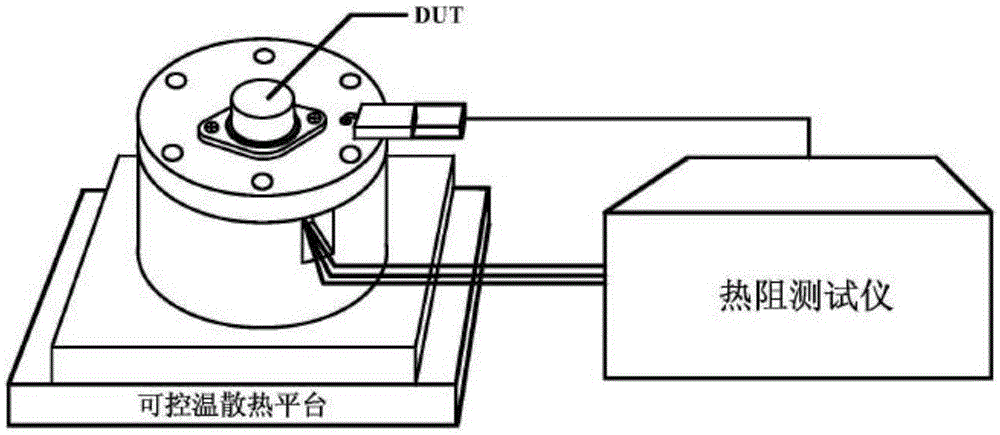

Compression-joint type power device thermal resistance testing and detecting device

A technology for testing and testing power devices, applied in the field of thermal resistance testing and testing devices for crimping power devices, which can solve the problems of low accuracy, inability to meet the requirements at the same time, and a small range of applied pressure, achieve precise and stable pressure, and reduce stress The effect of uniformity and wide pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

