Patents

Literature

56results about How to "Practical technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

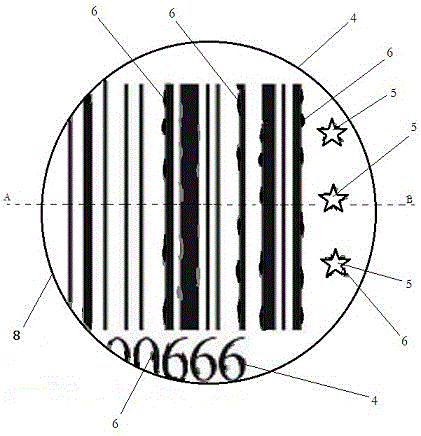

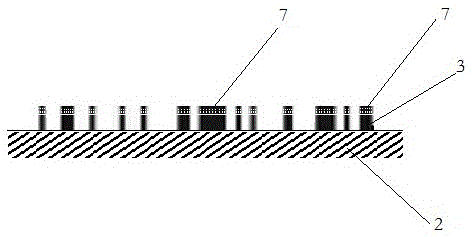

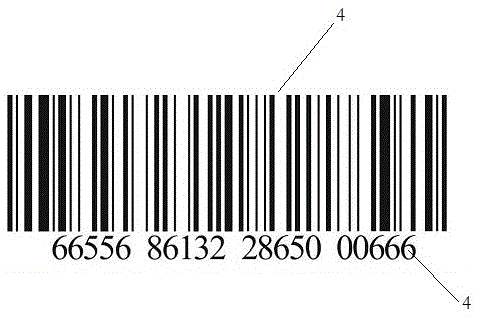

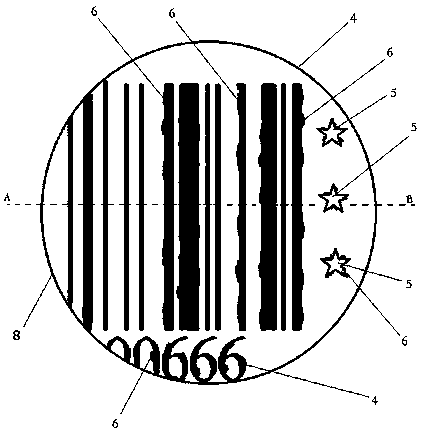

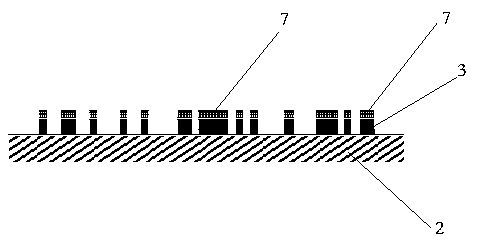

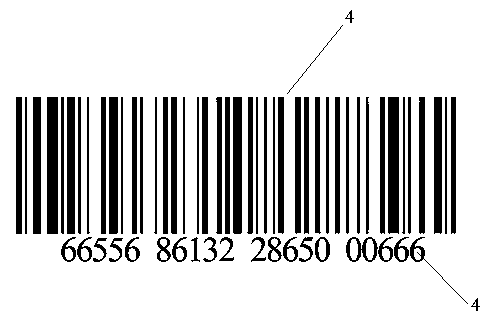

Anti-counterfeiting method of mobile phone identification code sawtooth

ActiveCN104794629BNo additional printing costsEasy to identifyCharacter printing data arrangement from carrierSpecial data processing applicationsComputer scienceMobile phone

The invention provides an anti-counterfeiting method by utilizing an intelligent mobile phone to identify code saw-teeth. The method comprises the steps of amplifying and photographing saw-teeth of a product code and image-text margin; storing the photographed saw-tooth characteristic information into an anti-counterfeiting system database to be used as anti-counterfeiting characteristic filing information. The method is simple and easy to implement, and for the user product of the existing drug electronic supervision code, the amplified picture of the saw-teeth is stored when the product is under the automatic quality inspection and is used as the anti-counterfeiting characteristic filing information to be stored. By implementing the method, the equipment investment is not increased, the procedure is not increased, the cost is not increased, an effective anti-counterfeiting function of the product can be realized, and the bug of the digital anti-counterfeiting technology such as the telegram code anti-counterfeiting technology can be blocked up.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

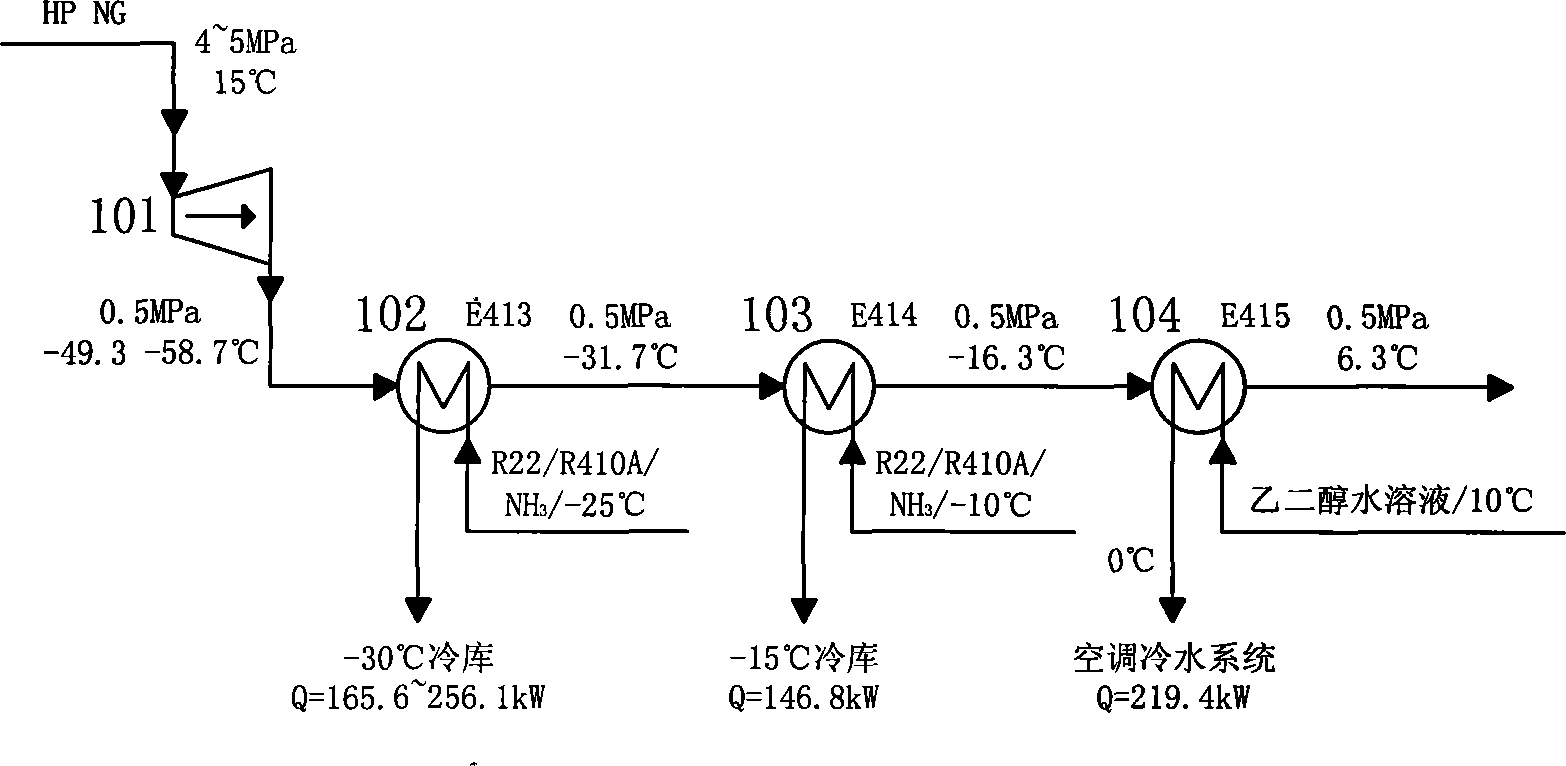

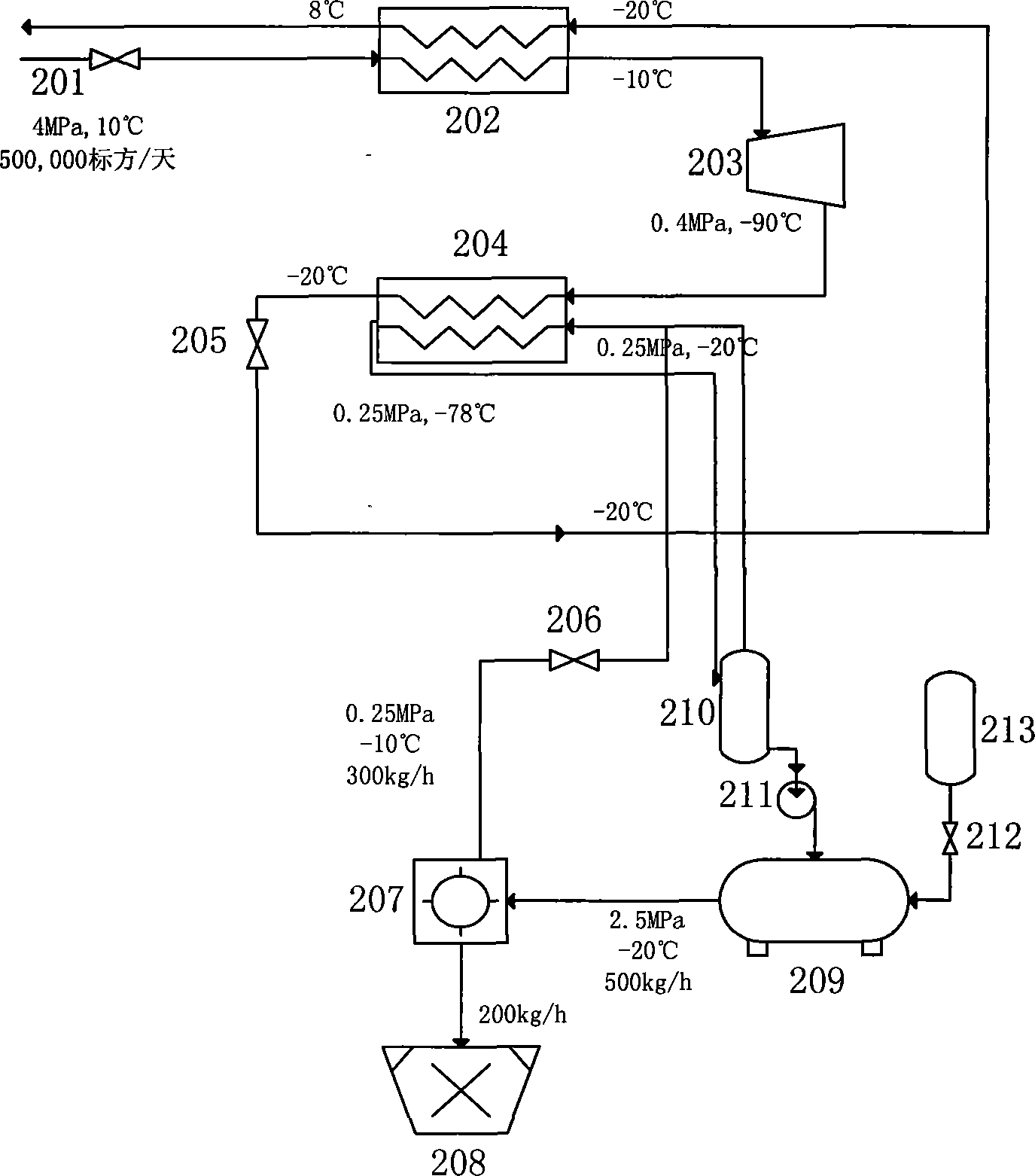

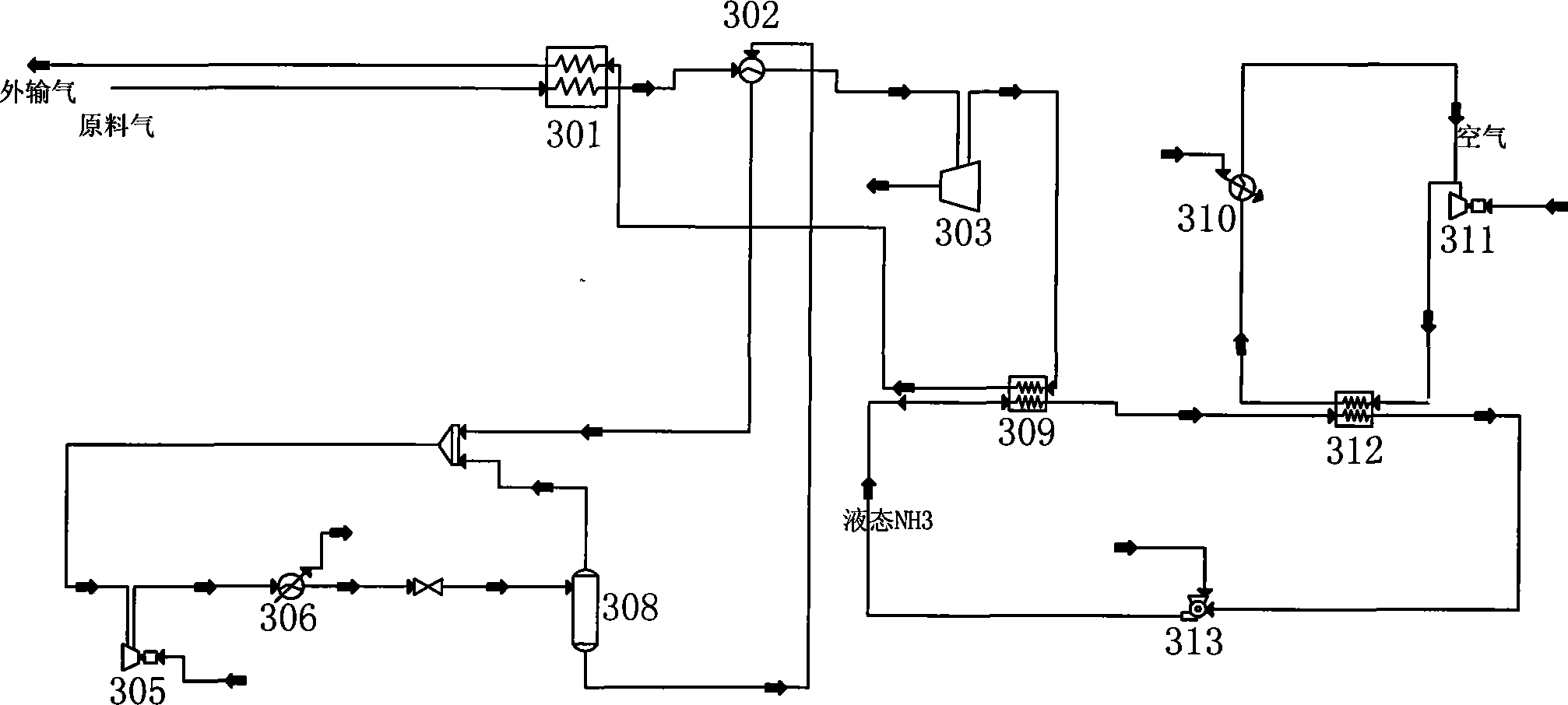

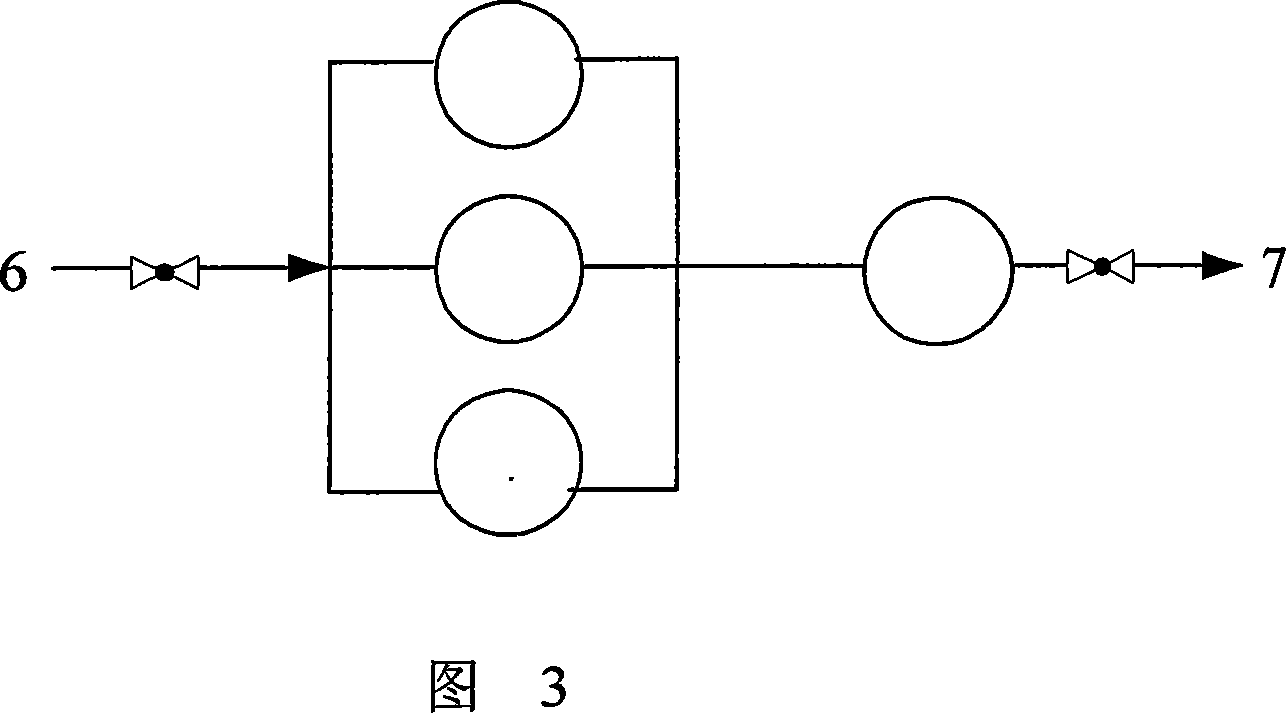

Method for utilizing pressure energy of natural gas

InactiveCN101245956AImprove utilization efficiencySimple processing technologyCompression machinesStationary plate conduit assembliesWaste rubberEngineering

