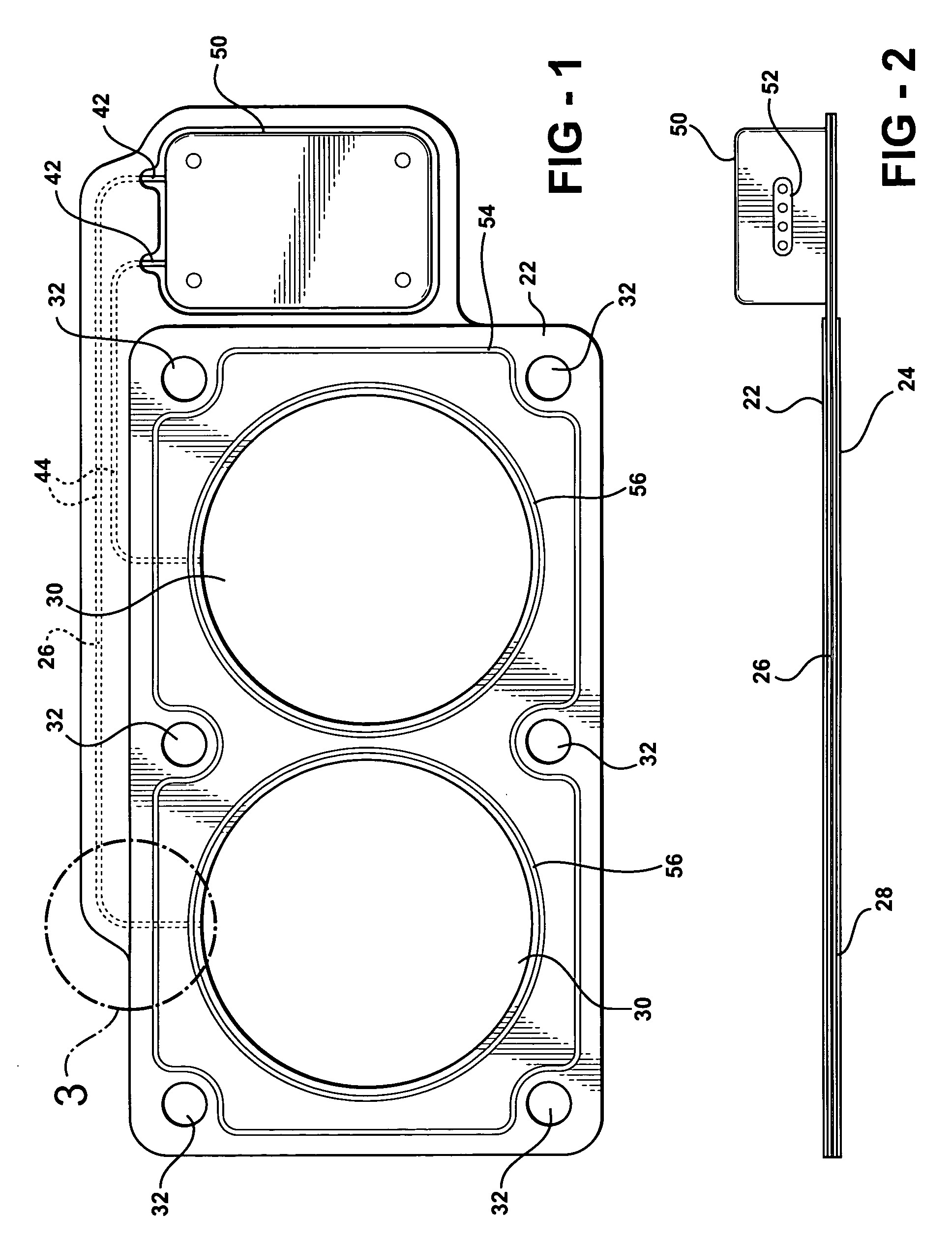

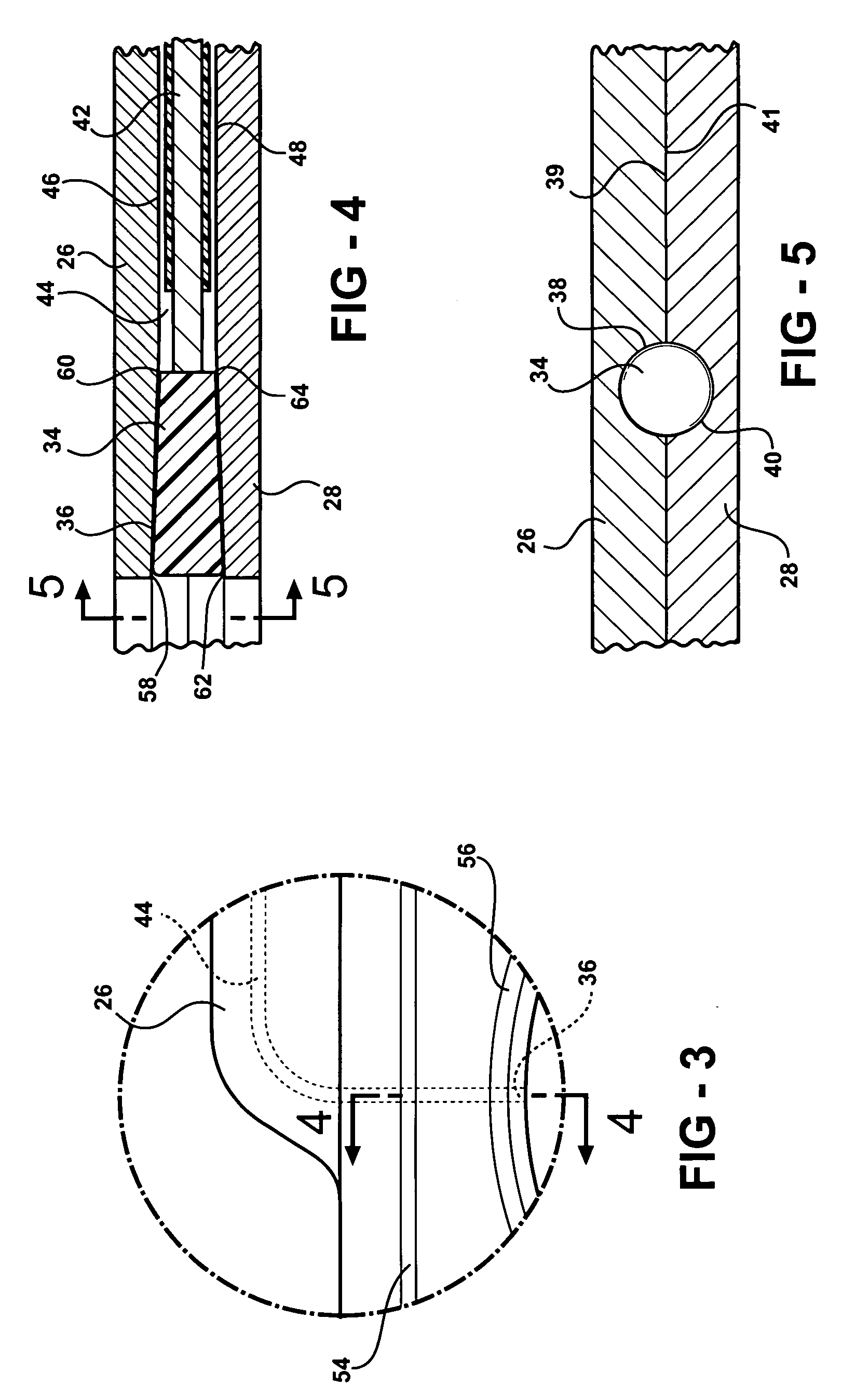

[0034] Referring to FIGS. 1-5, one embodiment of a multilayer metal gasket 20 of the present invention is illustrated. In the illustrated embodiment, gasket 20 includes upper sealing layer 22 lower sealing layer 24, first spacing layer 26 and second spacing layer 28. Gasket 20 includes at least one combustion opening 30. In the illustrated embodiment, there exist two combustion cylinder openings 30. Gasket 20 may also incorporate various other openings. The may include openings associated with various fluid passageways (not shown), such as coolant flow or intake / exhaust gas circulation passageways, bolt openings 32, as well other openings as required in conjunction with a particular cylinder block and / or head design. Gasket 20 also has integrated therein one or more sensors 34 associated with the combustion cylinder openings 30. Sensors 34 are located in sensor housings 36 formed by the mating of first sensor housing portions 38 formed on a first surface 39 of first spacing layer 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| combustion pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com