Method for utilizing pressure energy of natural gas

A technology of natural gas and pressure energy, applied in compressors, lighting and heating equipment, indirect heat exchangers, etc., can solve problems such as instances where cold energy is not fully utilized, improve energy utilization efficiency, facilitate technology, eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

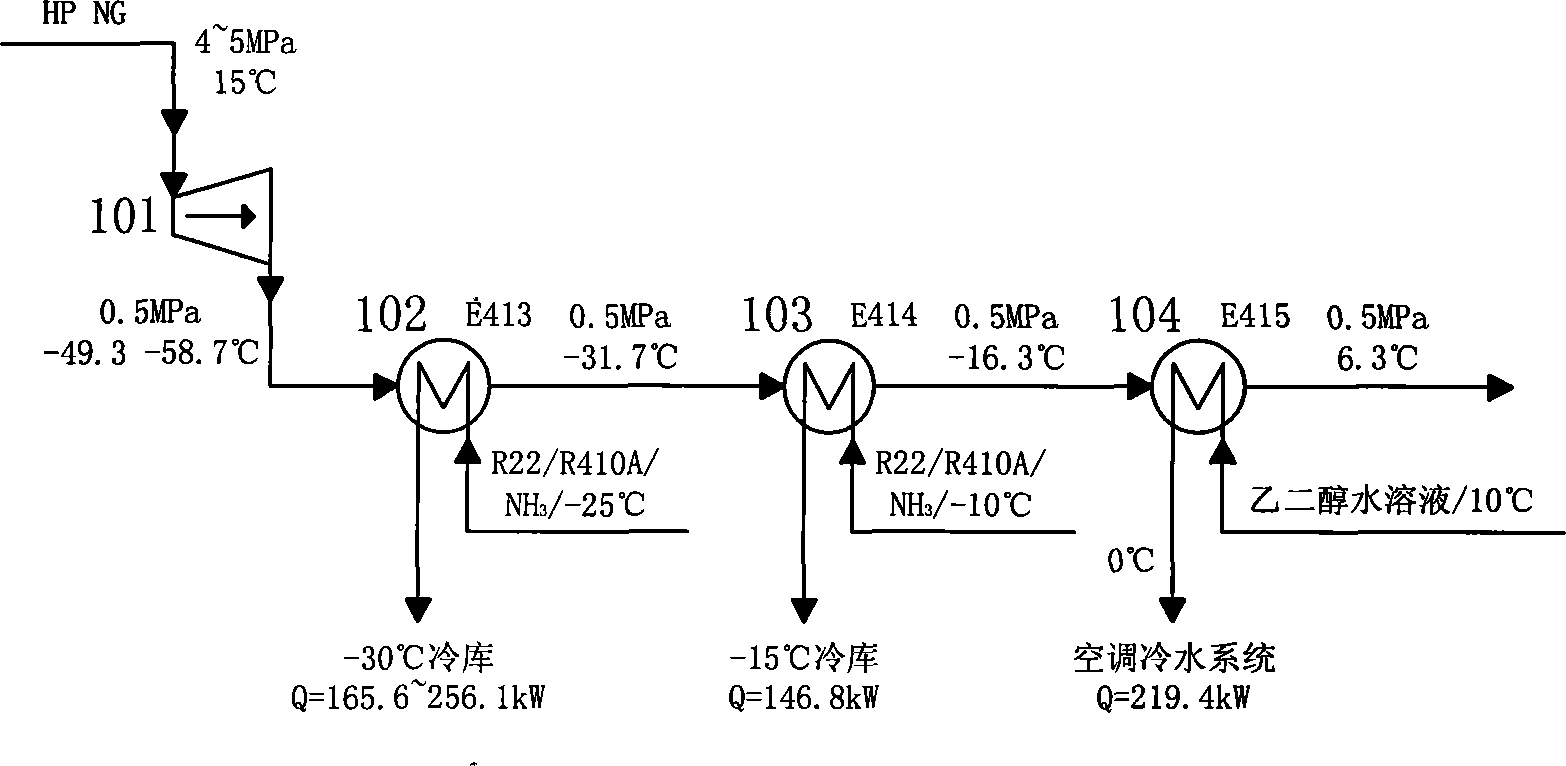

[0047] Such as figure 1Shown is a process flow for converting the pressure energy of natural gas into cold energy by using an unpowered refrigerator and using it for users of cold energy at different temperature levels.

[0048] High-pressure natural gas (pressure about 4.0~5.0MPa) and temperature about 15°C is expanded and decompressed to 0.5MPa by the unpowered refrigerator 101, and the temperature drops to -49.3°C~-58.7°C, becoming low-temperature natural gas. In order to recover the cold energy of natural gas for refrigeration in -30°C cold storage, the refrigerant in the cold storage (such as R22, R410A, ammonia, etc.) exchanges heat with low-temperature natural gas in E413 equipment 102, and the refrigerant absorbs cold energy and liquefies, and then The brine pump is transported to the cold storage to evaporate and release cold energy. In order to make full use of the cold energy of low-temperature natural gas, two cold storages with different evaporation temperatures ...