The invention discloses a method which utilizes natural gas pressure energy; namely, the pressure and the temperature of the natural gas in a high pressure pipeline are reduced by a no-power refrigerator so as to gain low temperature natural gas which then exchanges the heat with a normal-temperature refrigerant which is sent by a normal-temperature tank; the low temperature refrigerant with temperature reduced enters a refrigerant storage tank for standby and is finally delivered to a cold energy user; the normal-temperature natural gas with temperature increased enters the pipeline. The method which utilizes natural gas pressure energy has convenient and practical whole process technique and high efficiency, spends little investment on the self-pressure energy in the pressure reduction process of the high pressure natural gas which is recovered by a pressure modulating station, converts the pressure energy into the cold energy with low operation cost, leads the cold energy to be used by cold quantity users of cold storages, cold water air conditioners, wasted rubber deep-cold crushing round the pressure modulating station by means of the refrigerant, etc., or to be made into ice blocks and dry ice products for abroad sale, etc., thus gaining huge economic benefits, improving the utilization ratio of the energy resource and eliminating the safe hidden trouble which is generated by sudden coolness of the equipment in the normal pressure modulating process.

Owner:GUANGZHOU GAS

Mobile phone identification code saw-tooth anti-counterfeiting method

ActiveCN104794629ANo additional printing costsEasy to identifyStampsCharacter and pattern recognitionDrug productComputer science

The invention provides an anti-counterfeiting method by utilizing an intelligent mobile phone to identify code saw-teeth. The method comprises the steps of amplifying and photographing saw-teeth of a product code and image-text margin; storing the photographed saw-tooth characteristic information into an anti-counterfeiting system database to be used as anti-counterfeiting characteristic filing information. The method is simple and easy to implement, and for the user product of the existing drug electronic supervision code, the amplified picture of the saw-teeth is stored when the product is under the automatic quality inspection and is used as the anti-counterfeiting characteristic filing information to be stored. By implementing the method, the equipment investment is not increased, the procedure is not increased, the cost is not increased, an effective anti-counterfeiting function of the product can be realized, and the bug of the digital anti-counterfeiting technology such as the telegram code anti-counterfeiting technology can be blocked up.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

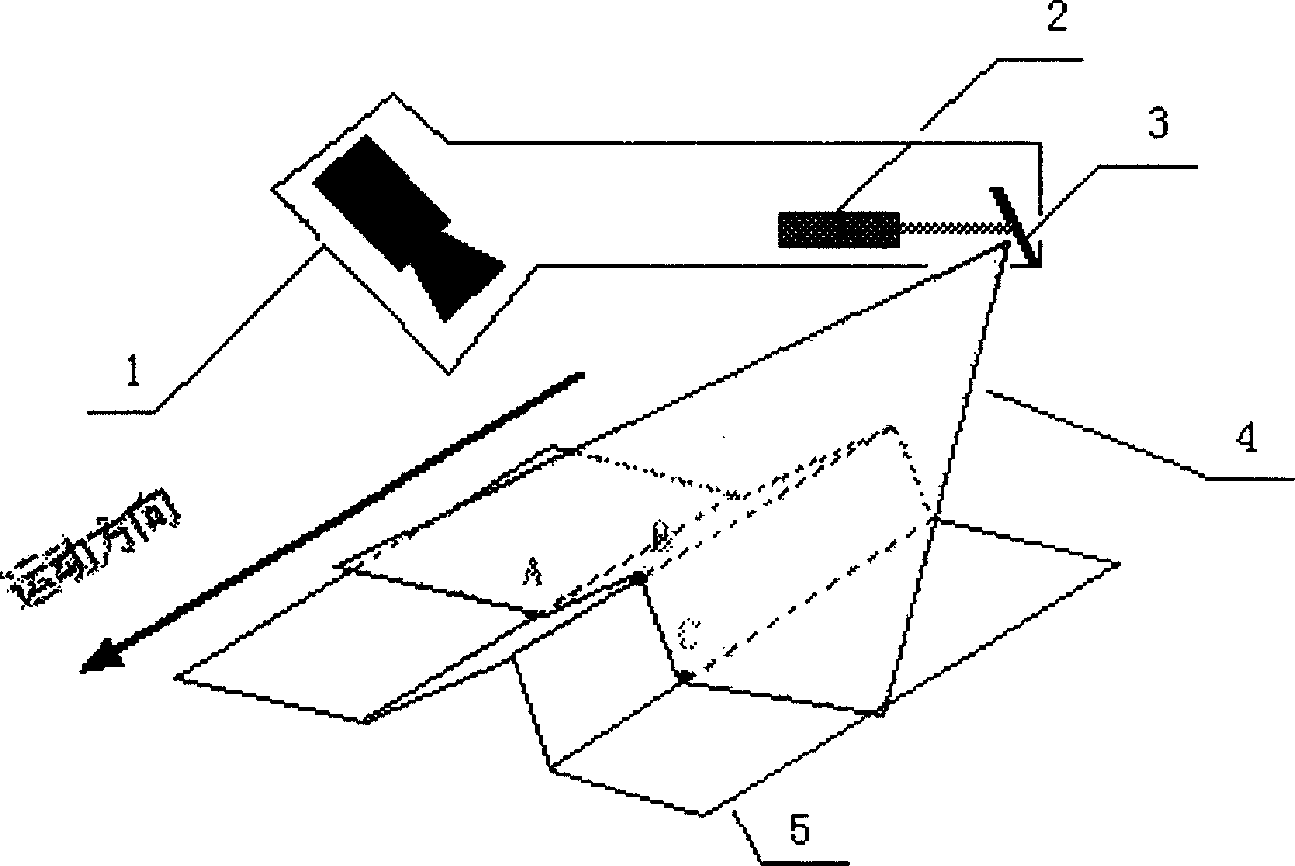

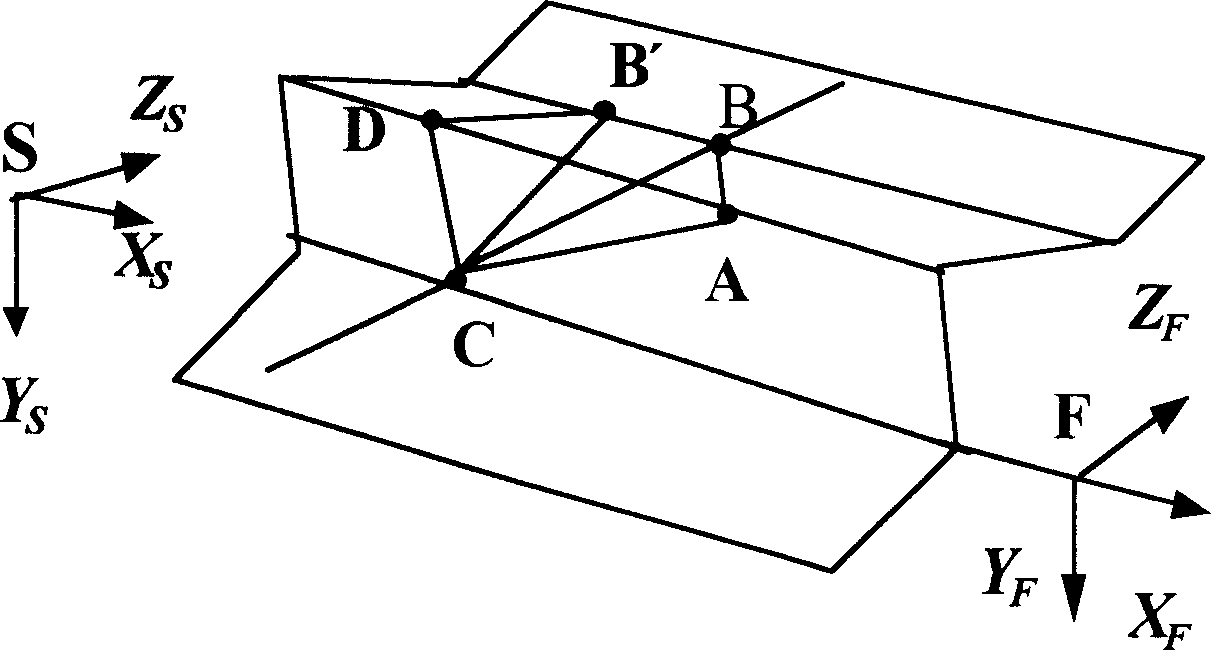

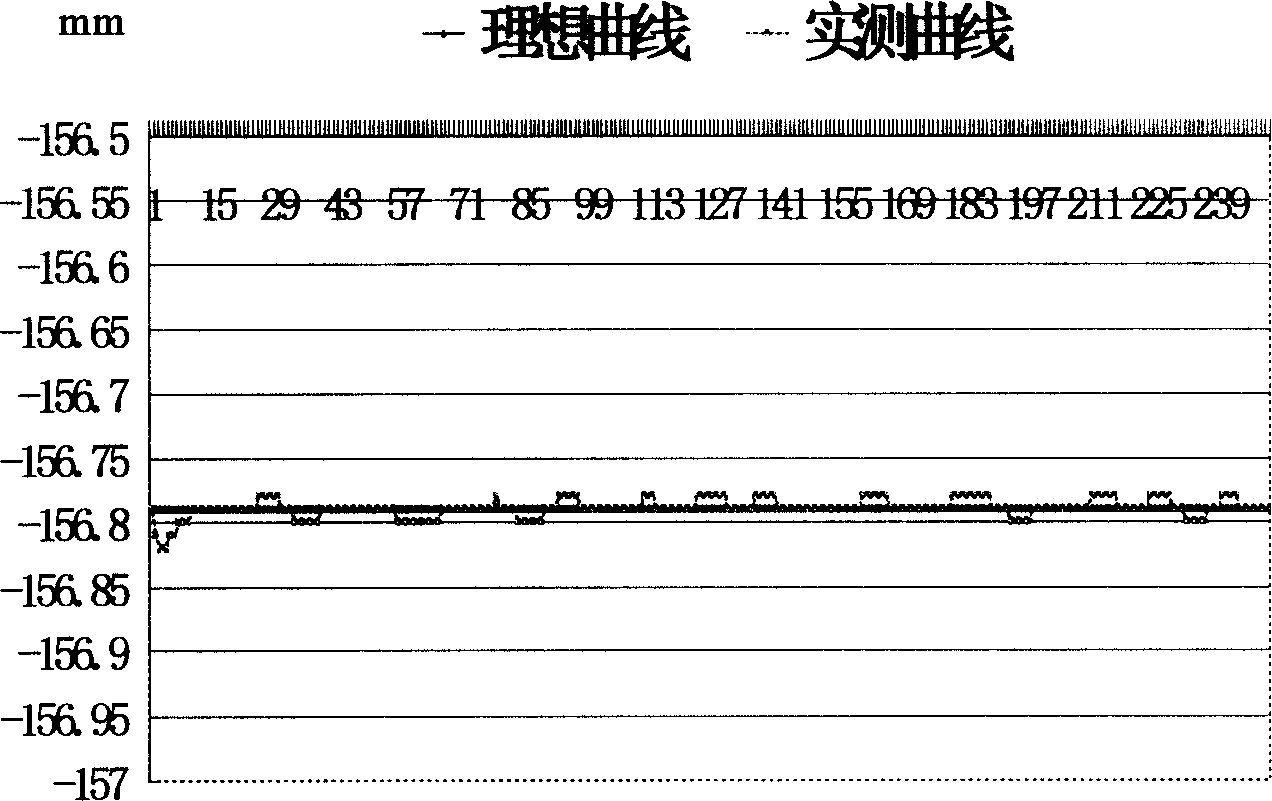

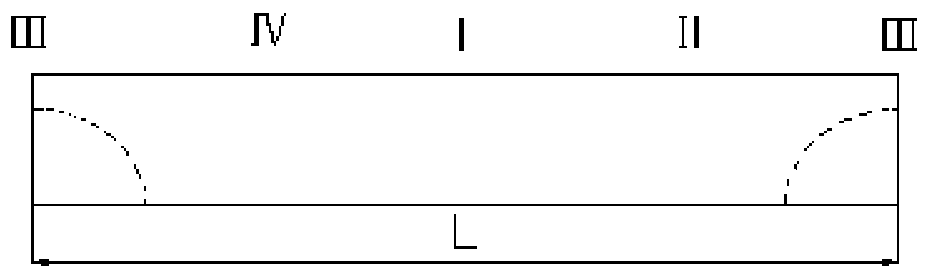

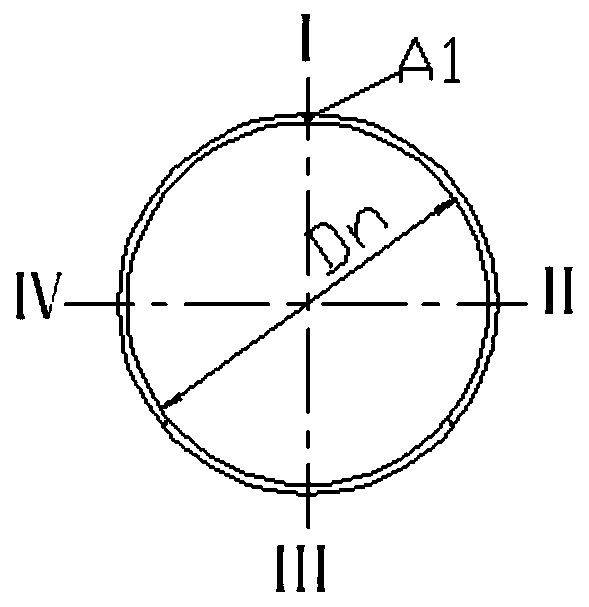

Robot straight line track characteristeric measuring method and measurer used thereof

InactiveCN1512135ALow costPractical costUsing optical meansManipulatorContinuous scanningMeasurement device

The present invention belongs to the technology of robotics and is especially robot straight line track characteristic measuring method and device. Based on structural light 3D visual measurement principle, linear structural light is made to combine with CCD camera to constitute sensor and form geometric model of structural light reflecting imaging. Sensor in motion is used to scan and image the reference object, and visual image processing technology is adopted to calculate the continuous position and gesture relationship between the sensor and the reference coordinate system, so as to realize the detection of robot linear track. The present invention has low cost, convenient use and high performance, is practical, and may be used in the non-contact measurement of robot linear track and repeatability.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Method for improving fruit tree planting survival rate

ActiveCN103238433AEfficient cultivationSimple and fast operationHorticultureFruit treeObserved Survival

The invention discloses a method for improving fruit free planting survival rate. The method includes the steps of firstly, digging a planting pit; secondly, mixing organic compost fertilizer; thirdly, selecting healthy and strong nursery stock; fourthly, watering; and fifthly covering white thin films. By the method, survival rate of nursery stock can be increased effectively, healthy growth of nursery stock can be guaranteed, production cost is lowered greatly, and significance for realizing expected targets is achieved.

