Spring tube digital compression gauge based on Hall effect

A Hall effect, spring tube technology, applied in the direction of fluid pressure measurement involving magnet displacement, can solve the problems of high price and low cost performance, and achieve the effect of no mechanical wear, high cost performance, and improved grade accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

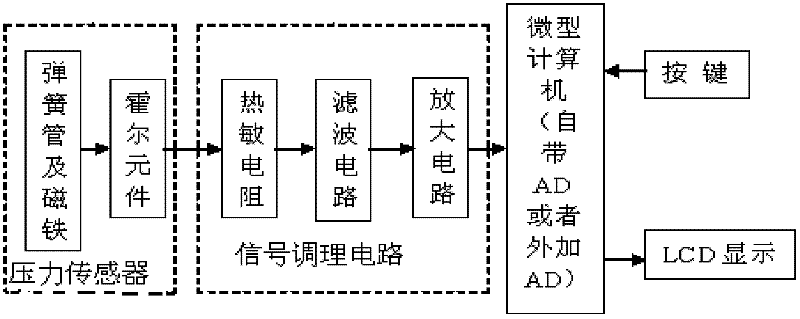

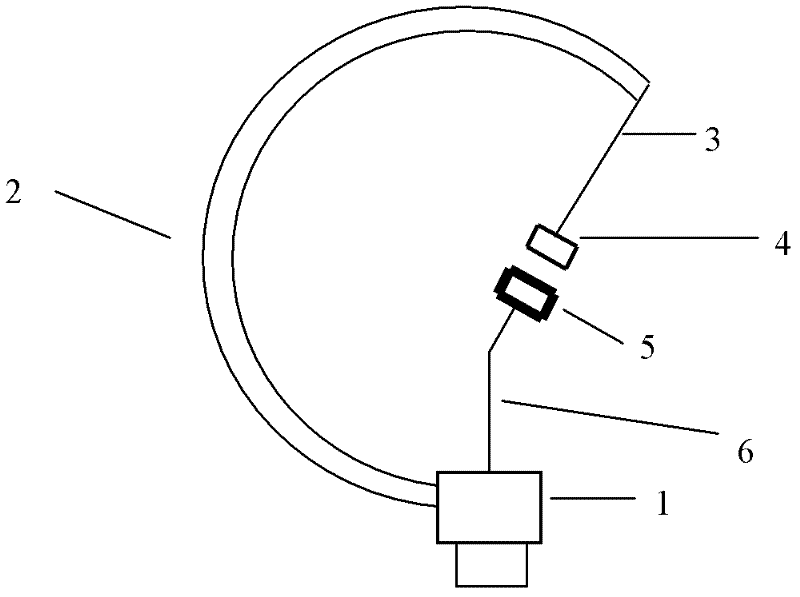

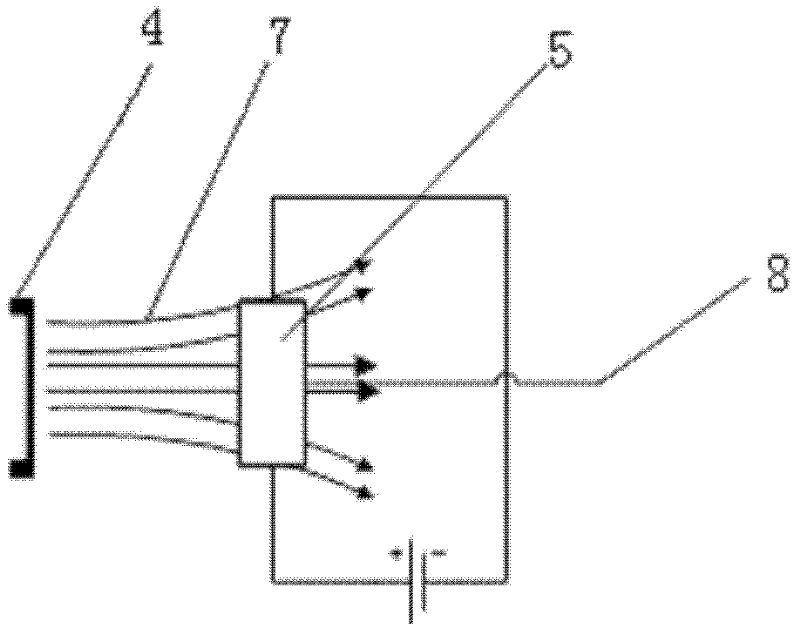

[0017] The principle diagram of a spring tube digital pressure gauge based on the Hall effect of the present invention is as follows figure 1 As shown, it includes a pressure sensing element, a signal conditioning circuit, a microcomputer, an analog-to-digital converter, a display screen, buttons, a power supply, and a connector; the pressure sensing element includes a spring tube 2, a magnet 4, and a Hall element 5 One end of the spring tube 2 is provided with a joint 1 connected to the pressure source, and the other end is closed as a free end; a magnet bracket 3 is connected to the closed end, and a magnet 4 is installed on it; the Hall element bracket is installed on the upper part of the joint 1 6. A Hall element 5 is installed on it; the sensing surface of the Hall element 5 faces and is close to the magnet 4; the output end of the Hall element is connected with the input end of the signal conditioning circuit, and the output end of the signal conditioning circuit is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com