Ionic conductive hydrogel and preparation method and application thereof

A technology of ion conduction and hydrogel, applied in the application, measurement of the property and force of applied piezoelectric resistance materials, electromagnetic measurement devices, etc., can solve the problem of low mechanical strength and elasticity, and cannot fully meet the practical application requirements of flexible electronic devices and other issues, to achieve the effect of high mechanical strength, good practical development value, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of ion conductive hydrogel, its preparation method comprises the following steps:

[0054]1) Add 4g of gelatin, 6g of acrylamide and 0.15g of aldylated β-cyclodextrin into 30mL of deionized water, then add 0.004g of N,N-methylenebisacrylamide and 8g of NaCl, Control the stirring speed to 380rpm, and stir at 60°C until the solids are completely dissolved to obtain a viscous solution;

[0055] 2) Add 0.04 g of ammonium persulfate and 40 μL of tetramethylethylenediamine into the viscous solution, then pour the viscous solution into a mold, and cure at 60° C. for 3 hours to obtain an ion-conductive hydrogel.

[0056] Performance Testing:

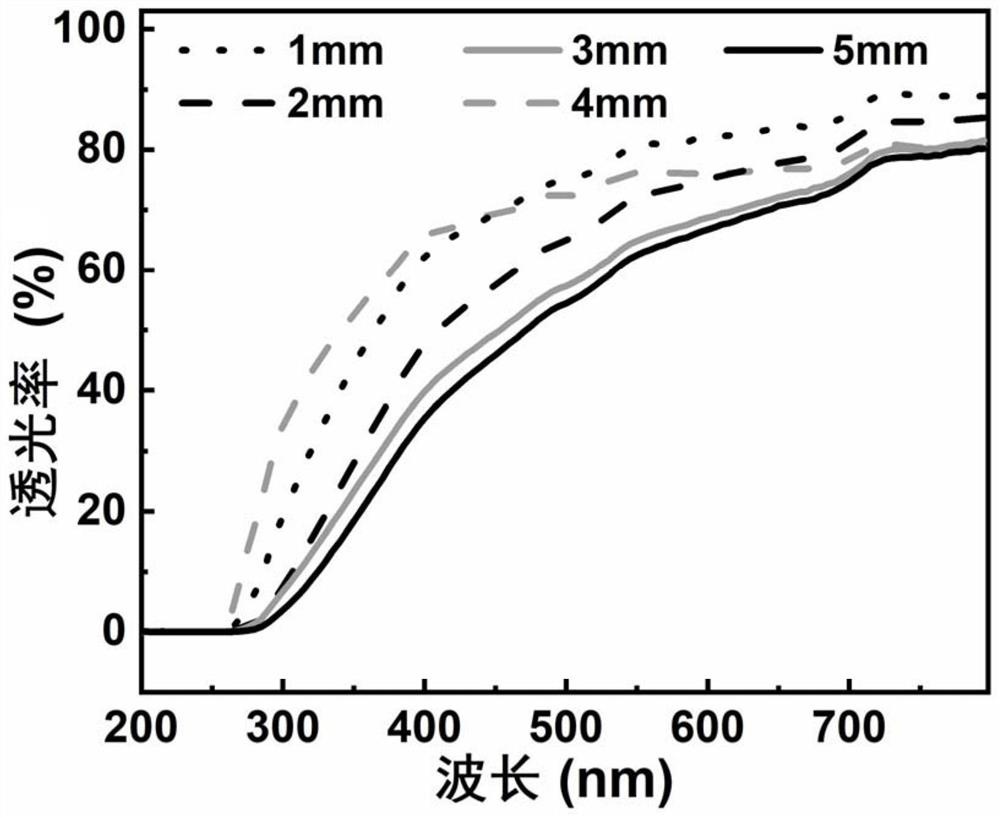

[0057] 1) The ion-conducting hydrogel prepared in Example 1 was cut into test samples with a thickness of 1mm, 2mm, 3mm, 4mm and 5mm, and a UV-ultraviolet instrument was used to test the light transmission performance. The test results were as follows: figure 1 shown.

[0058] Depend on figure 1 It can be seen that the light tr...

Embodiment 2

[0063] A kind of ion conductive hydrogel, its preparation method comprises the following steps:

[0064] 1) Add 4g of gelatin, 6g of acrylamide and 0.3g of aldylated β-cyclodextrin into 30mL of deionized water, then add 0.004g of N,N-methylenebisacrylamide and 8g of NaCl, Control the stirring speed to 380rpm, and stir at 60°C until the solids are completely dissolved to obtain a viscous solution;

[0065] 2) Add 0.04 g of ammonium persulfate and 40 μL of tetramethylethylenediamine into the viscous solution, then pour the viscous solution into a mold, and cure at 60° C. for 3 hours to obtain an ion-conductive hydrogel.