Owner:SICHUAN AAS HORTICULTURE RES INST

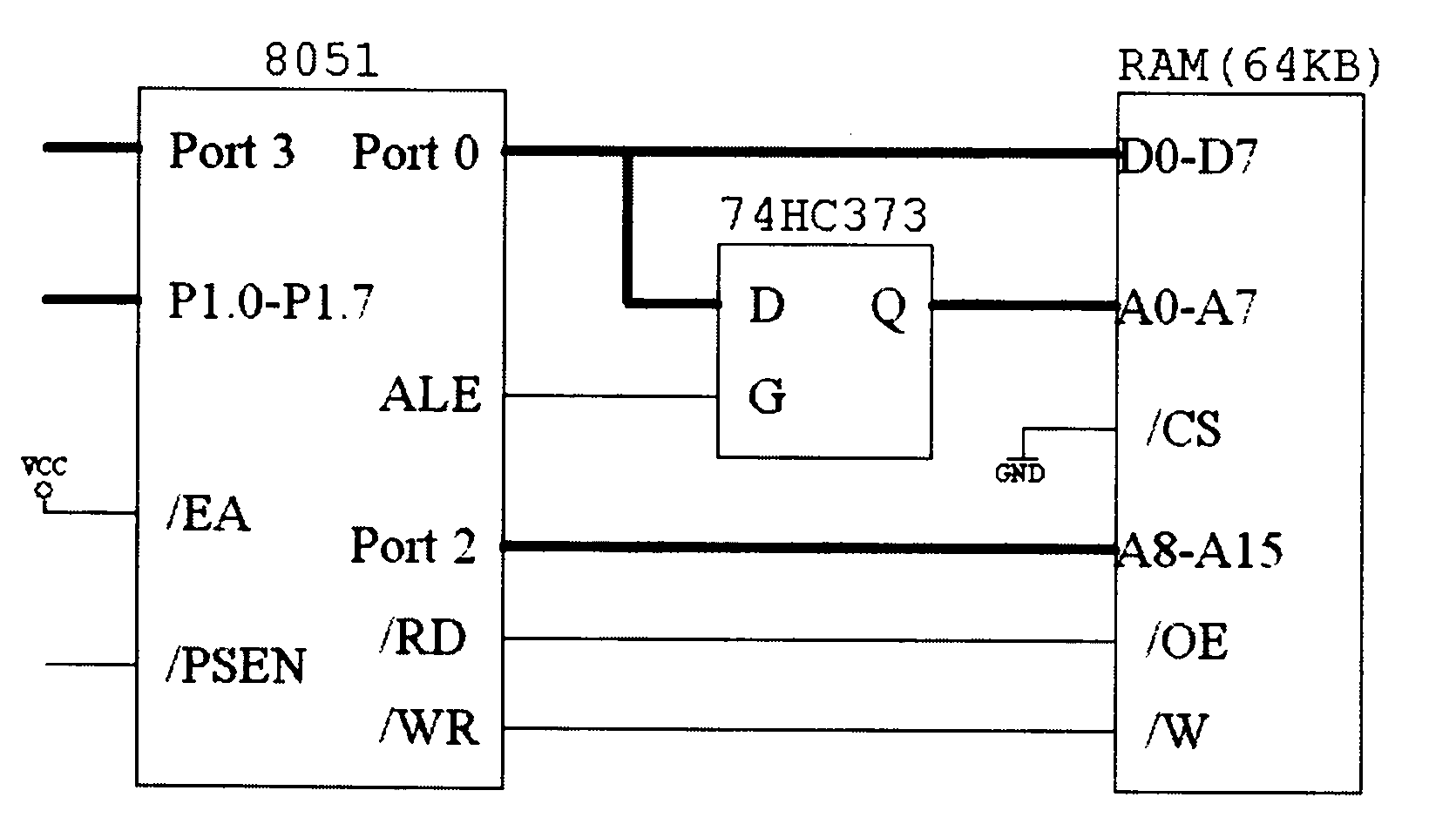

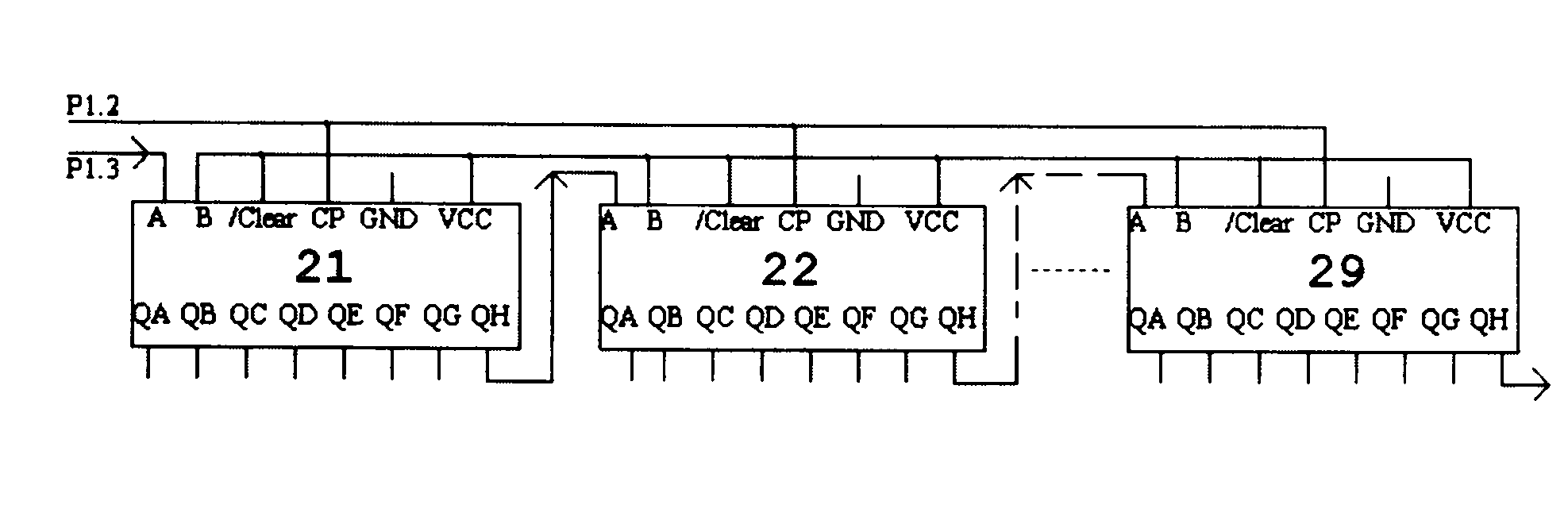

Pet trample-preventing alarming device and method for classifying foot shapes by measuring length of area

InactiveCN102339512ATechnical economyPractical technologyElectric/magnetic area measurementsBurglar alarm by pressureMicrocontrollerEngineering

The invention relates to a pet trample-preventing alarming device and a method for classifying foot shapes by measuring a length of an area, which comprises the pet trample-preventing alarming device part and the method part for classifying the foot shapes by measuring the length of the area. The method is reflected on a program for classifying the foot shapes by measuring the length of the area. The alarming device consists of a rectangular framework, a battery pack, a single chip system, a serial-in parallel-out circuit, a parallel-in serial-in circuit and a music circuit, wherein the upper part and the bottom part of the rectangular framework are respectively provided with rows of electrode groups, and conducting wires of the electrode groups are sequentially connected to each parallel input end of the parallel-in serial-in circuit and each parallel output end of the serial-in parallel-out circuit. The program establishes a two-dimensional coordinate system according to array of the conducting wires of the two electrode groups, an area which is pedaled is scanned and detected by a single chip, an outline of the area is traced, a distance between every two outline points is calculated, the maximal distance between two outline points is stored and is adopted as the length of the area, the foot shape is judged, and the alarm is judged whether to issue. The pet trample-preventing alarming device is suitable for the antitheft alarming work.

Owner:CHONGQING TECH & BUSINESS UNIV

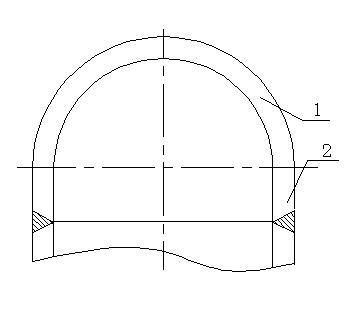

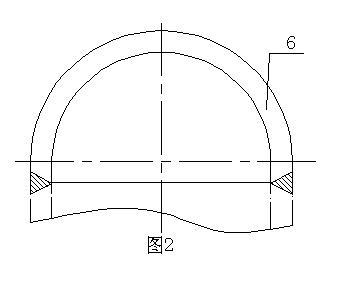

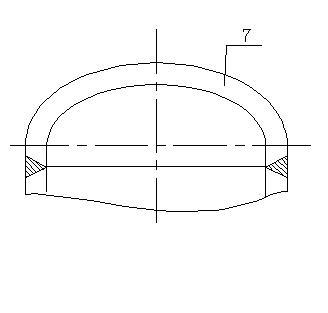

Reusable welded hydraulic cover of boiler and pressure vessel and manufacturing method of reusable welded hydraulic cover

ActiveCN102155538AIncrease material consumptionReduce utilizationPressure vesselsSingle useSteel plates

The invention discloses a reusable welded hydraulic cover of a boiler and a pressure vessel and a manufacturing method of the reusable welded hydraulic cover. In a hydraulic test in the conventional product factory for the boiler and the pressure vessel, the hydraulic cover which is formed by assembled welding of large-diameter welding pipes of a welding groove on a construction site serves as a welding temporary pressed element; the hydraulic cover is generally formed by oxygen-acetylene cutting of a steel plate; the stressed condition of a flat welding structure of the steel plate is poor; and the steel plate is thick and heavy and usually disposable so as to cause great waste. The welded hydraulic cover of the boiler and the pressure vessel comprises a cover (1), wherein hydraulic allowance (2) is formed at the lower end of the cover. The invention is applied to manufacturing of the boiler and the pressure vessel.

