Urban pipeline mobile cleaning device

A mobile cleaning device and technology for urban pipelines, which is applied in the field of urban pipeline mobile cleaning devices, can solve the problems of backward urban pipeline cleaning technology, high renovation costs, and long cleaning cycles, and achieve important economic value and social benefits. The cleaning effect is good, The effect of large injection pressure and injection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

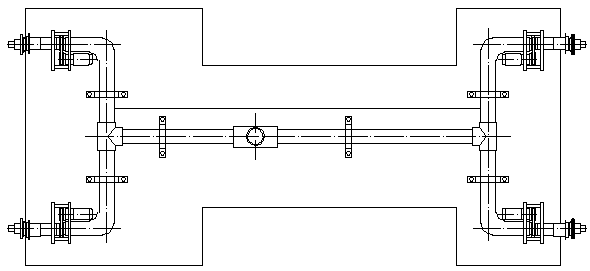

[0028] The main body of a mobile cleaning device for urban pipelines of the present invention is composed of power equipment, a high-pressure water device, a wheeled mobile trolley driven by a micro servo motor, and a post-processing device. The mobile trolley and the post-processing device are connected through pipelines.

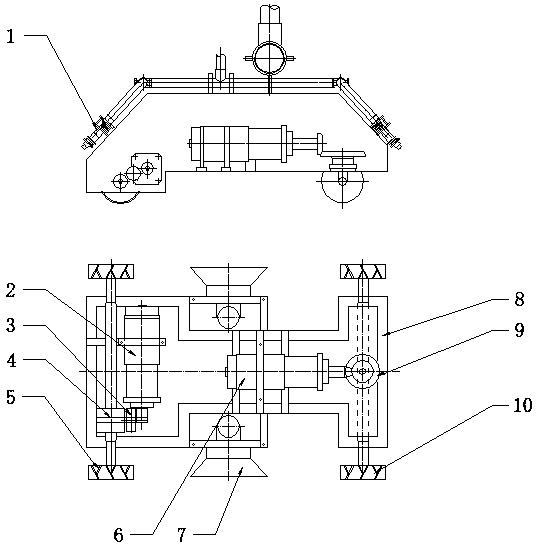

[0029] refer to figure 1 , the urban pipeline mobile cleaning device includes: a power system, a water jet system, a siphon system, a sealing system, a control system, and a take-up and release mechanism; the power system, the water jet system, the siphon system, and the take-up and release mechanism are connected to the control system, The sealing system is installed between the vehicle cover and the vehicle body of the mobile trolley, the lead-out line of the signal line and the contact point between the wheel axle and the vehicle body.

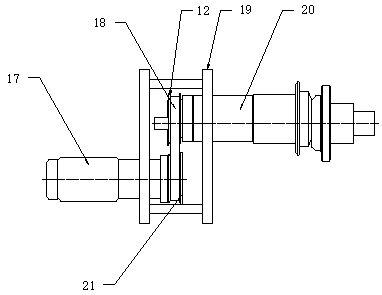

[0030] refer to figure 2 , the power system includes: a driving motor 2, a driving wheel 5, a speed reducer 3, a d...

Embodiment 2

[0042] The power equipment and high-pressure water device of the present invention can be replaced by a cleaning machine. According to the characteristics of the urban pipeline cleaned by the present invention, the cleaning pressure and flow rate, a jet-type cleaning machine can be selected, considering the requirements of high-pressure water delivery and factors such as oil resistance, corrosion resistance, and anti-static , choose fiber-reinforced resin high-pressure hose.

[0043] In the present invention, the control system controls the trolley to travel at the bottom of the pipeline according to the preset track, and during the process of traveling, the high-pressure water device delivers high-pressure water to the nozzle of the water jet system, and the formed submerged high-pressure water jet stirs up the sediment at the bottom of the pipeline Form a fluidized state, and then transport the fluid sludge to the subsequent treatment device outside the pipeline through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com