Embodiment 2

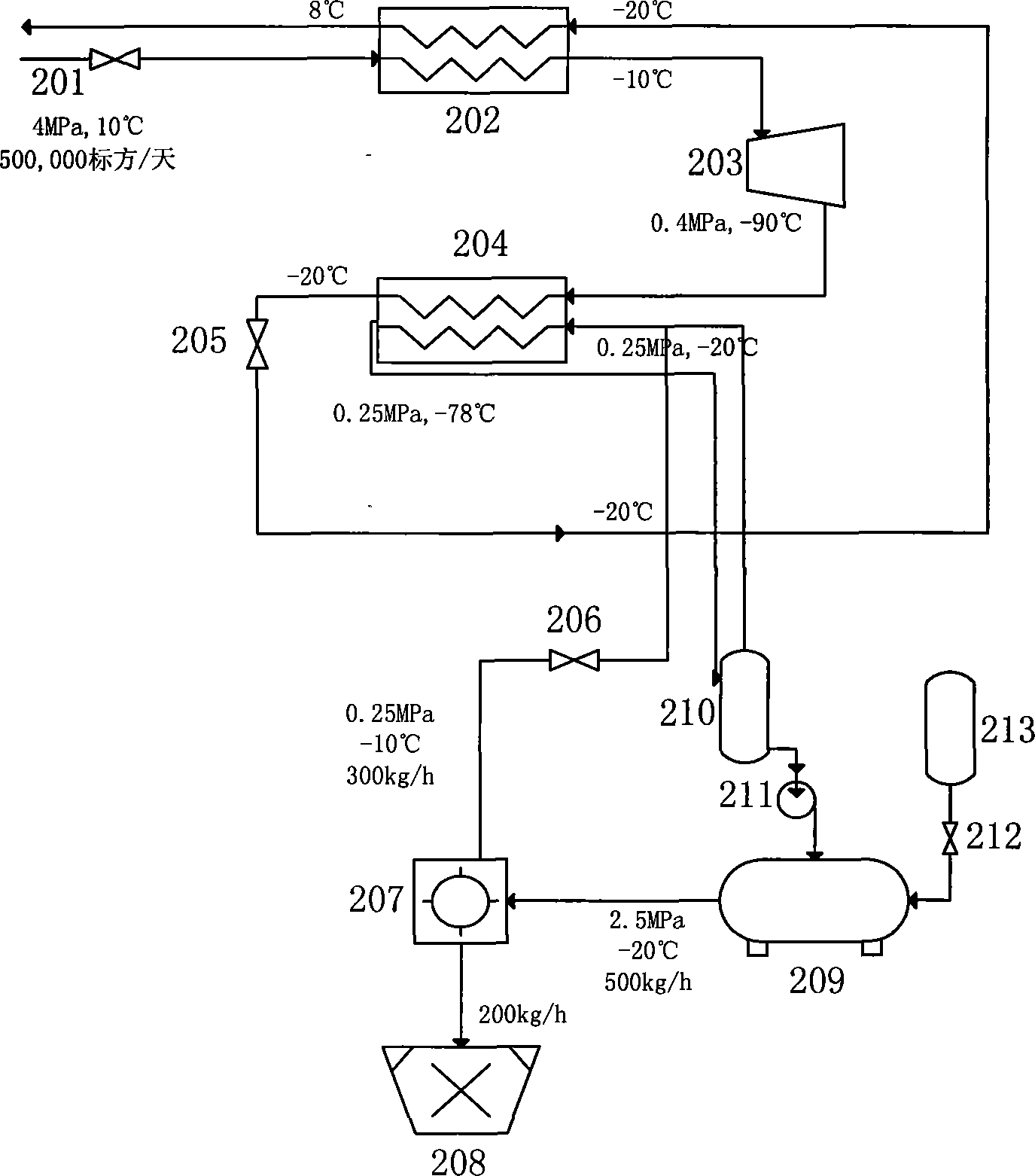

[0057] Embodiment 2 (natural gas pressure energy refrigeration is used for dry ice production)

[0058] Dry ice is a solid substance obtained by compressing, purifying, liquefying, and decompressing carbon dioxide gas. The traditional process is to compress the carbon dioxide gas to 2.5-3.0MPa, and then use refrigeration equipment to cool and liquefy it. By using the cold energy of natural gas expansion and refrigeration, it is easy to obtain the low temperature required for cooling and liquefying carbon dioxide, thereby reducing the working pressure of the liquefaction device to about 0.9MPa. Compared with the traditional process, the load of refrigeration equipment is greatly reduced, and the power consumption is also greatly reduced.