Owner:HARBIN BOILER

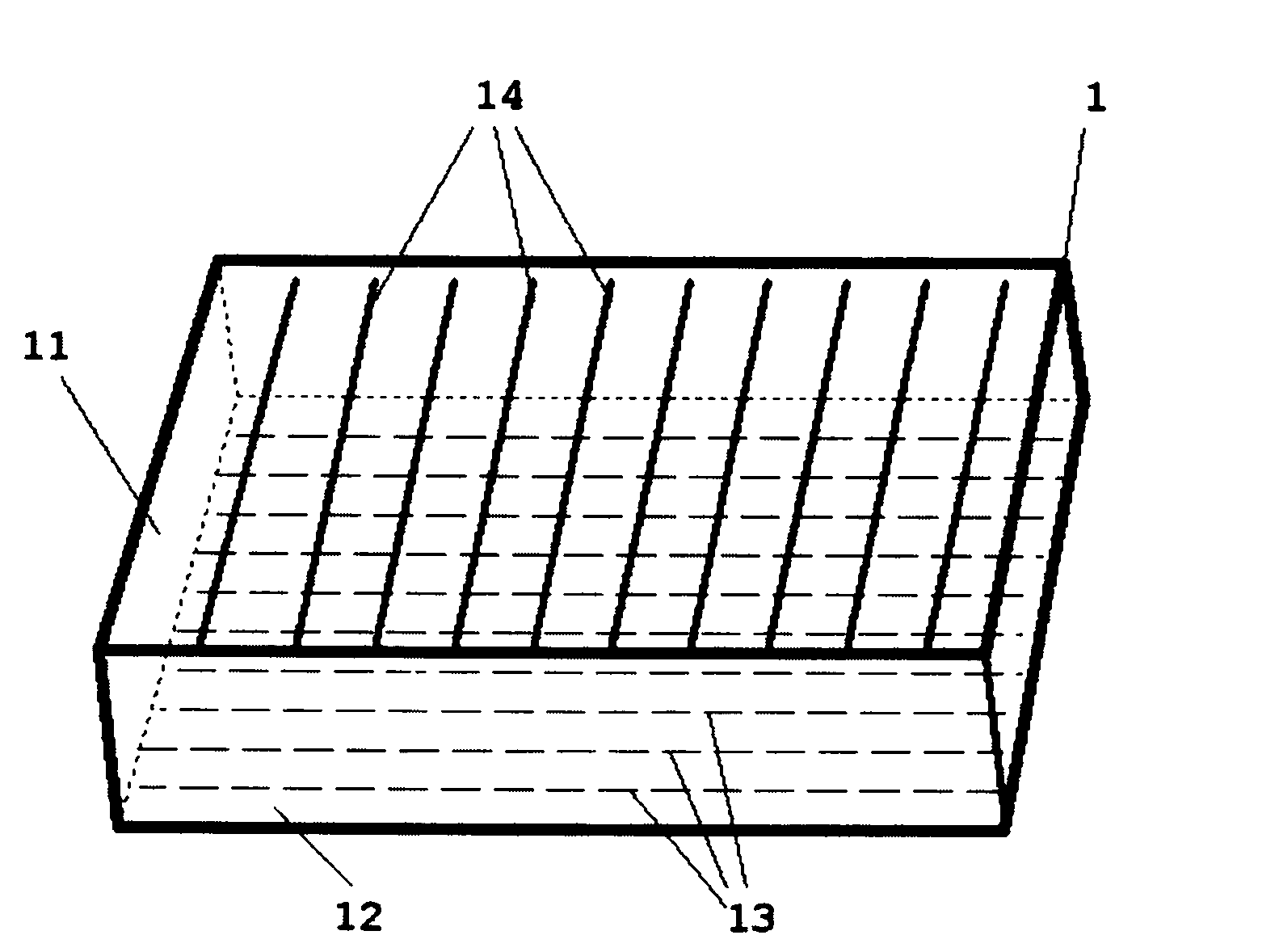

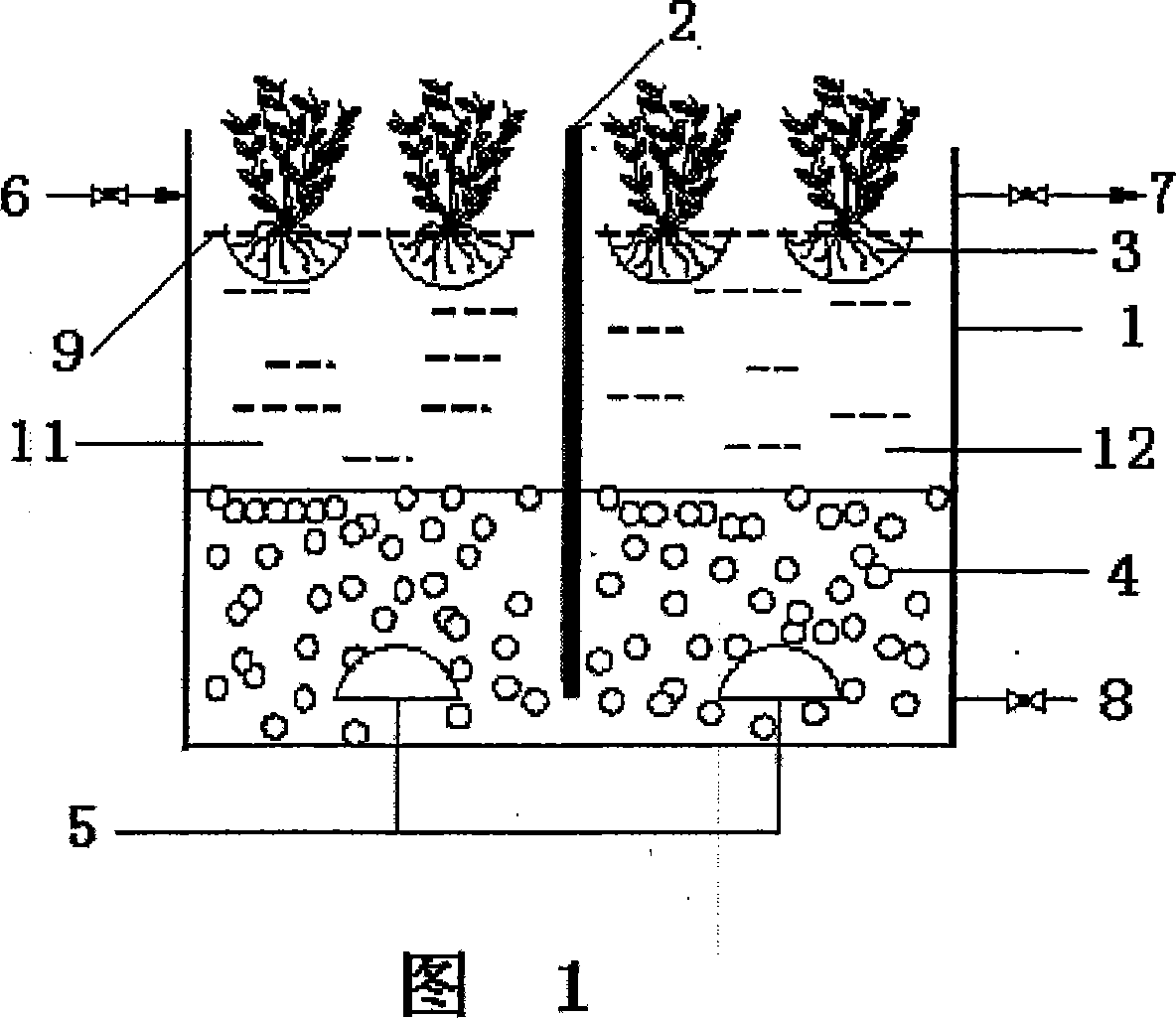

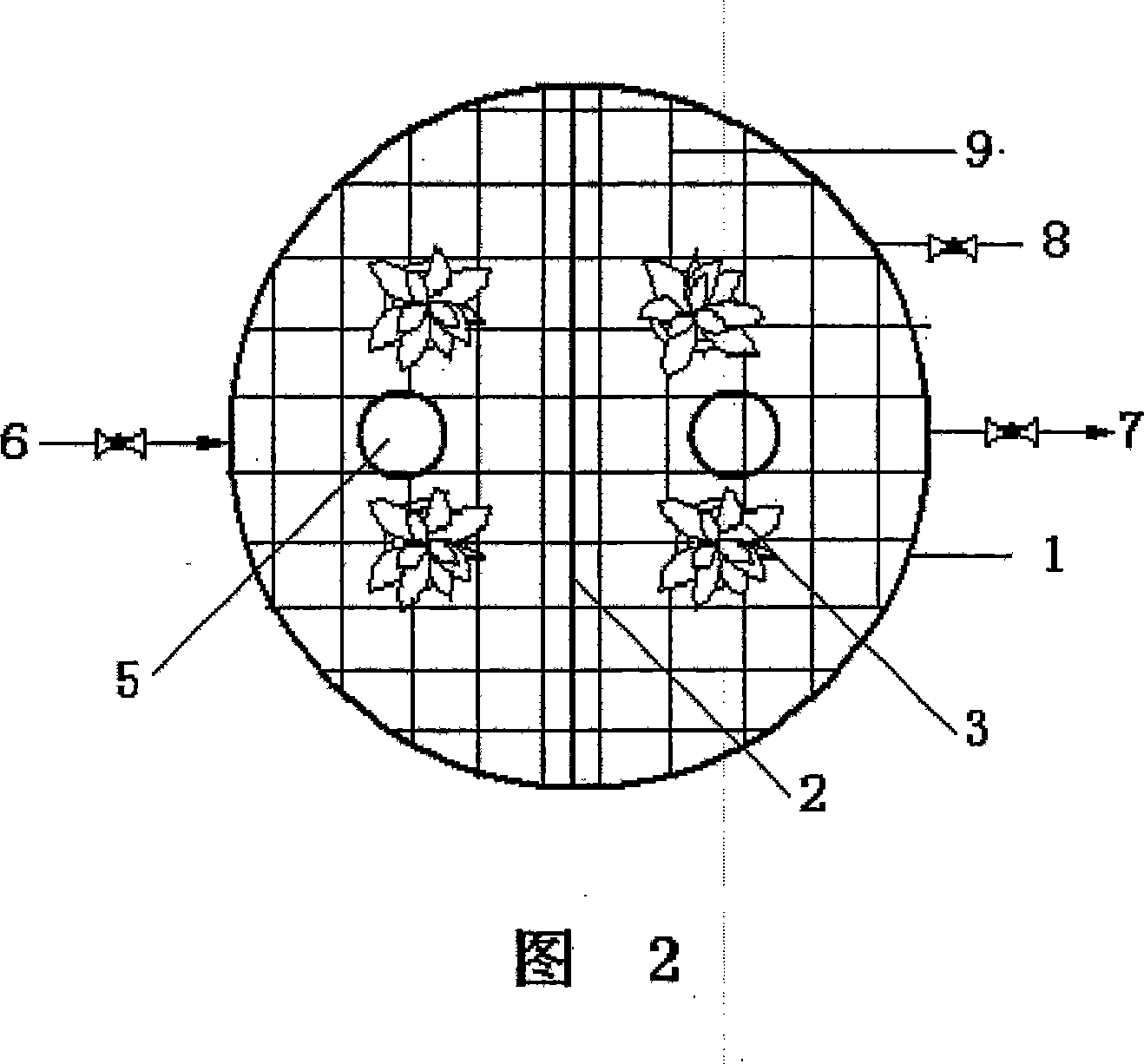

Zoology unit type sewage treatment facility in high performance

InactiveCN101050029ASimple structureSimple processSustainable biological treatmentBiological water/sewage treatmentPlant rootsWastewater

This invention discloses a high-efficiency wastewater treatment apparatus assembled from ecological units. Each ecological unit is composed of a main body, a central diaphragm, a plant layer, a filler layer, an aerator and pipelines. The central diaphragm, set vertically at the upper part of the main body, divides the main body into two through connected functional chambers. The upper parts of the two functional chambers have water inlet valves or water outlet valves. A waste discharge valve is set at the lower part of the main body. The aerator is set at the bottom of the main body. A plant root fixation net is set at the top of the functional chambers. The filler layer is set at the lower part of the functional chambers. The wastewater treatment apparatus has such advantages as simple structure, simple process, practicable technique, high working efficiency, and low energy consumption, and can be widely used in domestic wastewater treatment for communities, offices and institutes.

Owner:昆明麦能环境工程有限公司

Preservation method for fresh lycium barbarum

InactiveCN103416483AReduce processing costsSimple and fast operationFruits/vegetable preservation by freezing/coolingPreservativePreservation methods

The invention relates to a preservation method for fresh lycium barbarum. The preservation method for the fresh lycium barbarum includes the following steps of (1) taking the fresh lycium barbarum, washing the fresh lycium barbarum, removing impurities on the surface of the fresh lycium barbarum, soaking the fresh lycium barbarum in ozone solution with concentration of 0.5-1.0 mg / L for 30-40s, draining the fresh lycium barbarum, washing the fresh lycium barbarum with purified water, draining the fresh lycium barbarum, blow-drying the surface of the fresh lycium barbarum, putting the fresh lycium barbarum in a preservation plate for later use, (2) putting every 5-8kg of the fresh lycium barbarum processed through the step (1) into a freshness protecting package, putting the packaged fresh lycium barbarum with the opening of the package opened into a refrigeration house, precooling the fresh lycium barbarum, putting a pack of first preservatives and a pack of second preservatives into the freshness protecting package after the temperature of the core of the fresh lycium barbarum reaches 0-1 DEG C, tightening the opening of the package, putting the packaged fresh lycium barbarum into the refrigeration house with the temperature ranged from minus 2 DEG C to minus 1 DEG C, and refrigerating fresh lycium barbarum. The preservation method for the fresh lycium barbarum is low in process cost, simple and convenient to operate and practical in technology, and prolongs the preservation period of the fresh lycium barbarum.

Owner:宁夏林业研究院股份有限公司

Method for controlling natural fruit setting of Kyoho grapes

ActiveCN105993823AReduce the incidence of vineyard diseasesEnsure normal fruit settingFertilising methodsCultivating equipmentsControl functionMagnesium

The invention provides a method for controlling natural fruit setting of Kyoho grapes. The method comprises the steps of perfecting rain shelter infrastructure construction, managing a fertilizer and water, enhancing nutrition supply of tree bodies, reapplying an organic fertilizer, strictly controlling a nitrogenous fertilizer, applying a phosphate fertilizer and a potash fertilizer, supplementing calcium, magnesium and boron micro-element fertilizers and strengthening prevention and control of diseases and insect pests, ensuring normal fruit setting, controlling the treetops and hastening blossom before flowering, improving the nutrition absorption capacity of fruit clusters and conducting effective fruit cluster management in the flowering and fruit setting periods. According to the method for controlling natural fruit setting of the Kyoho grapes, by means of artificial measures, the nutrient-flow dynamic balance regulation and control function of the Kyoho grape tree bodies is stimulated, the fruit dropping speed is accurately controlled, the optimal time point of fruit setting is mastered in time, uniform fruit dropping is guaranteed, and fructification is controlled accurately; the fruit product quality is vigorously improved on the basis of ensuring the normal yield, and the labor cost for fruit thinning can be greatly reduced.

Owner:邓万良

Fresh-keeping method for fresh eating medlar

InactiveCN102422871AFor long-term storageEmerald green fruit stalkFruits/vegetable preservation by freezing/coolingAdditive ingredientPre cooling

Owner:QINGHAI TSINGHUA BIOTRY BIO TECH +1

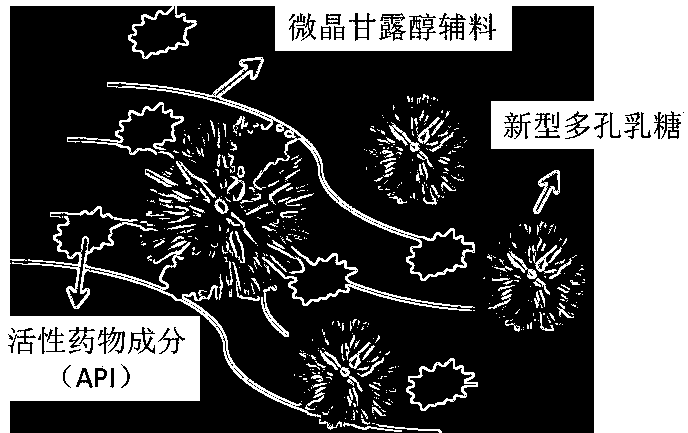

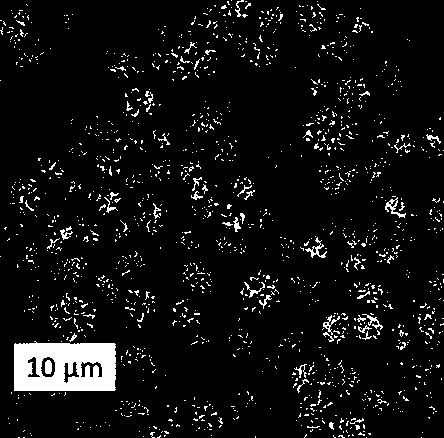

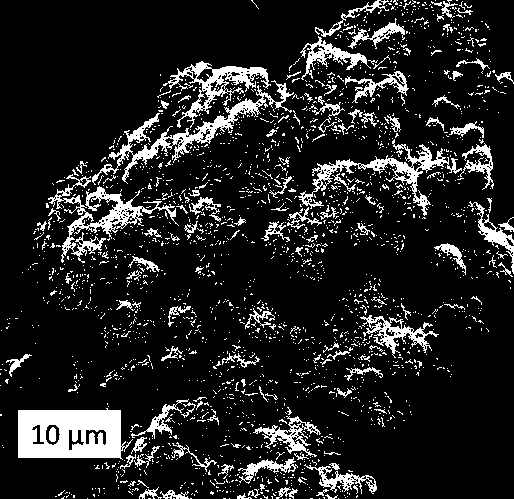

Quick-acting orally disintegrating tablet and powder based on novel porous lactose and microcrystalline mannitol auxiliary materials

The invention provides a quick-acting orally disintegrating tablet and powder based on novel porous lactose and microcrystalline mannitol auxiliary materials, which is prepared from the following components in parts by mass: 0.5-60% of active pharmaceutical ingredient, 0-99.5% of the novel porous lactose (anhydrous alpha / beta mixed crystal lactose), 0-99.5% by mass of the microcrystalline mannitol(alpha / delta-mannitol mixed crystals) ; the quick-acting orally disintegrating tablet and powder based on the novel porous lactose and the microcrystalline mannitol auxiliary materials can be completely dissolved in the mouth within 2 seconds to 5 minutes, and effectively release active medicinal ingredients. The quick-acting orally disintegrating tablet and powder aims at the physical changes ofthe lactose and mannitol, so that the effect of uniformly and quickly releasing the orally disintegrating tablets is achieved; the method is practical in technology and can be industrialized easily.The quick-acting orally disintegrating tablet and powder directly or indirectly upgrades all existing orally disintegrating tablets and powders using the lactose and / or mannitol by upgrading auxiliarymaterials of the orally disintegrating tablets and powders.

