Resistor-type pressure sensor and making method thereof

A resistive pressure and sensor technology, applied in the electronic field, can solve the problems of enhancing the pressure range of high sensitivity of the pressure sensor and the small pressure range of the elastic sensitive layer, and achieve the effects of enhancing the sensitivity, reducing the cost and lowering the price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

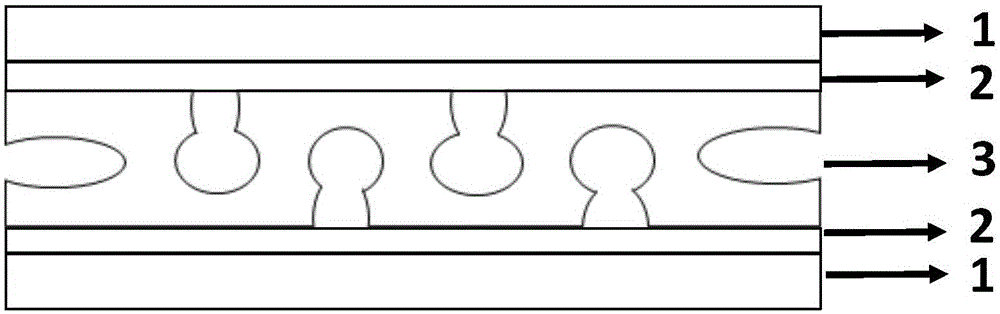

[0034] The preparation method of the resistive pressure sensor of the present invention comprises the following steps:

[0035] 1) ultrasonically cleaning the substrate 1 with ethanol solution, acetone solution and deionized water, drying after cleaning, and treating the surface of the substrate with oxygen plasma or ultraviolet light / ozone;

[0036] 2) Prepare the electrode 2 on the substrate 1 by means of vacuum evaporation, magnetron sputtering, spin coating, spray coating, doctor blade coating or gravure printing;

[0037] 3) Weigh the thermosetting elastic material, foaming material and conductive material respectively, mix and stir them evenly, wherein the mixing ratio of the thermosetting elastic material and foaming material is between 10:1-10:3 , the mixing ratio of the thermosetting elastic material and the conductive material is between 20:1-5:2;

[0038] 4) Place the PET film on a flat bottom plate, set gaskets of the same height on both sides of the PET film, and...

Embodiment 1

[0045] Complete the preparation of the resistive pressure sensor through the following specific steps:

[0046] (1) Utilize ethanol solution, acetone solution and deionized water to carry out ultrasonic cleaning on the ethylene terephthalate (PET) substrate, dry after cleaning, and use oxygen plasma or ultraviolet light / ozone to treat the substrate surface;

[0047] (2) Prepare silver nanowire electrodes on the substrate 1 by spin coating;

[0048] (3) Get thermosetting elastic material polydimethylsiloxane (PDMS), powdery foaming material ammonium bicarbonate and carbon black, mix the three and stir evenly, described polydimethylsiloxane, The mass ratio of ammonium bicarbonate and carbon black is 10:1:0.5;

[0049] (4) The PET film is placed on a flat base plate, and gaskets of consistent height are arranged on both sides of the PET film, and the uniformly mixed cured elastic material, foaming material and conductive material are poured on the PET film;

[0050] (5) Cover a...

Embodiment 2

[0055] Complete the preparation of the resistive pressure sensor through the following specific steps:

[0056] (1) Utilize ethanol solution, acetone solution and deionized water to clean the flexible transparent substrate 1 of polyethylene naphthalate (PEN), blow dry with dry nitrogen after cleaning, and adopt oxygen plasma or ultraviolet light / Ozone treated substrate surface

[0057] (2) preparing a single-walled carbon nanotube electrode on the substrate 1 by spin coating;

[0058] (3) Get thermosetting elastic material platinum catalyzed silica gel (Ecoflex), powdery foaming material sodium bicarbonate and graphene, mix the three and stir evenly, described polydimethylsiloxane, ammonium bicarbonate and The mass ratio of graphene is 5:1:0.5;

[0059] (4) The PET film is placed on a flat base plate, and gaskets of consistent height are arranged on both sides of the PET film, and the uniformly mixed cured elastic material, foaming material and conductive material are poure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com