[0059] Take Tianxin Natural Gas Pressure Regulating Station in Guangzhou City as an example. The pressure of natural gas received by the pressure regulating station is 3.6-5.2 MPa, the gas source is LNG imported from Australia, and the maxi...

Embodiment 3

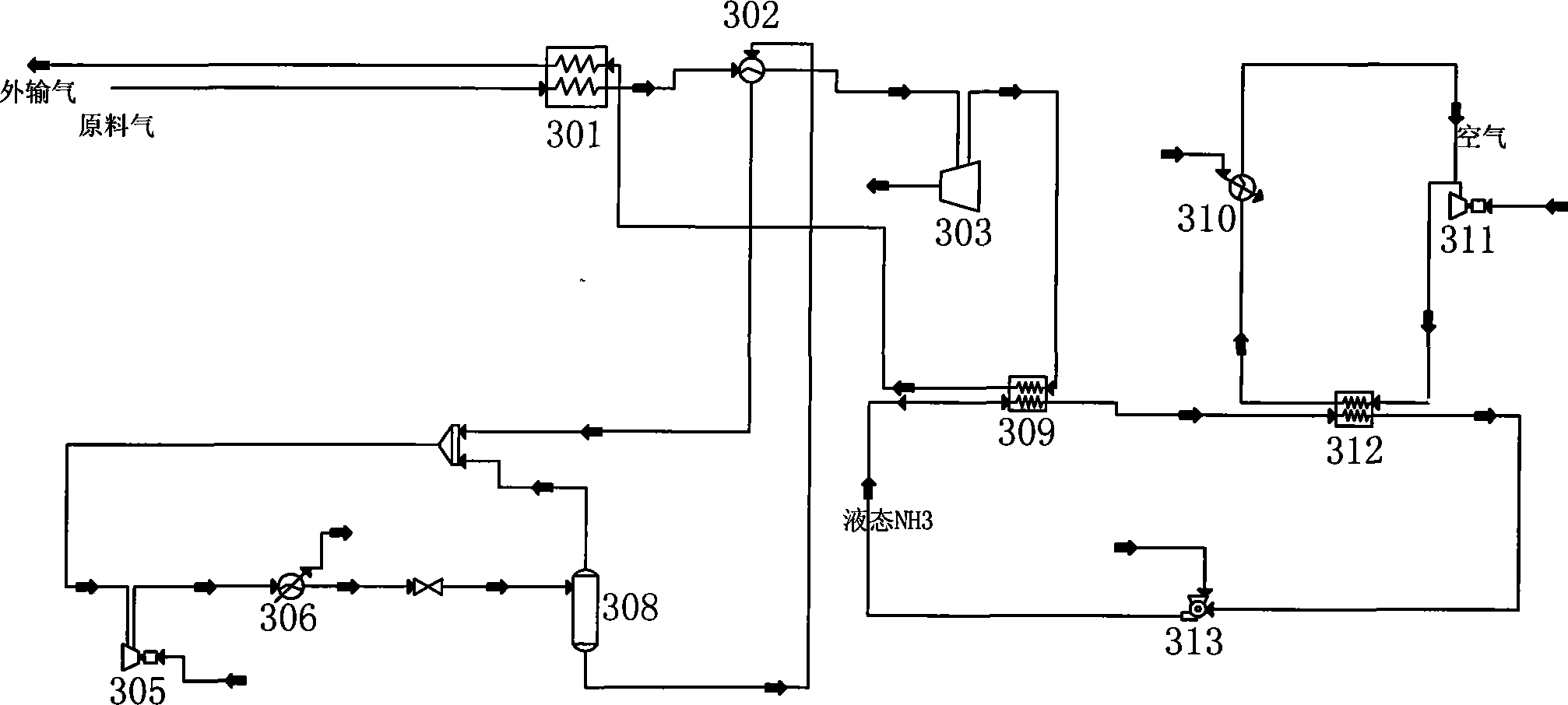

[0061] Embodiment 3 (natural gas pressure energy refrigeration is used for cold storage production)

[0062] The temperature of the freezer is usually around -20°C to -30°C; the freezer is used for short-term or long-term storage of cooled and frozen foods at different temperatures in refrigerators and freezers at different temperatures. Basically, multi-stage electric compression refrigeration devices are used to maintain the low temperature of the cold storage. Using the cheap cold energy recovered from high-pressure natural gas instead of electric refrigeration as the cold source of the cold storage can reduce the investment in the compression refrigeration system and generate greater economic benefits.

[0063] High-pressure natural gas (about 5.0 MPa) enters the primary precooler 301, and then enters the ammonia evaporator 302 for secondary heat exchange. The pressure is reduced to about 0.4 MPa in the expansion device 303, and the gas temperature is reduced to -100°C. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com