Owner:谭淞文

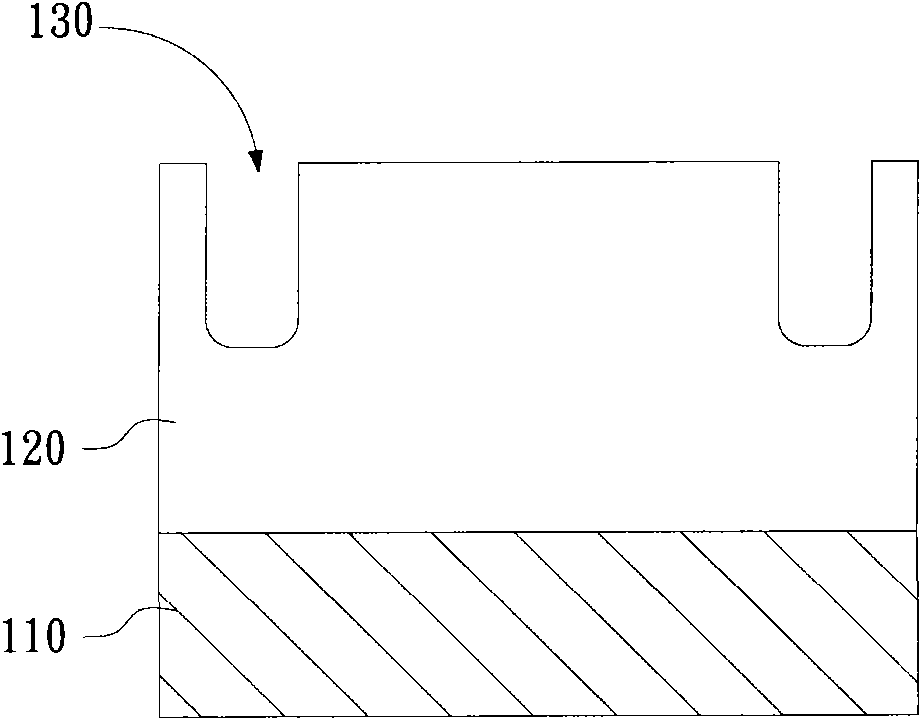

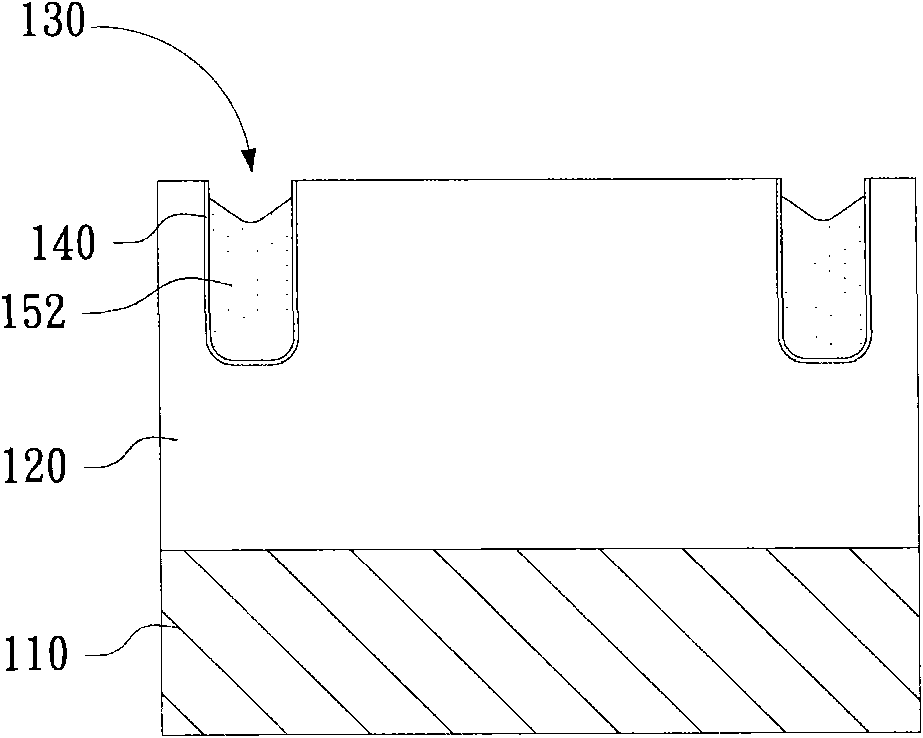

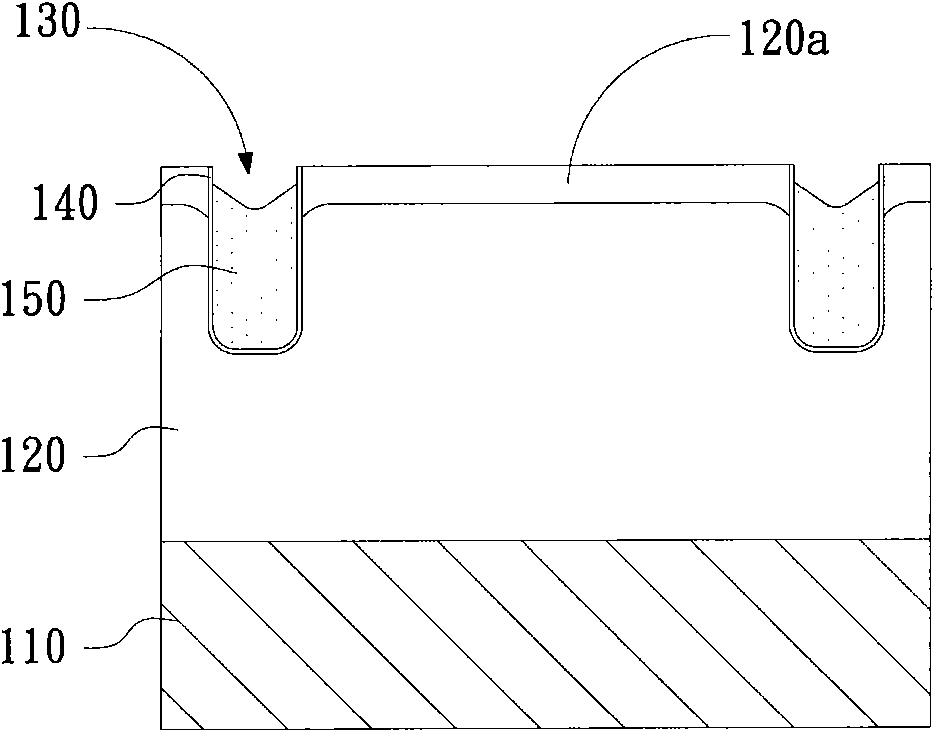

Trench gate metal oxide semiconductor field effect transistor and manufacturing method thereof

InactiveCN101656213ASimple structureEnhance the outstanding effectSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorPolysilicon gate

The invention relates to a trench gate metal oxide semiconductor field effect transistor and a manufacturing method thereof. The method comprises the following steps: manufacturing a first conductiveepitaxial layer on a silicon substrate; manufacturing a plurality of trenches on the epitaxial layer; performing overall ion implantation of a first conductive doping material on the epitaxial layer;manufacturing a polysilicon pattern layer covering the trenches and the epitaxial layer in a preset range around the trenches; implanting a second conductive doping material on the epitaxial layer through the polysilicon pattern layer; importing a doping material to form a well area having the second conductive doping material; implanting the first conductive doping material in the well area through the polysilicon pattern layer to form a plurality of first doped areas; implanting the doping material of the first doped areas to form source electrode doped areas close to the trenches; and removing the polysilicon pattern layer above the epitaxial layer to form a polysilicon gate. The method can improve the depth distribution of the sell area of the trench gate metal oxide semiconductor field effect transistor and avoiding the effectiveness loss caused by the coverage of the gate trenches by the well area.

Owner:NIKO SEMICON

Natural wood fiber carrier for microbial immobilization and preparing method of natural wood fiber carrier

InactiveCN106926334AAdjust and optimize porosityImprove bindingWood treatment detailsMicroorganism based processesFiberHigh pressure

The invention relates to the field of microbial fermentation, in particular to a natural wood fiber carrier for microbial immobilization and a preparing method of the natural wood fiber carrier. The method includes the following steps that (1) natural wood fiber materials relatively even in texture are selected, and mechanical pretreatment is carried out on the natural wood fiber materials; (2) water is added into a high temperature and high pressure reaction still, and then the natural wood fiber materials treated in the step (1) are added; (3) the natural wood fiber materials obtained in the step (2) and water are jointly heated and pressurized to the appointed temperature and appointed pressure so as to make a hydrothermal reaction, and the hydrothermal reaction is continuously made for appointed time; (4) after the hydrothermal reaction in the step (3) is finished, the temperature and pressure in the high temperature and high pressure reaction still are decreased, and the natural wood fiber materials obtained after hydrothermal treatment are taken out; and (5) the natural wood fiber materials obtained in the step (4) are washed and dried to obtain the natural wood fiber carrier. By means of the natural wood fiber carrier and the preparing method, the microorganism fixing effect is improved, significance in microbial immobilization is achieved, and the application prospect is wide.

Owner:BEIJING NORMAL UNIVERSITY

Preparation method of roxburgh rose compound beverage

InactiveCN110122717AReduce heavy bitter tasteUnique action to reduce heavy bitter tasteFood ingredientsFruit juiceFood flavor

The invention discloses a preparation method of a roxburgh rose compound beverage. Local-feature roxburgh rose and tea leaf are scientifically matched, unique effect of strong bitterness that roxburghrose juice has originally can be relieved through effect of tea juice flavoring substance in optimizing and improving roxburgh rose taste and proper matching of the tea juice and roxburgh rose flavor, and the common problem that conventional roxburgh rose juice is improper in taste is solved; processing stability is improved by utilizing coordinated protection of rich flavone polyphenol that theroxburgh rose and the tea leaf contain, selected specified lactic acid strain fermentation effectively releases nutritional and functional active substances of the roxburgh rose and the tea leaf, anda novel compound special nutritional fermented product is obtained, so that efficient utilization paths of raw material resources are expanded. The preparation method is practical, simple and feasible, and the compound beverage is outstanding in quality comparison advantage.

Owner:GUIZHOU UNIV

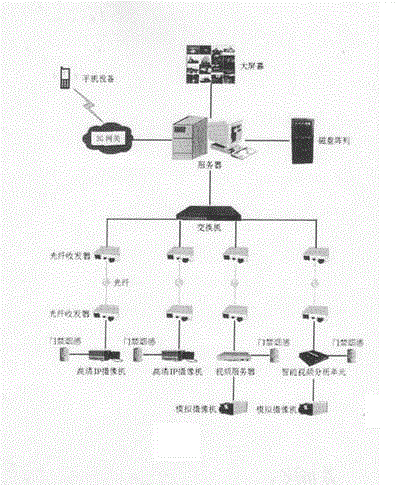

Unattended transformer substation integrated monitoring system

InactiveCN103607575AReal-time understandingReal-time graspClosed circuit television systemsTransceiverTransformer

The invention provides an unattended transformer substation integrated monitoring system, and belongs to the field of electric technologies and equipment. According to the technical scheme, the system is composed of a center management server, a disk array, a large screen, network transmission equipment and 3G gateway equipment. Videos and monitoring data of transformer substations are collected and encoded through equipment at the front ends of the transformer substations, and the encoded data are transmitted to the center management server through a fiber optical transceiver and a network switch of the network transmission equipment for monitoring, storage, forwarding control and management. The large screen is used for displaying high-definition monitoring images. The disk array is mainly used for storing video stream data. The 3G gateway equipment is used for transmitting warning signals to a designated mobile phone terminal through a 3G network. The unattended transformer substation integrated monitoring system has the advantages that the transformer substations can be monitored and supervised, situations can be conveniently and directly grasped in real time, response can be made in time, and the system is advanced in design, practical in technology, efficient in operation, easy and convenient to maintain, and safe and reliable.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ANYANG POWER SUPPLY

Hydraulic motor fault detection method, device and system and excavator

PendingCN113503289ANarrow down the scope of troubleshootingImprove accuracyFluid-pressure actuator testingServometer circuitsHydraulic motorControl engineering

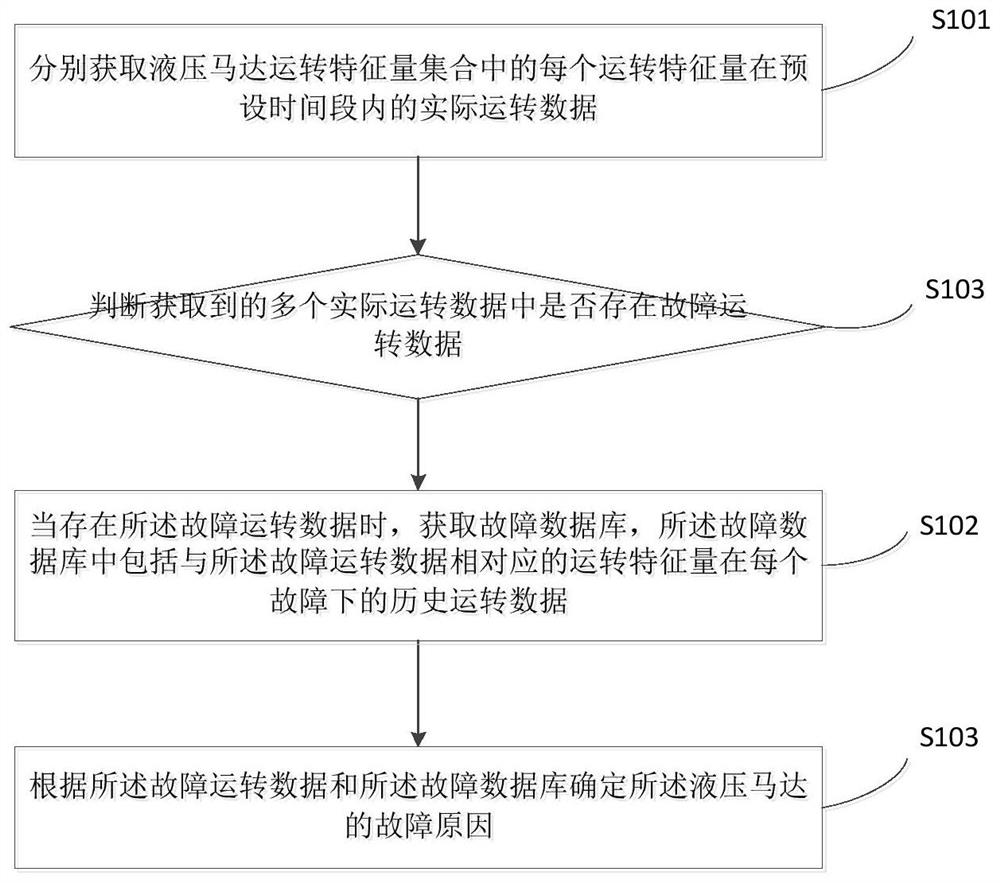

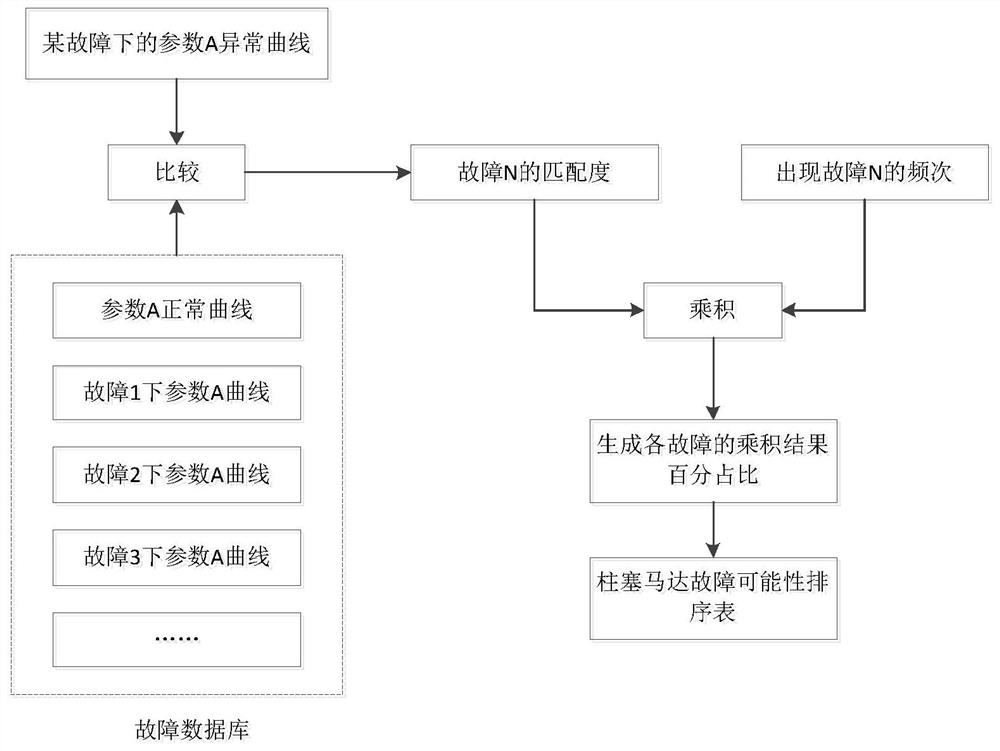

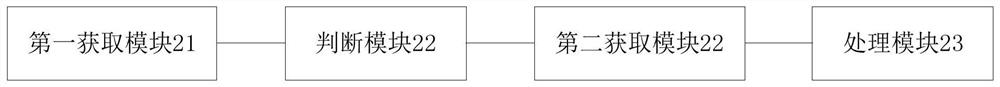

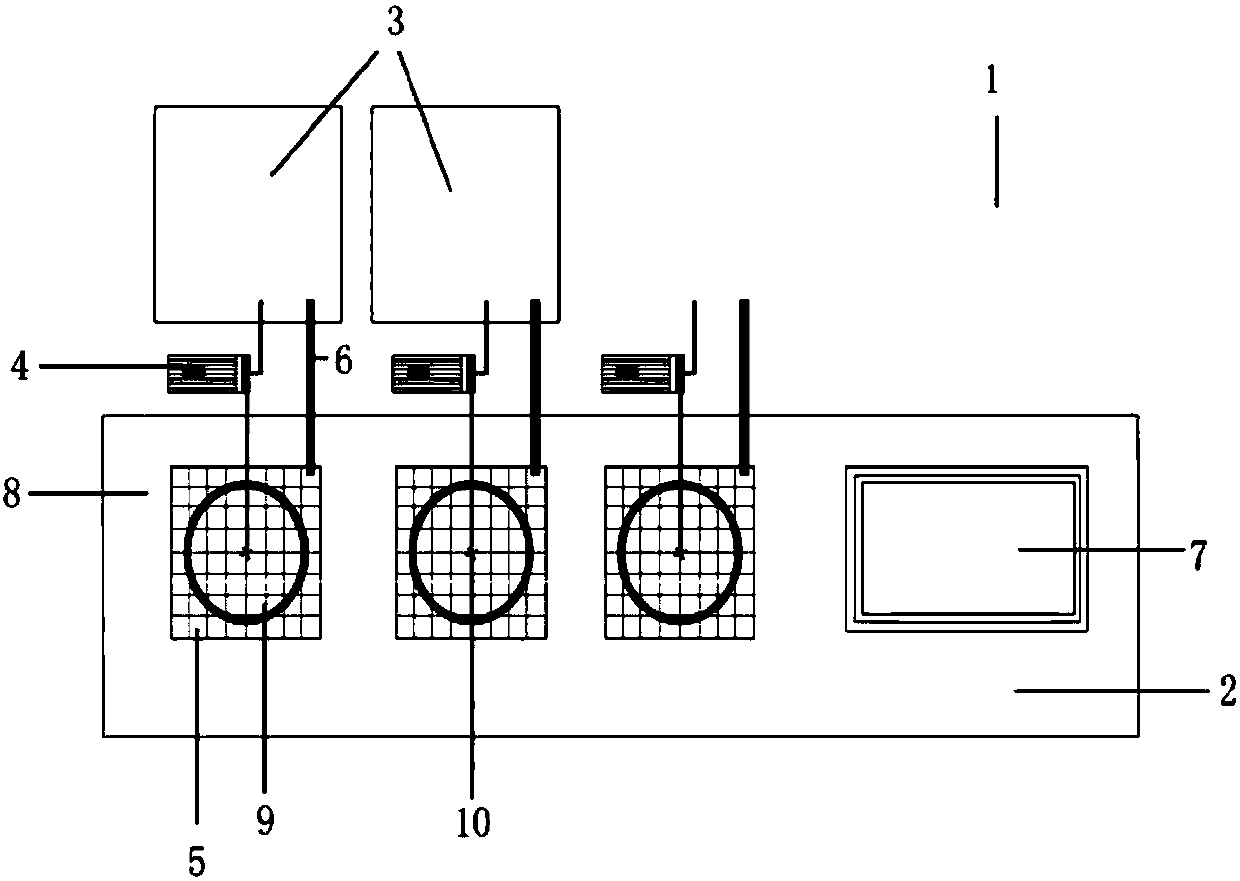

The invention discloses a hydraulic motor fault detection method, device and system and an excavator. The hydraulic motor fault detection method comprises the following steps: respectively obtaining actual operation data of each operation characteristic quantity in a hydraulic motor operation characteristic quantity set in a preset time period; judging whether fault operation data exists in the multiple obtained actual operation data or not; when the fault operation data exists, obtaining a fault database, wherein the fault database comprises historical operation data of the operation characteristic quantity corresponding to the fault operation data under each fault; and determining the fault reason of the hydraulic motor according to the fault operation data and the fault database. Therefore, automation of data analysis during fault detection of the hydraulic motor can be realized, so that the efficiency and precision of fault detection are improved, and the labor cost is reduced.

