Multi-coke-oven gas-colluection-pipe pressure control apparatus and method

A gas collecting pipe pressure and gas collecting pipe technology, which is applied in the safety device of the furnace, coke oven, petroleum industry, etc., can solve the problems of large pressure influence, and achieve the effect of reducing the degree of mutual influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The basic idea of the present invention is to determine the first decoupling parameter by using the preset control parameters and the pressure values of the gas collectors, and use the predetermined coupling coefficient to determine the second opening for eliminating the coupling effect between the gas collectors The adjustment amount, and the superposition result of it and the first opening adjustment amount is used as the adjustment amount of the butterfly valve to adjust the butterfly valve.

[0055] In order for those skilled in the art to have a better understanding of the present invention, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and description.

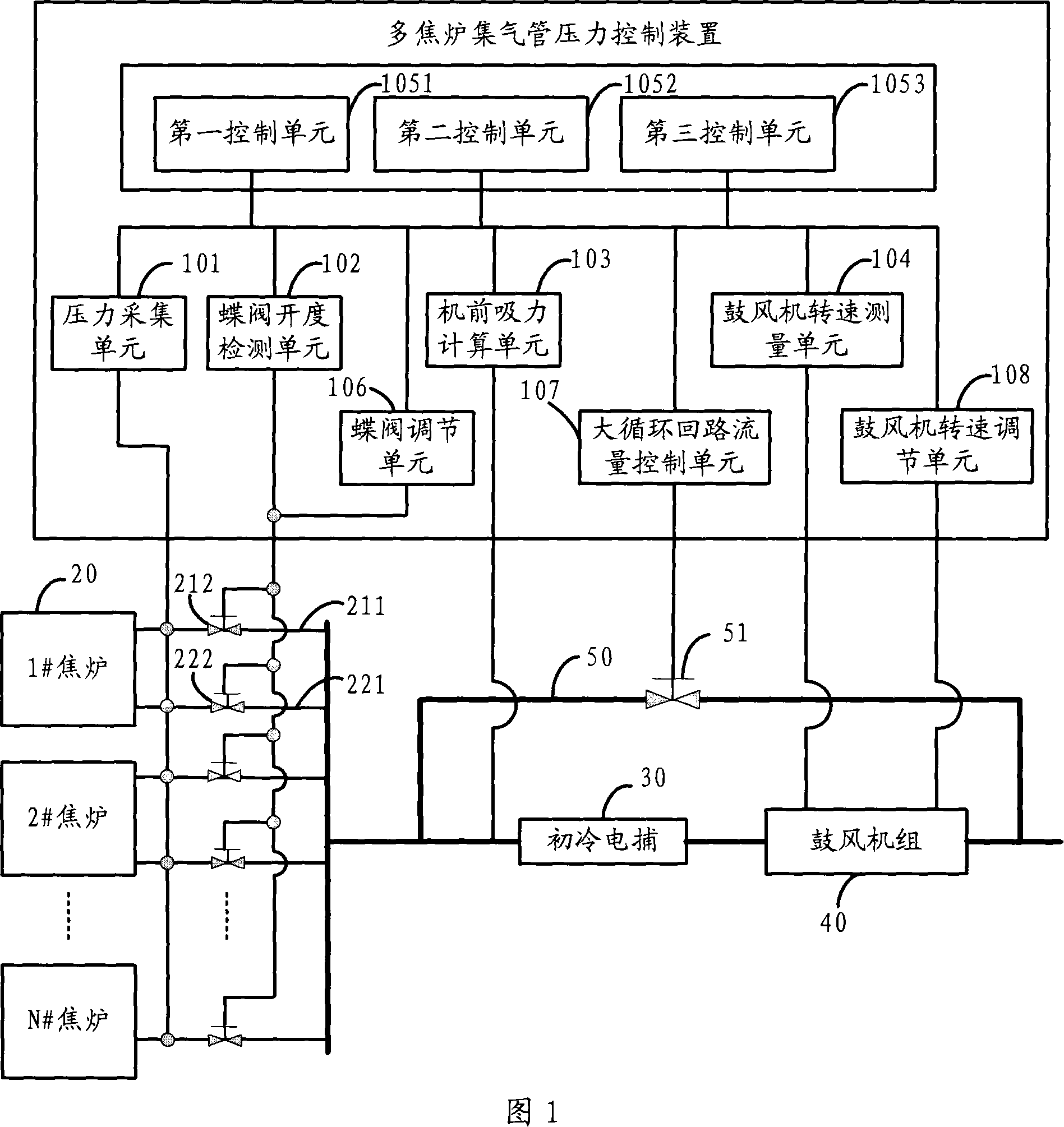

[0056] Please refer to FIG. 1 , which is a structural schematic diagram of Embodiment 1 of a multi-coke oven gas collector pressure control device according to the present invention.

[0057] A multi-coke oven gas collecting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com