A New Type of Radiator Thermal Resistance Flow Resistance Test Equipment

A technology for testing equipment and radiators, which is applied in the testing of mechanical components, testing of machine/structural components, and instruments. It is unfavorable for thyristor protection and other problems, and achieves the effects of simple structure, reduced water temperature fluctuation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

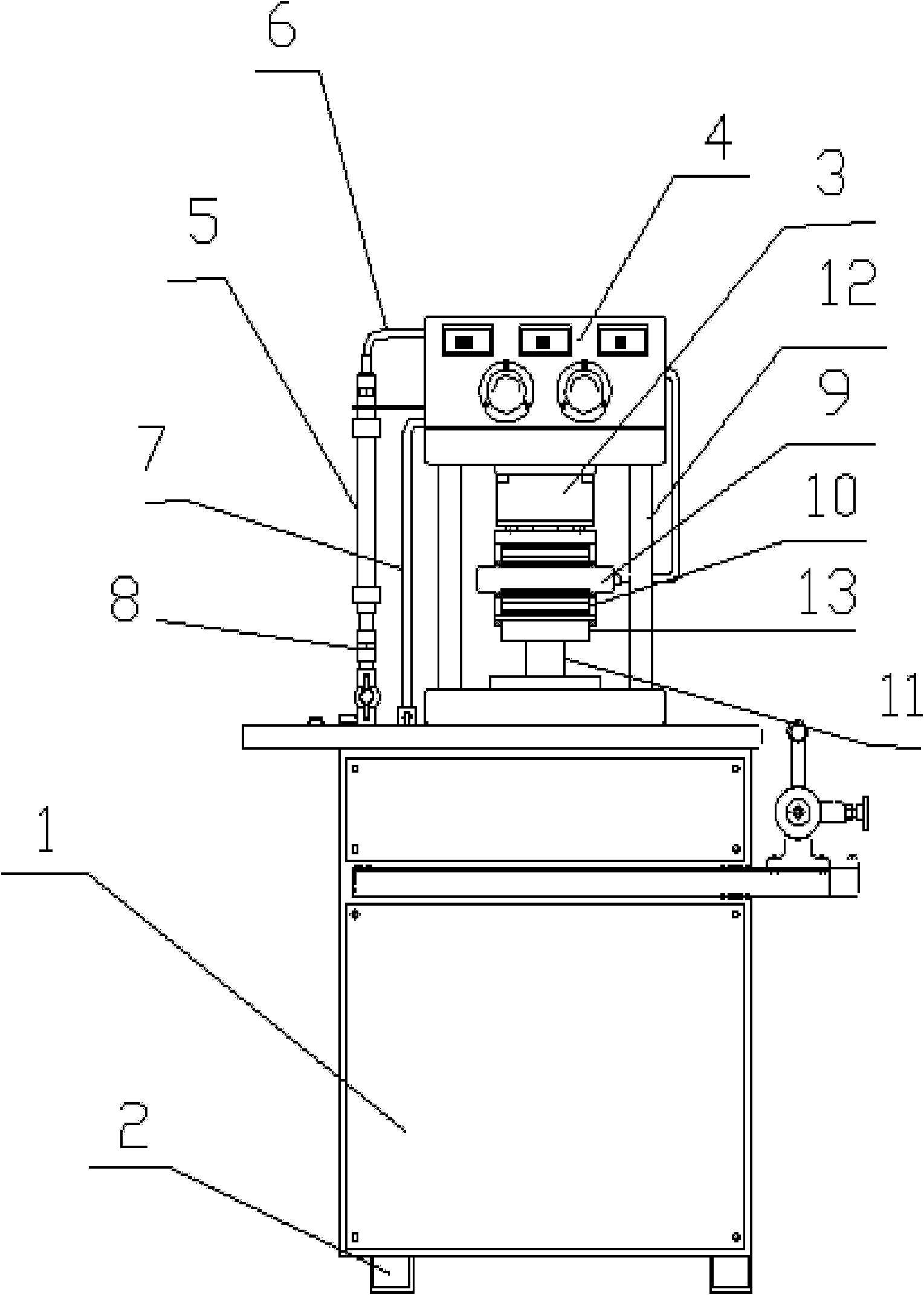

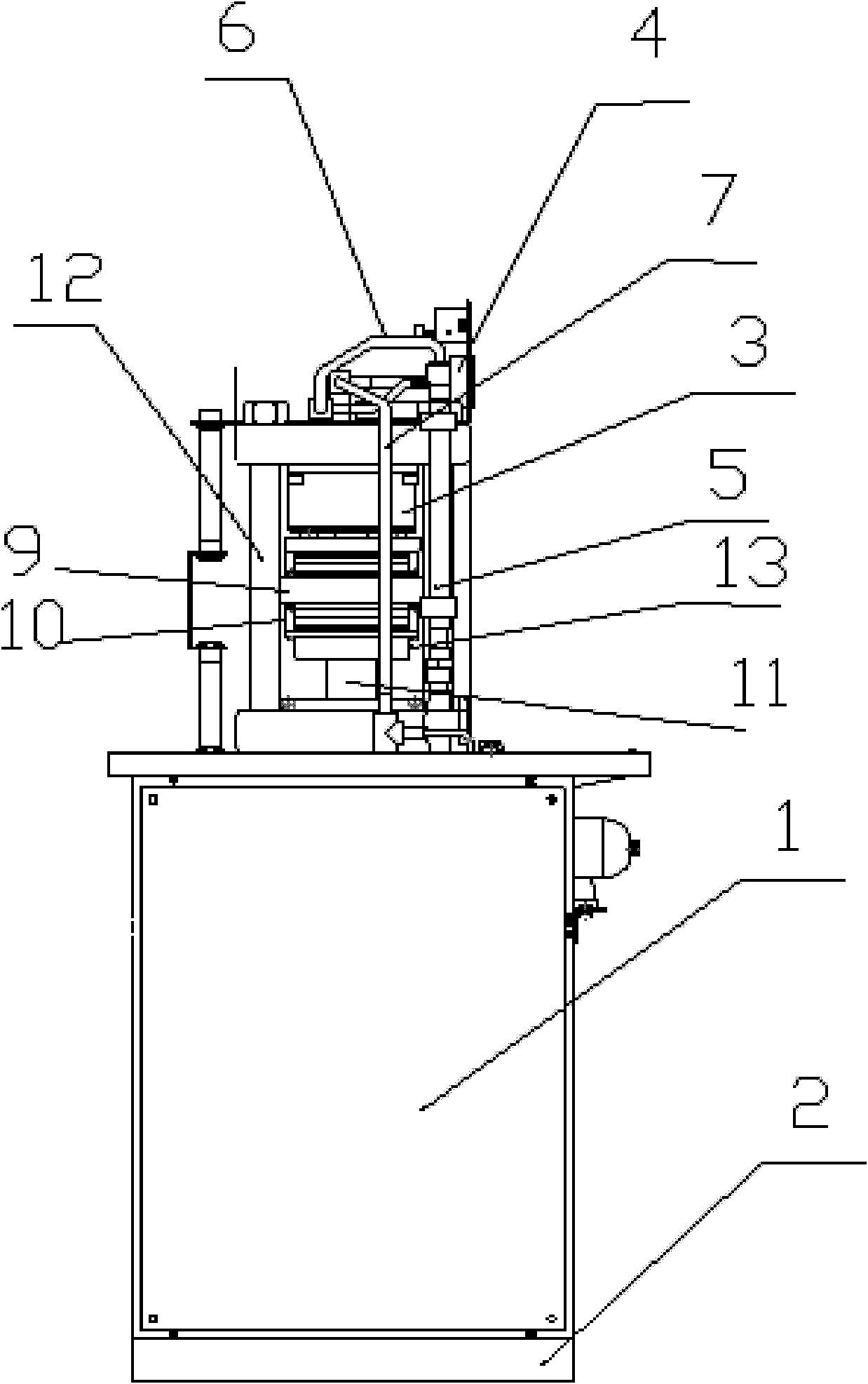