Owner:杭州力龙液压有限公司

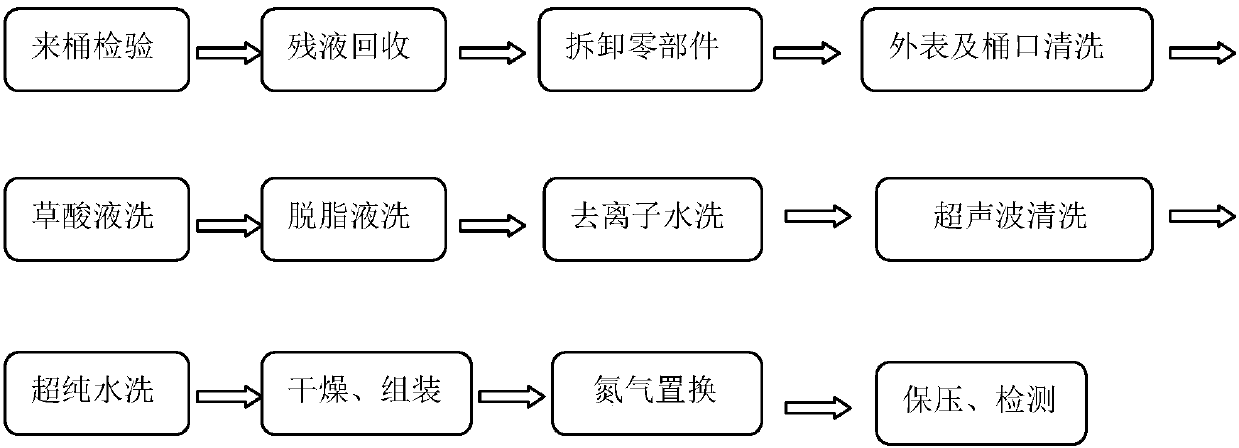

Electrolyte barrel cleaning method

InactiveCN109834097AReasonable layoutGuaranteed stable workHollow article cleaningDrying gas arrangementsAutomatic controlMegasonic cleaning

The invention discloses an electrolyte barrel cleaning method. The electrolyte barrel cleaning method is a process flow for cleaning an electrolyte barrel which has been used and meets secondary utilization, and the cleaning process flow comprises a cleaning process in the electrolyte barrel, wherein the cleaning process in the electrolyte barrel comprises an oxalic acid liquid washing procedure,a degreasing liquid washing procedure, a deionization water washing procedure, an ultrasonic cleaning procedure and a high-purity water washing procedure. According to the method, multiple proceduresare adopted, the cleaning is automatically controlled, the operation is safe, the cleaning effect is good, the production efficiency is improved, and the deep hole, the thin seam and the workpiece nook can also be cleaned up; no damage is caused to the surface of the workpiece, and the solvent, the heat energy, the working site and the labor are saved. Compared with an existing cleaning method, the whole process of the method is reasonable in layout, smooth in work and high in manual labor intensity reduction degree, high in working efficiency, safe and protected in place, low in equipment cost and capable of solving the problem of difficulty in maintenance.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Method for increasing fruit set percentage of fruit tree

InactiveCN107197700AReduce manufacturing costImprove fruit setting rateHorticulture methodsFruit treeFruit set

The invention discloses a method for increasing the fruit set percentage of a fruit tree. The method comprises the following steps: step one, preparation before implementation; step two, preparation of a solution; and step three, field spraying. According to the technical scheme, food of pollinating insects can be increased effective, so that the number of the pollinating insects is increased; and moreover, the humidity and the sugar content of flower stigmas can be increased, the moisturizing time of the flower stigmas is prolonged, the pollinating insects and attracted and used for pollinating for fruits and vegetables, the pollinating probability is increased, the fruit set percentage is increased, and the production cost is reduced. The method has important meaning on high quality and high yield of the fruit tree.

Owner:SICHUAN AAS HORTICULTURE RES INST

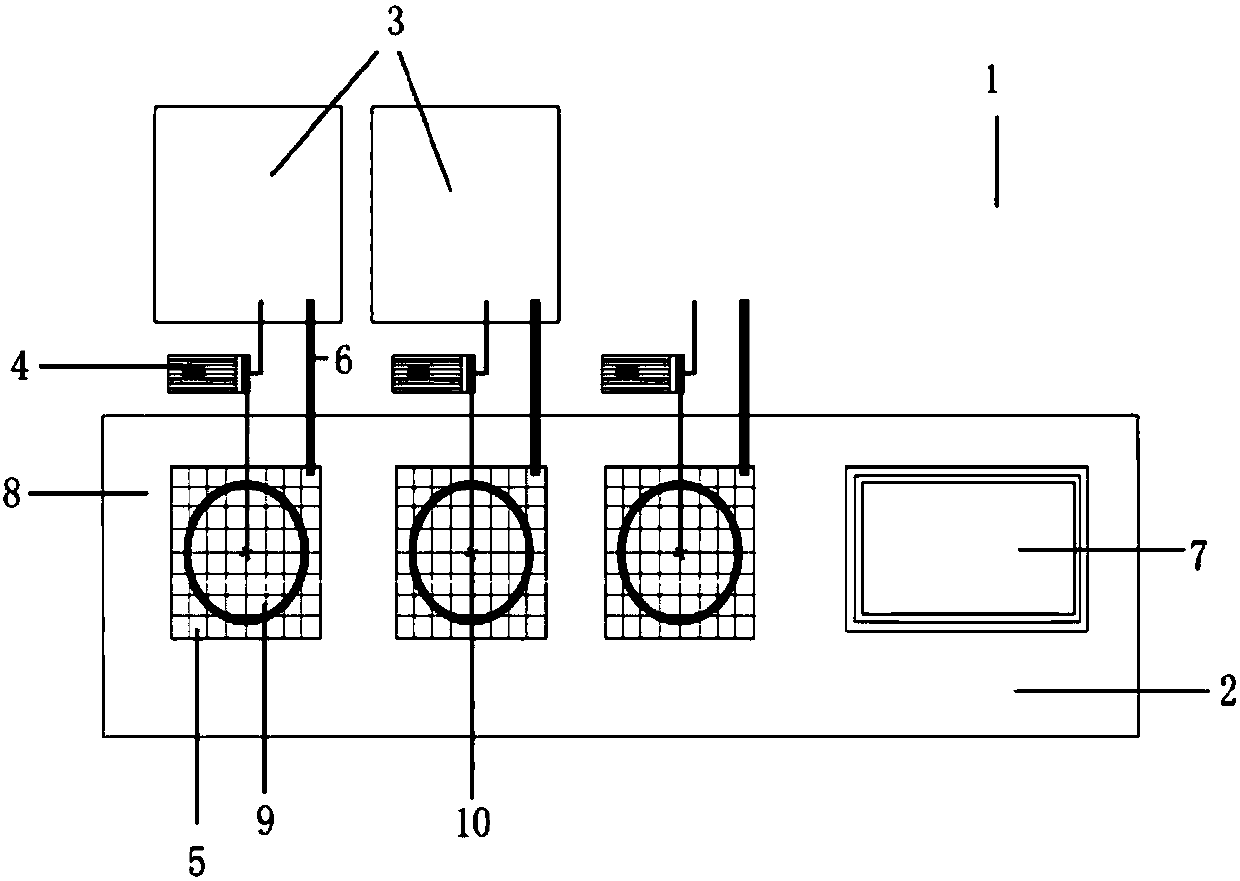

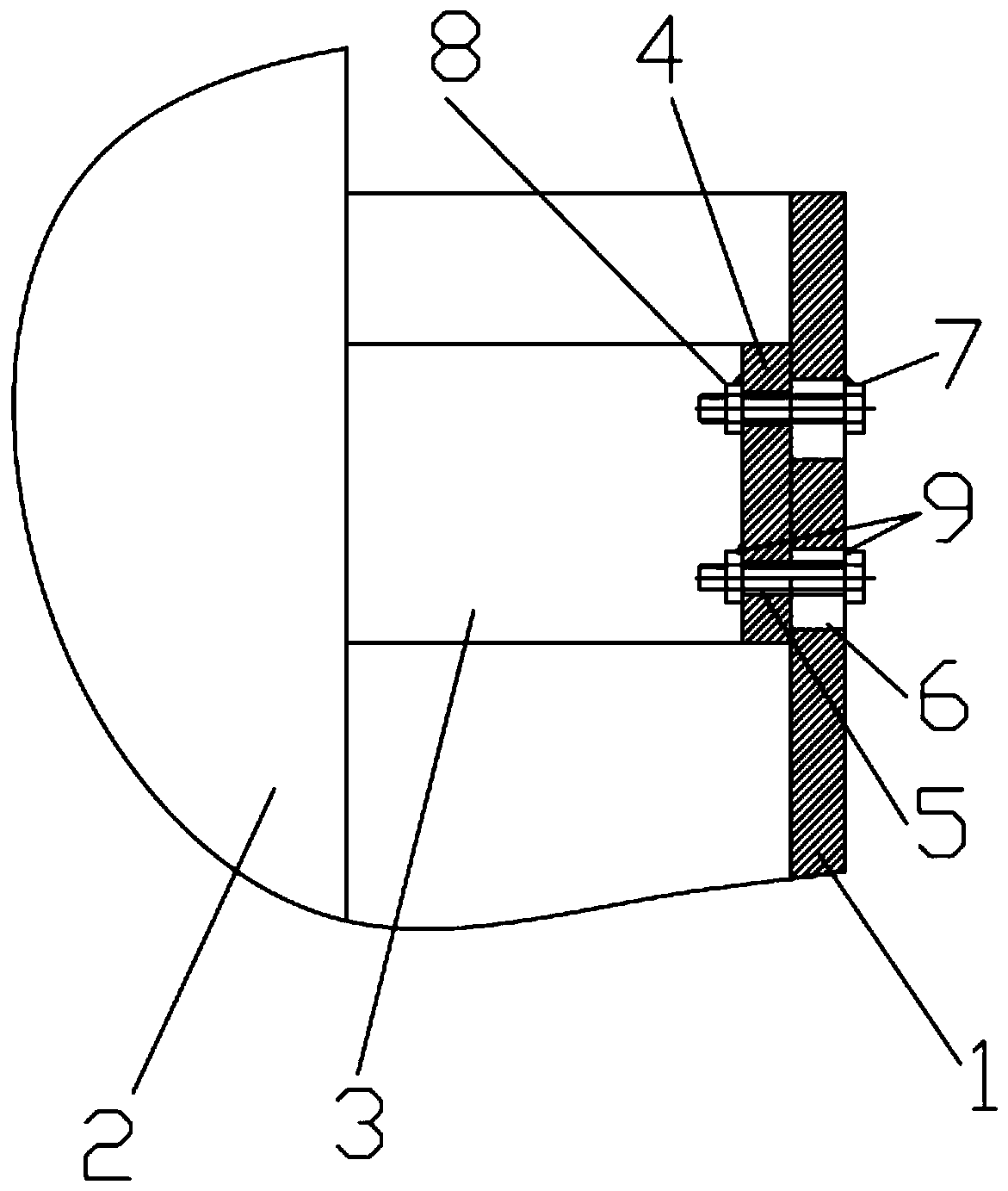

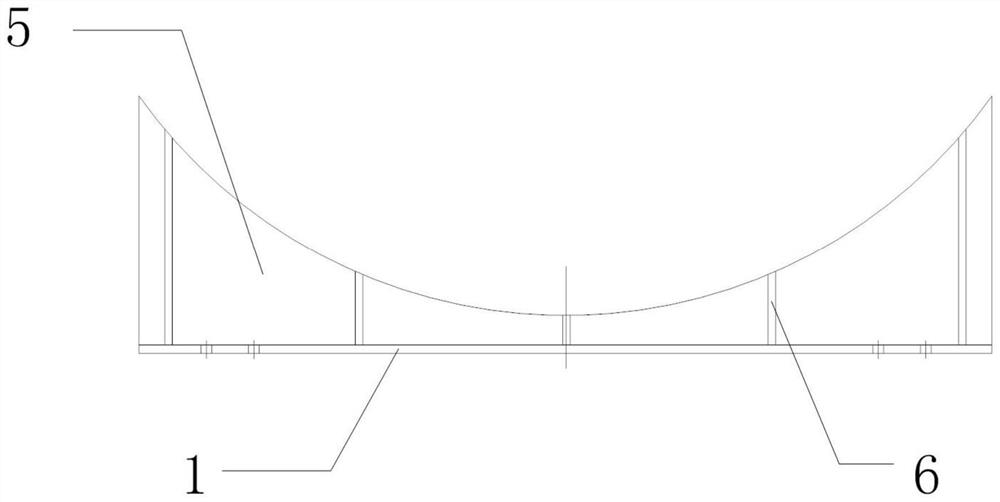

Connecting structure for rising cylinder and descending cylinder of gasification furnace and manufacturing method

ActiveCN110172364AOptimal Design StructureSimple preparation techniqueGranular/pulverulent flues gasificationManufacturing technologyEngineering

The invention provides a connecting structure for a rising cylinder and a descending cylinder of a gasification furnace and a manufacturing method and relates to the technical field of designing and manufacturing of the rising cylinder and the descending cylinder of the gasification furnace. The connecting structure for the rising cylinder and the descending cylinder of the gasification furnace aims at solving the problems of unreasonable hole structure, high manufacturing difficulty, poor machining and manufacturing quality and low production efficiency of the rising cylinder and the descending cylinder of the gasification furnace. The gasification furnace comprises the rising cylinder, the descending cylinder and 6-12 T-shaped supporting components which are arranged at the upper and lower ends of the rising cylinder; the T-shaped supporting components consist of distance plates and connecting plates; multiple circular holes are formed in the rising cylinder; multiple waist-shaped holes are formed in the connecting plates; the number of the circular holes is the same as that of the waist-shaped holes; the axes of the corresponding circular holes coincide with the corresponding waist-shaped holes; and through hexagon bolts and hexagon nuts, the rising cylinder is connected with the connecting plates through bolts. The invention provides the connecting structure for the risingcylinder and the descending cylinder of the gasification furnace and the manufacturing method.