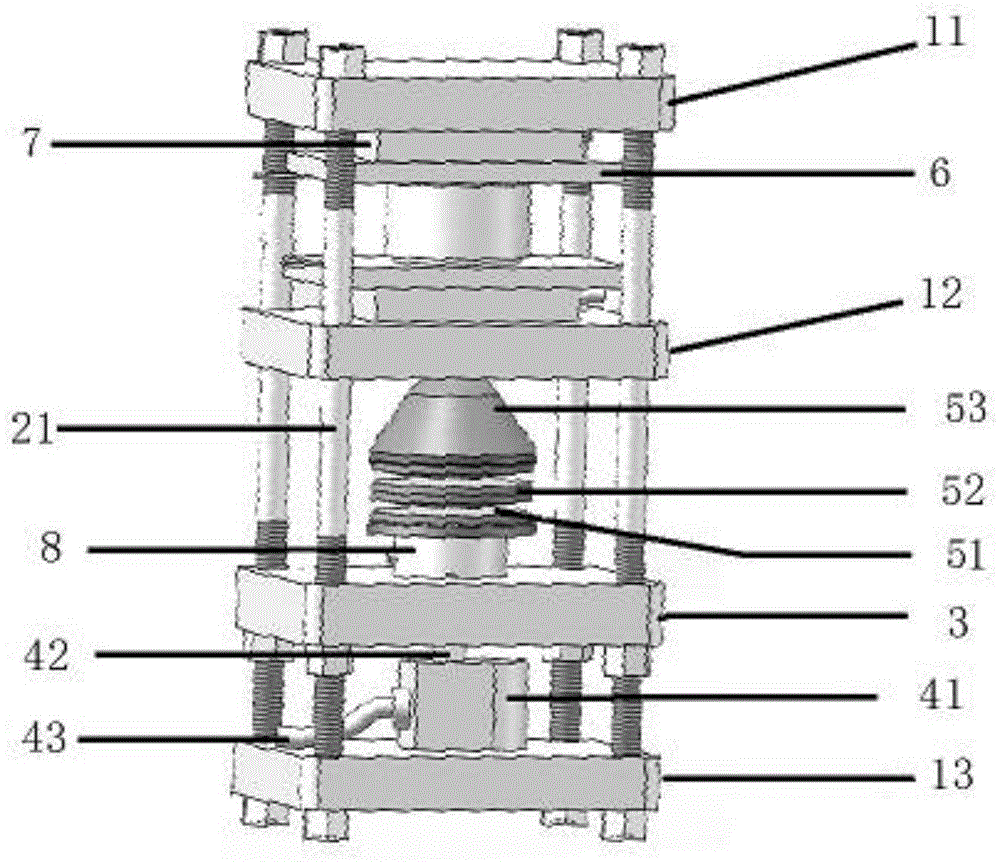

[0034] In order to better understand the present invention, the content of the present invention will be further described below with reference to the accompanying drawings and examples in the specification.

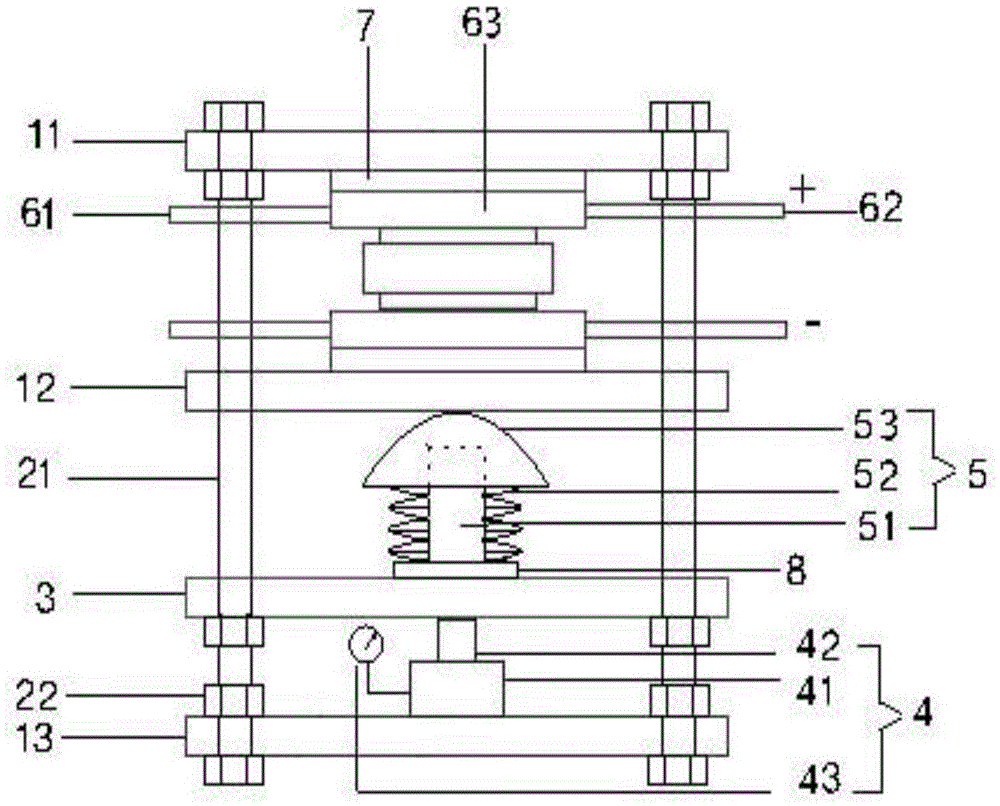

[0035] The invention provides a crimping type power device thermal resistance test and detection device, which includes a frame composed of a vertical column (21) with horizontal components arranged in a vertical direction, and the vertical column is provided with a height adjusting member and a limiting member.

[0036] The height adjusting member includes a middle base plate (12) arranged in the middle of the upright column (21) and a pressure maintaining plate (3) in the middle and lower part of the upright column (21), and the limiting member is arranged on the upright column ( 21) on the nut (22). The horizontal component includes an upper substrate (11), a middle substrate (12), a lower substrate (13) and a pressure maintaining substrate (3), and the horizontal componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com