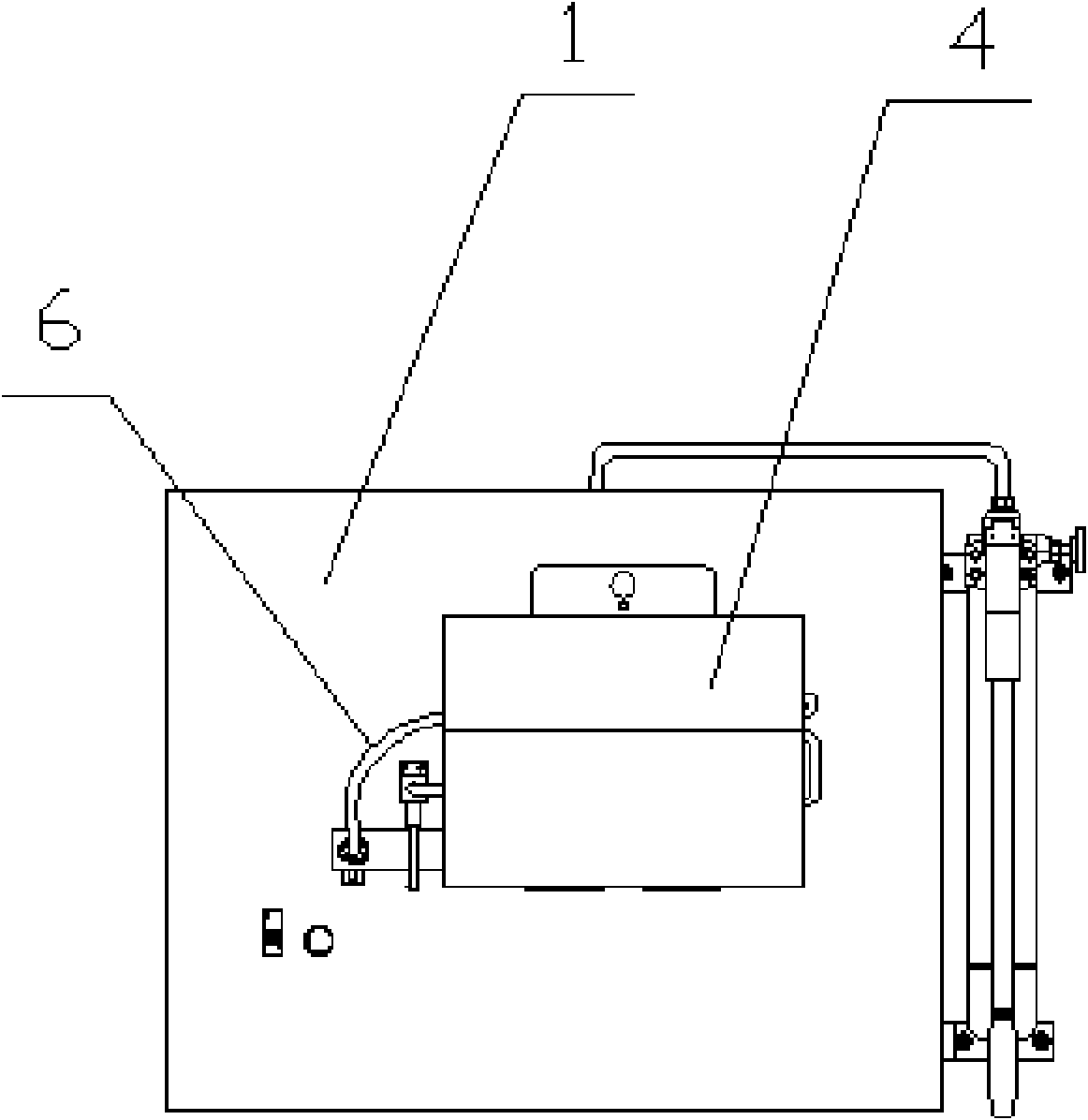

[0026] Such as Figure 1-4 As shown, the invention of this example is a new type of radiator thermal resistance flow resistance testing equipment, which includes an equipment box 1 and a base 2, and the equipment box 1 includes a thyristor radiator press-fit part 3, a water circulation system, and testing and collection equipment. 4. The equipment box 1 includes power equipment and a water storage tank; the thyristor radiator press-fit part 3 is installed on the equipment box body 1 through the fixing frame 12, and one end of the thyristor radiator press-fit part 3 is connected to the equipment box body 1, The other end is connected with the test and collection equipment 4, and the test and collection equipment 4 is connected with the reservoir through a water circulation system, and a water circulation system is provided between the thyristor radiator pressing part 3 and the test and collection equipment 4; the thyristor radiator The press-fit part 3 includes a hydraulic mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com