Owner:HARBIN BOILER

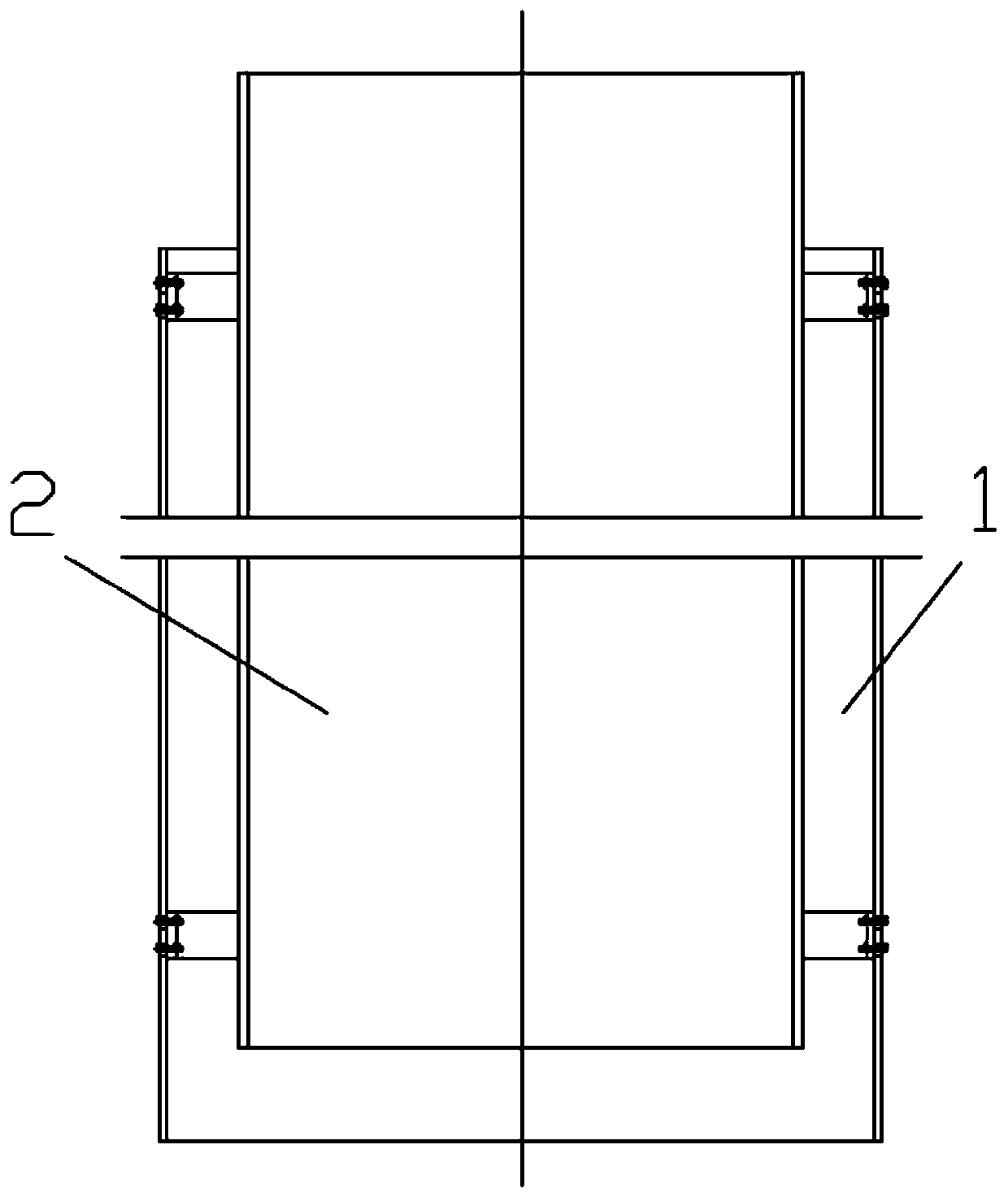

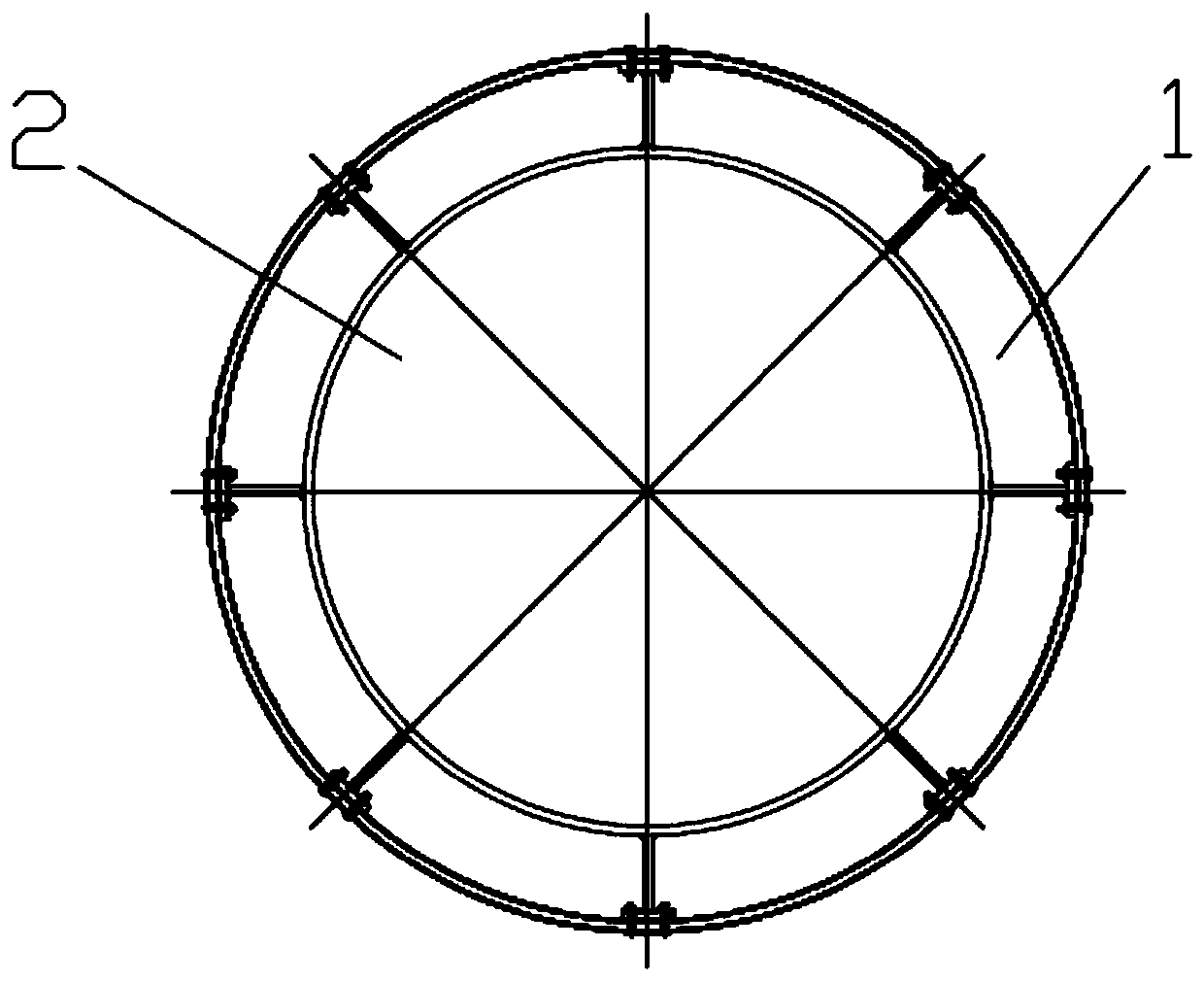

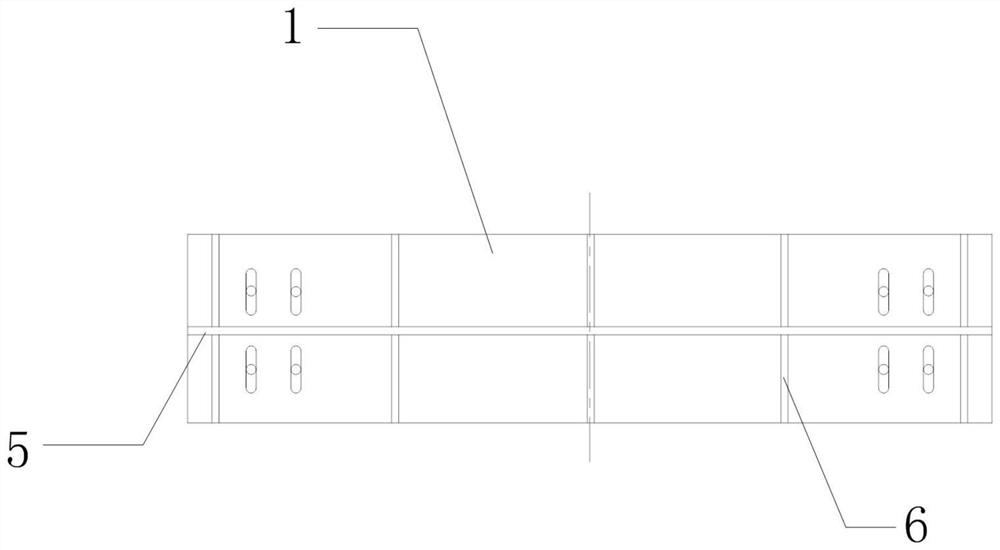

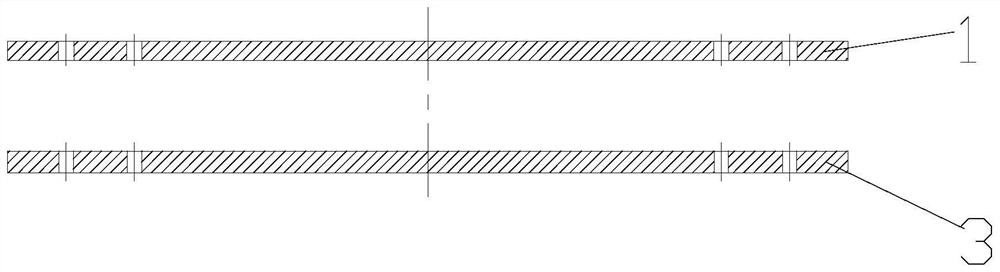

Manufacturing method of kidney-shaped holes in sliding support bottom plate of power station deaerator

ActiveCN111889981AImprove assembly qualityIncrease productivityPositioning apparatusMetal-working holdersNumerical controlPower station

The invention provides a manufacturing method of kidney-shaped holes in a sliding support bottom plate of a power station deaerator, and belongs to the technical field of design and manufacturing of sliding supports of large horizontal pressure bearing equipment. According to the manufacturing method, the bottom plate and a foundation plate are subjected to numerical control gas cutting blanking correspondingly, specifically, the kidney-shaped holes in the bottom plate are formed through numerical control gas cutting; the bottom plate and the foundation plate are corrected to be flat; the bottom plate, a vertical plate and rib plates are assembled and welded to form a support assembly; the bottom plate is corrected to be flat; the support assembly is put down to a flat face of the bottom plate to be fixed at the vertical position; a machined face of the bottom plate is machined, specifically, the flat faces of the opposite sides of the foundation plate and the bottom plate are independently machined; a machined surface of the foundation plate and the machined surface of the bottom plate are oppositely buckled, clamped and fixed, and after circle centers are determined or position lines of concentric circular holes are marked out on the foundation plate according to the positions of the kidney-shaped holes in the bottom plate, paired marking and disassembling are carried out; the circular holes are drilled in the foundation plate; and during construction site mounting, the bottom plate and the foundation plate are mounted according to paired marking. According to the manufacturing method of the kidney-shaped holes in the sliding support bottom plate of the power station deaerator, machined surfaces of kidney-shaped hole sets are changed into numerical control gas cut surfaces, and corresponding independent machining of the kidney-shaped hole sets and circular hole sets of the foundation plate is changed into matched machining.

Owner:HARBIN BOILER

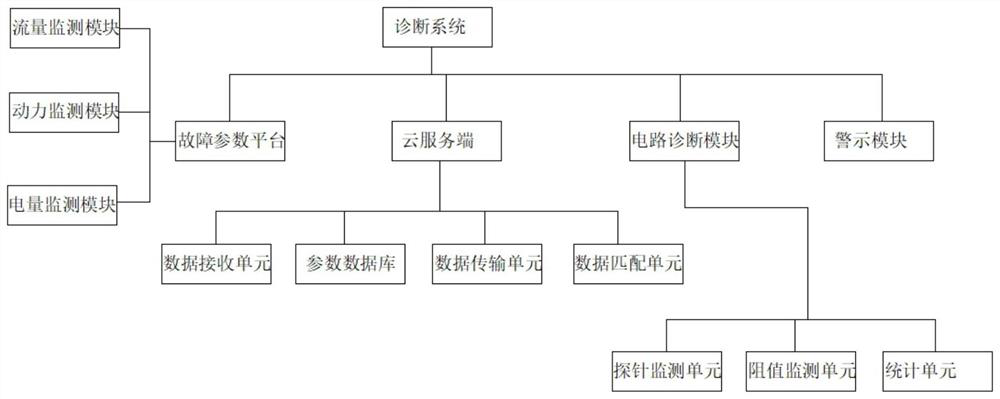

Plunger pump fault diagnosis method and diagnosis system

PendingCN113123958AIncrease credibilityReduce the impactPump testingPositive-displacement liquid enginesControl engineeringTime-sharing

The invention discloses a plunger pump fault diagnosis method and diagnosis system. A diagnosis system is included and comprises a fault parameter platform, a cloud server, a circuit diagnosis module and a warning module, and the fault parameter platform provides information storing fault parameters and provides a function of changing equipment parameters; the cloud server is used for summarizing and storing the fault parameters and realizing online real-time sharing; the circuit diagnosis module is in contact with an electricity measuring instrument to eliminate measurement circuit faults; and according to instrument fault diagnosis, interconnection and intercommunication of monitoring and tracking, online monitoring, predictive maintenance, fault early warning, diagnosis and repair, operation optimization and remote upgrading are carried out on automatic hardware, instruments, sensors and controllers, and the fault parameter platform, the cloud server, the circuit diagnosis module and the warning module are communicated with one another. An intelligent detection method is adopted, the diagnosis efficiency is greatly improved, equipment maintenance is facilitated, and the method is relatively practical.