[0066] Performance test (test with reference to the method of embodiment 1):

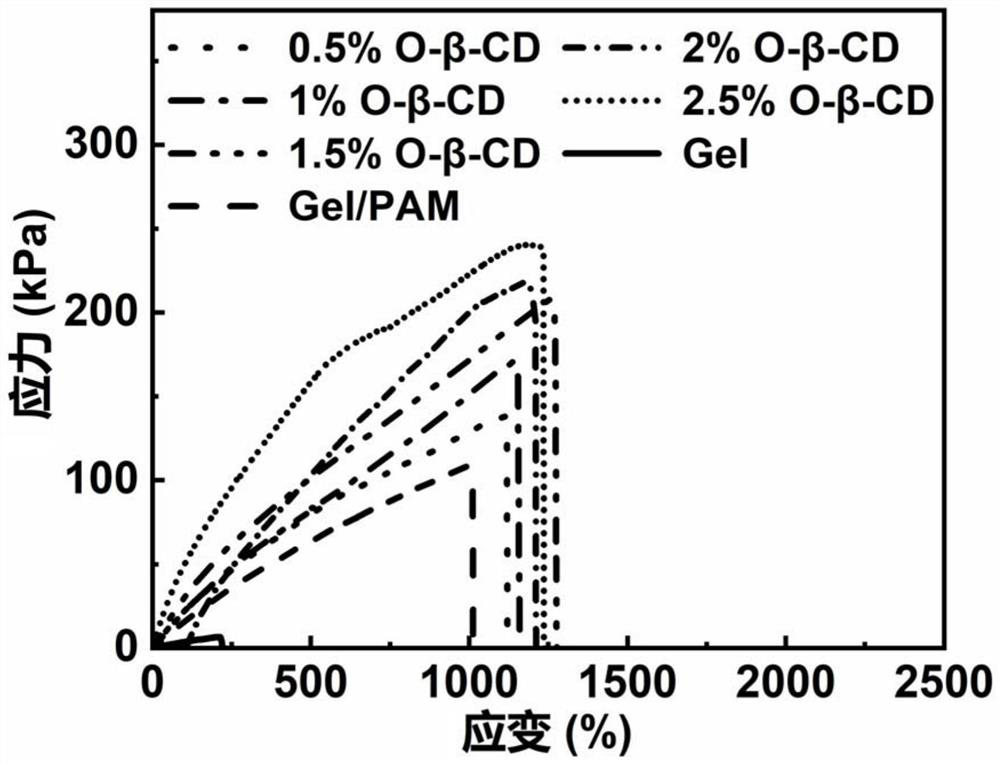

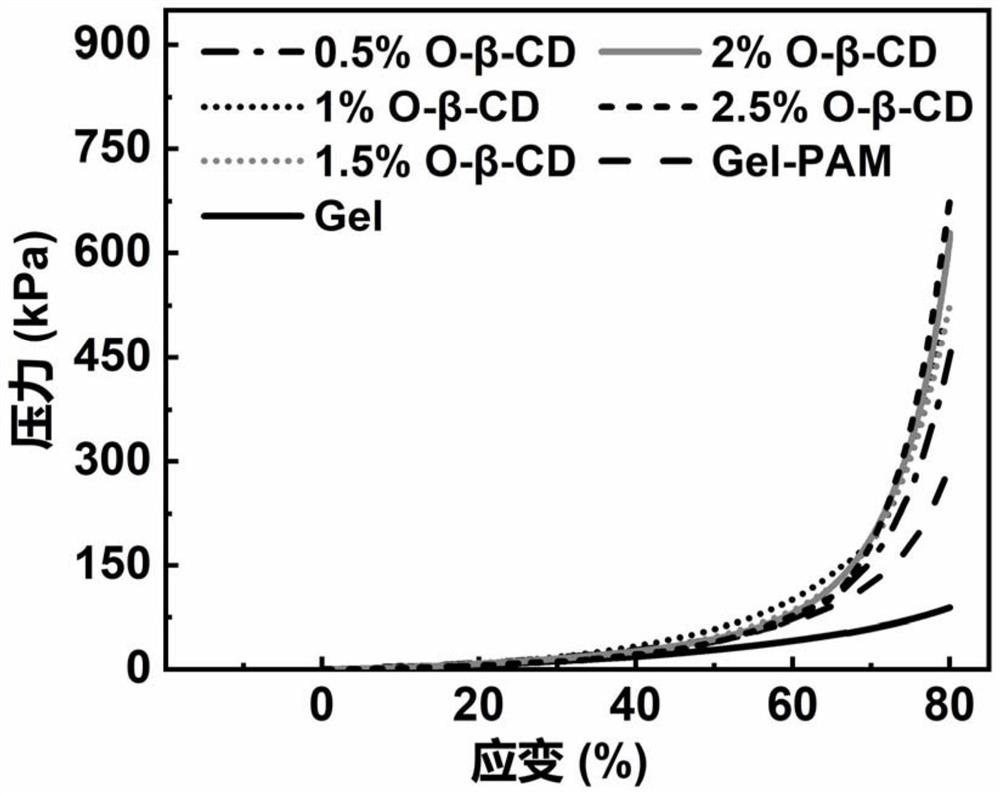

[0067] Test results: the elongation at break of the ion-conductive hydrogel of Example 2 is 1151%, the tensile strength is 172 kPa, the compressive strength is 508 kPa, and the electrical conductivity is 0.4695 S / cm.

Embodiment 3

[0069] A kind of ion conductive hydrogel, its preparation method comprises the following steps:

[0070] 1) Add 4g of gelatin, 6g of acrylamide and 0.45g of aldylated β-cyclodextrin into 30mL of deionized water, then add 0.004g of N,N-methylenebisacrylamide and 8g of NaCl, Control the stirring speed to 380rpm, and stir at 60°C until the solids are completely dissolved to obtain a viscous solution;

[0071] 2) Add 0.04 g of ammonium persulfate and 40 μL of tetramethylethylenediamine into the viscous solution, then pour the viscous solution into a mold, and cure at 60° C. for 3 hours to obtain an ion-conductive hydrogel.

[0072] Performance test (test with reference to the method of embodiment 1):

[0073] Test results: the elongation at break of the ion-conductive hydrogel of Example 3 is 1274%, the tensile strength is 209 kPa, the compressive strength is 538 kPa, and the electrical conductivity is 0.3945 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com