Owner:XUZHOU XINDALONG CHEM PUMP MFG CO LTD

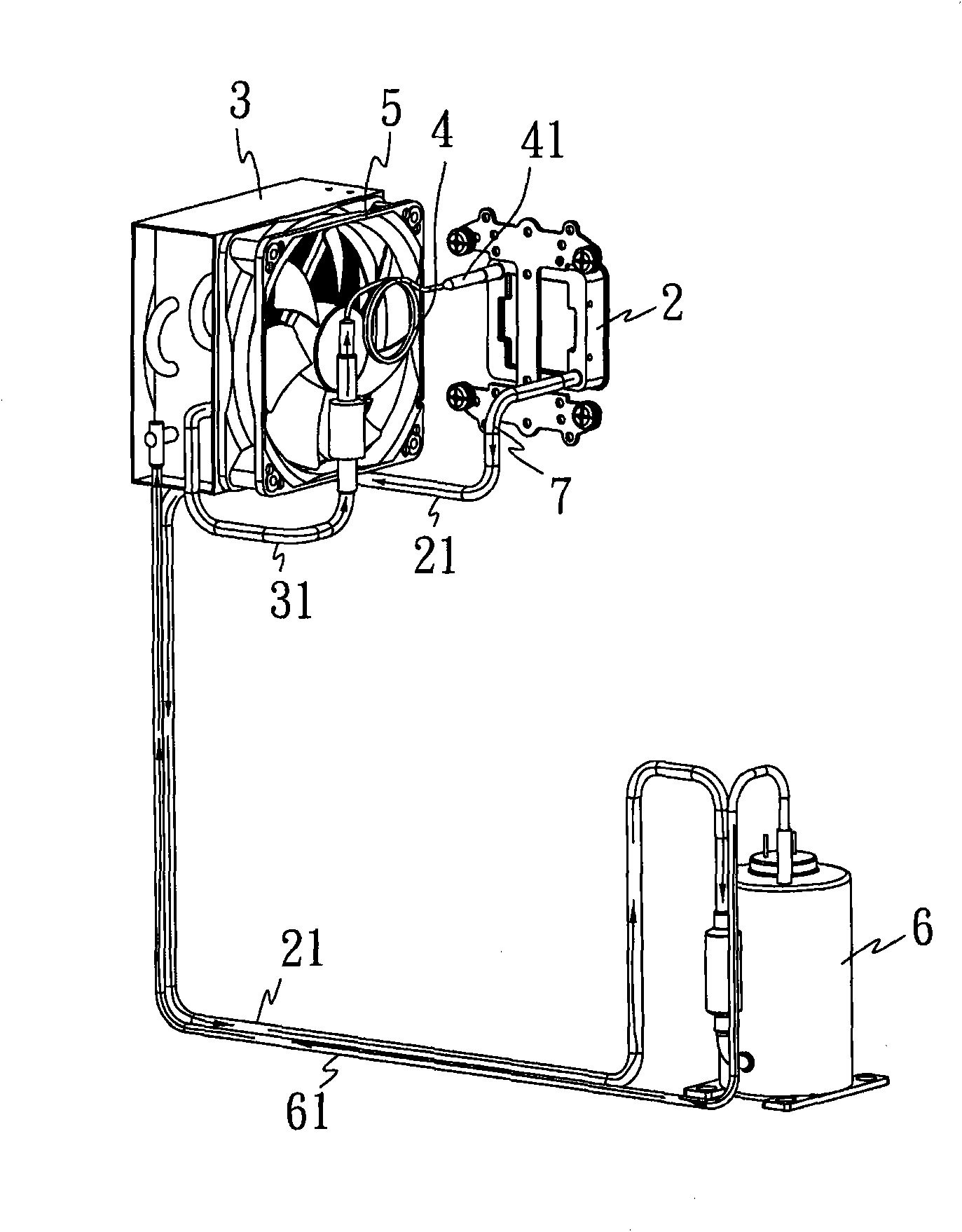

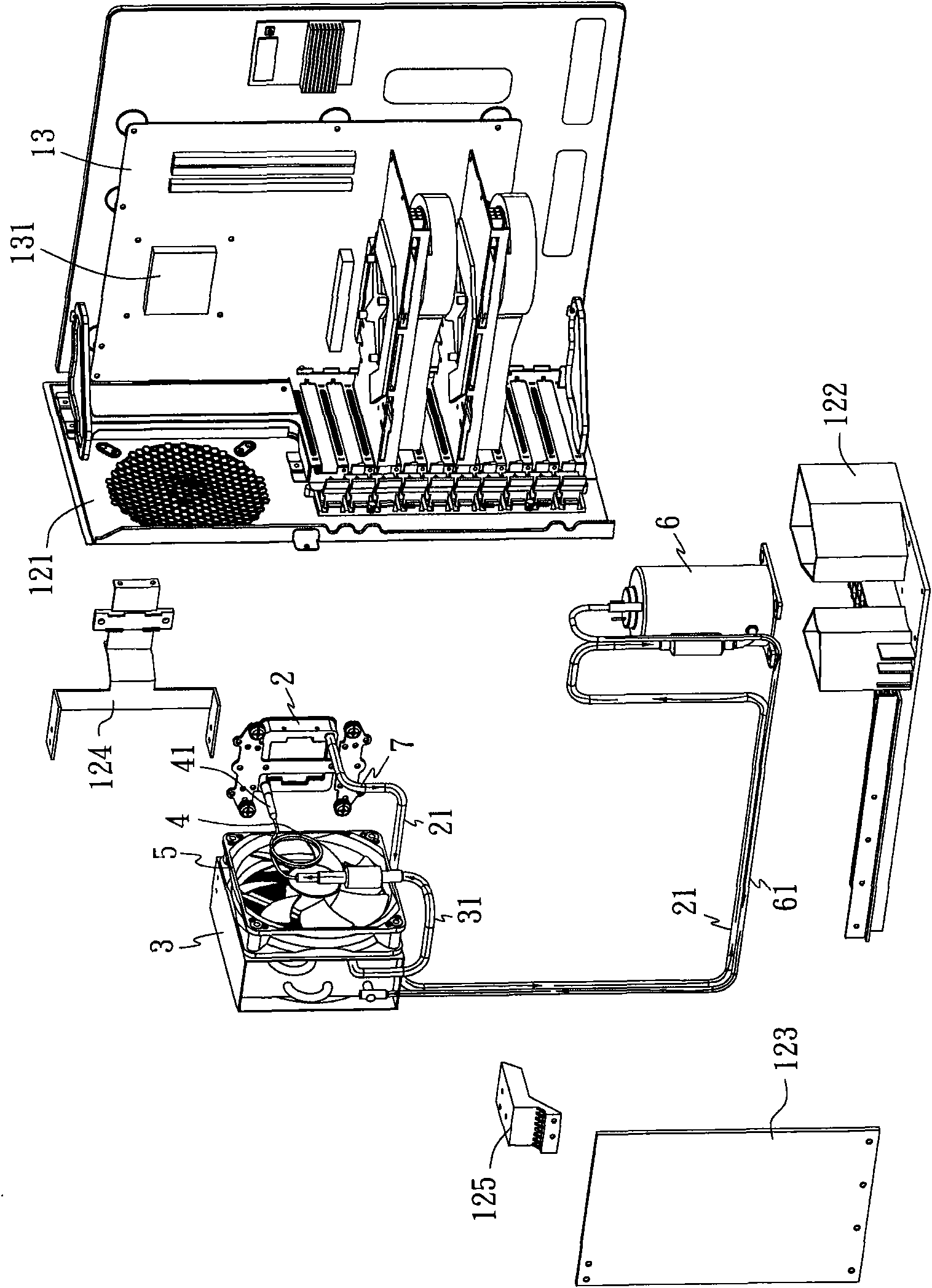

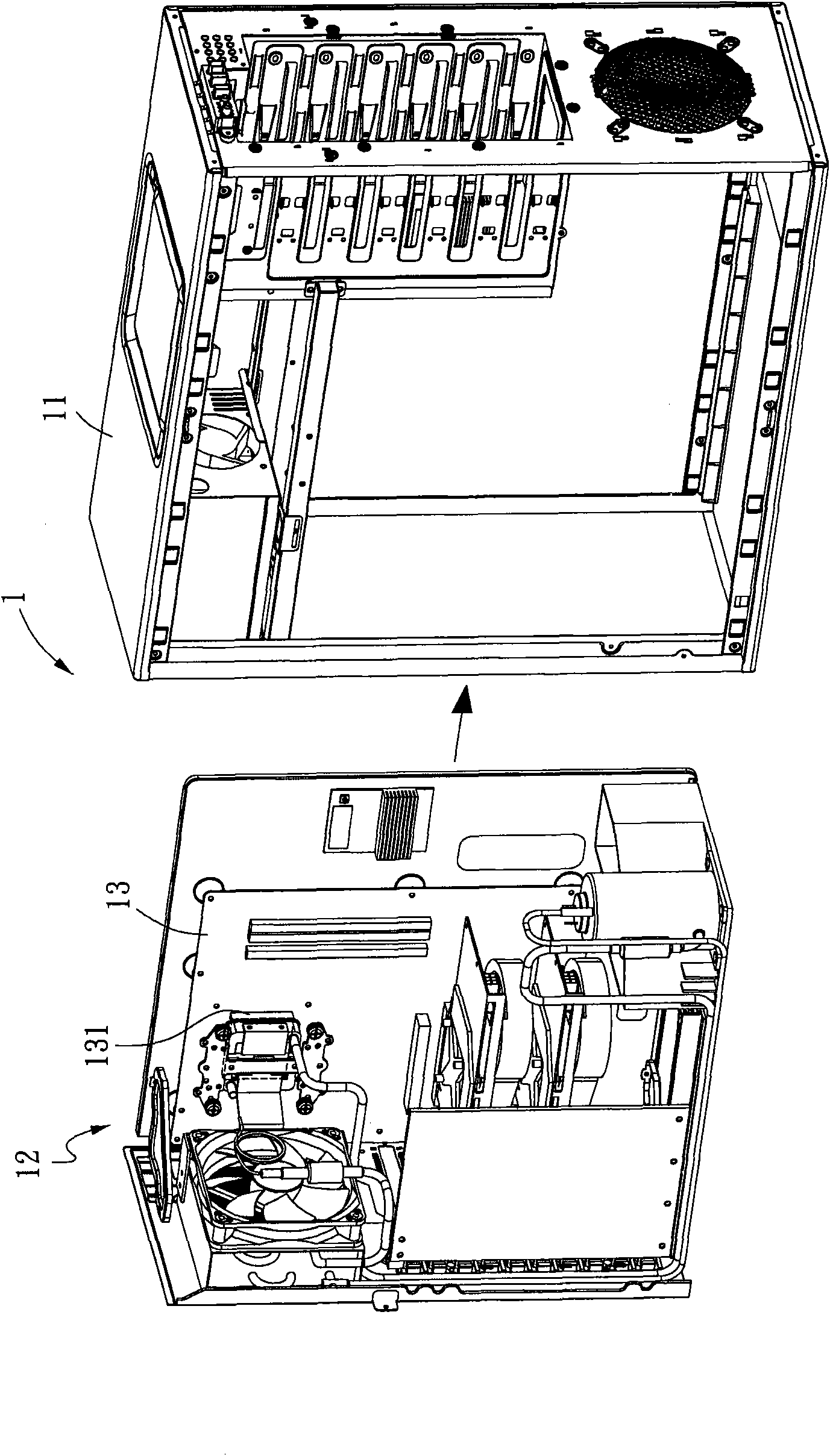

Improved computer cooling device

ActiveCN101561702AImprove shortcomingsFast dissipationDigital data processing detailsCompression machines with non-reversible cycleComputer coolingComputer engineering

The invention discloses an improved computer cooling device which comprises at least one evaporator, a compressor, a condenser, an expanding valve, a fan and a cooling medium. The evaporator is arranged on one side of at least one heating source which is arranged in a computer host unit and can be a central processing unit; the compressor is connected with the evaporator; the condenser is connected with the compressor; the expanding valve is connected between the condenser and the evaporator; the fan is arranged on one side of the condenser; and the cooling medium is circulated among the evaporator, the compressor, the condenser and the expanding valve. Therefore, the invention enables the heating source in the computer host unit to achieve the efficacy of rapid heating source dissipation by utilizing the cooperation of the evaporator, the compressor, the condenser, the fan, the expanding valve and the cooling medium.

Owner:THERMALTAKE

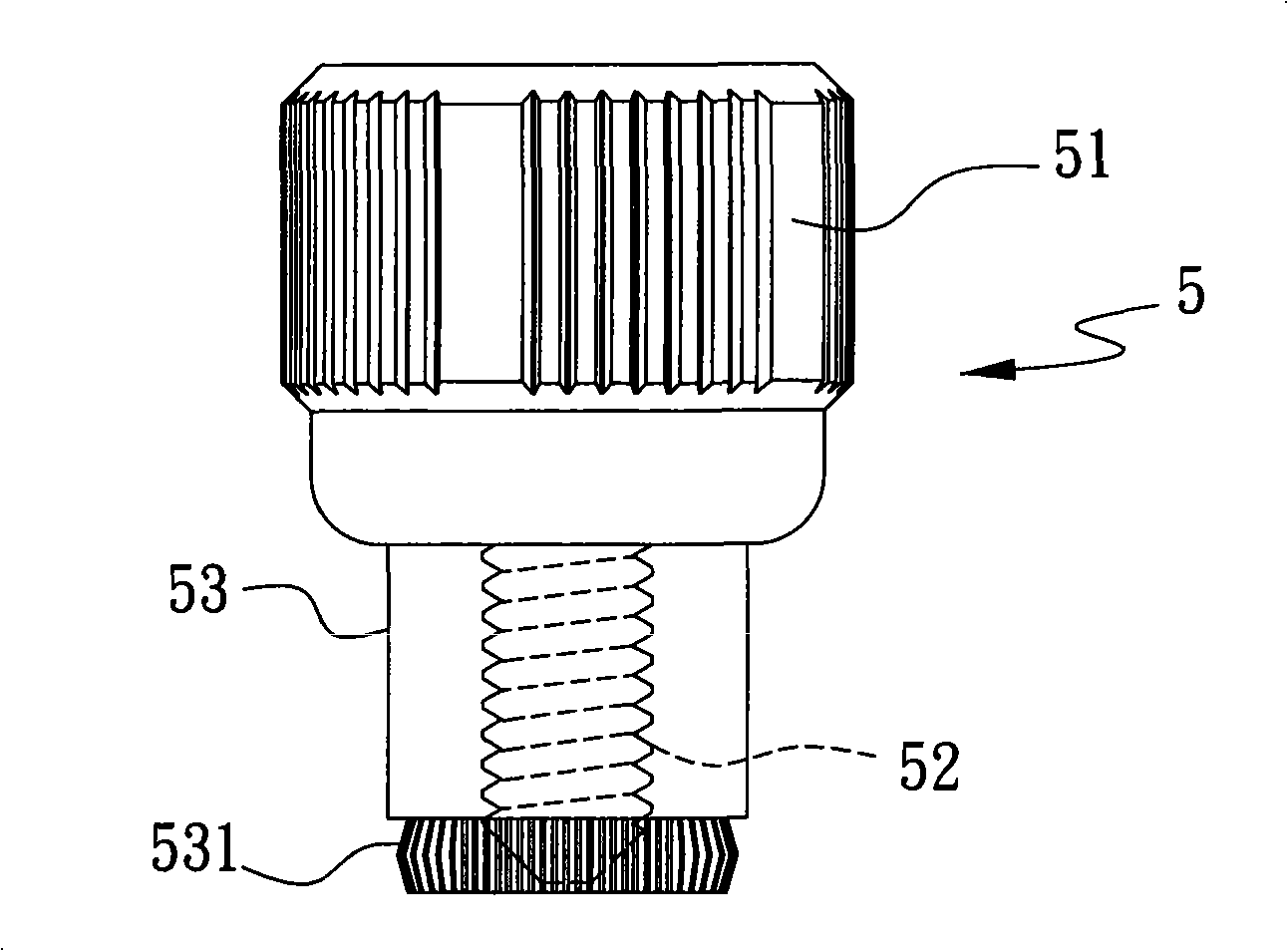

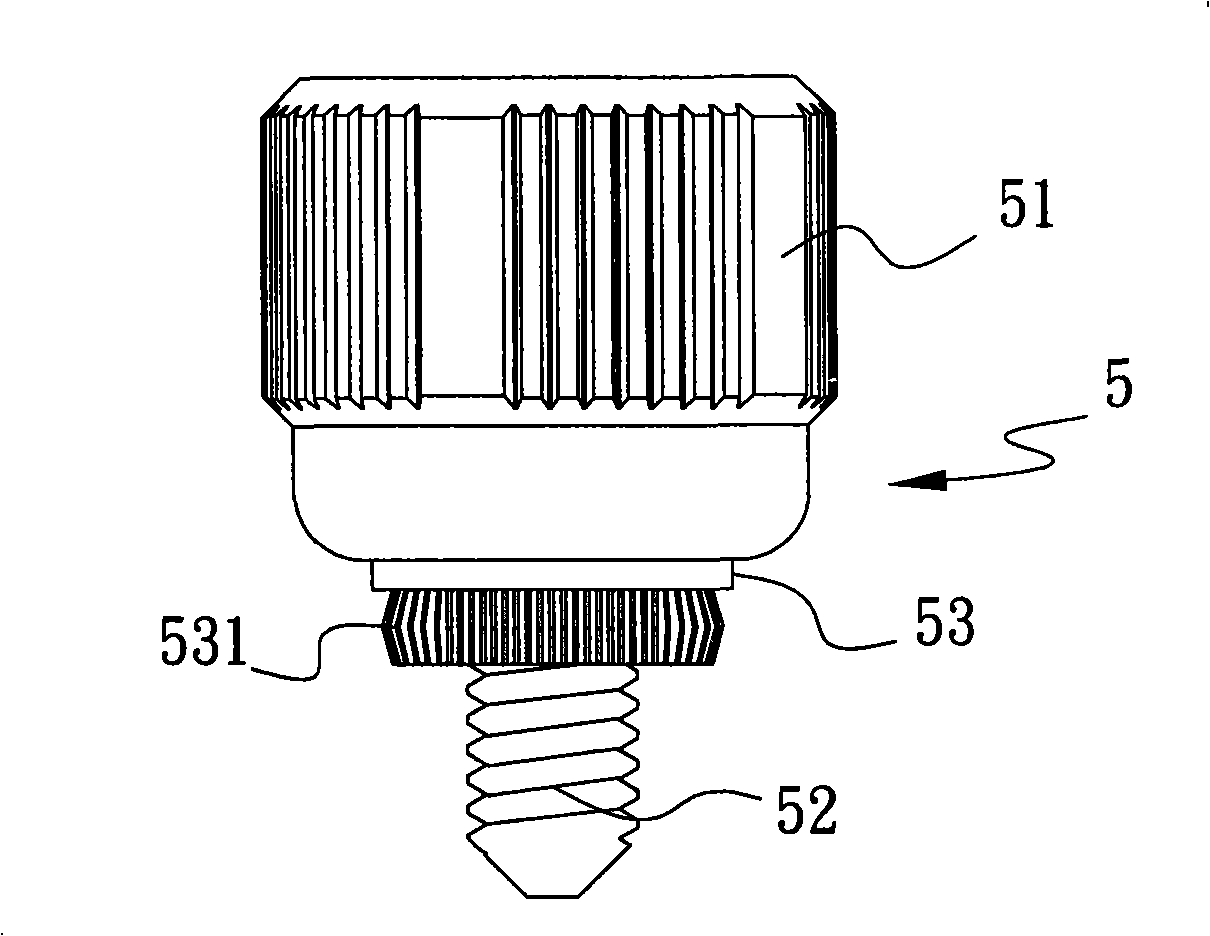

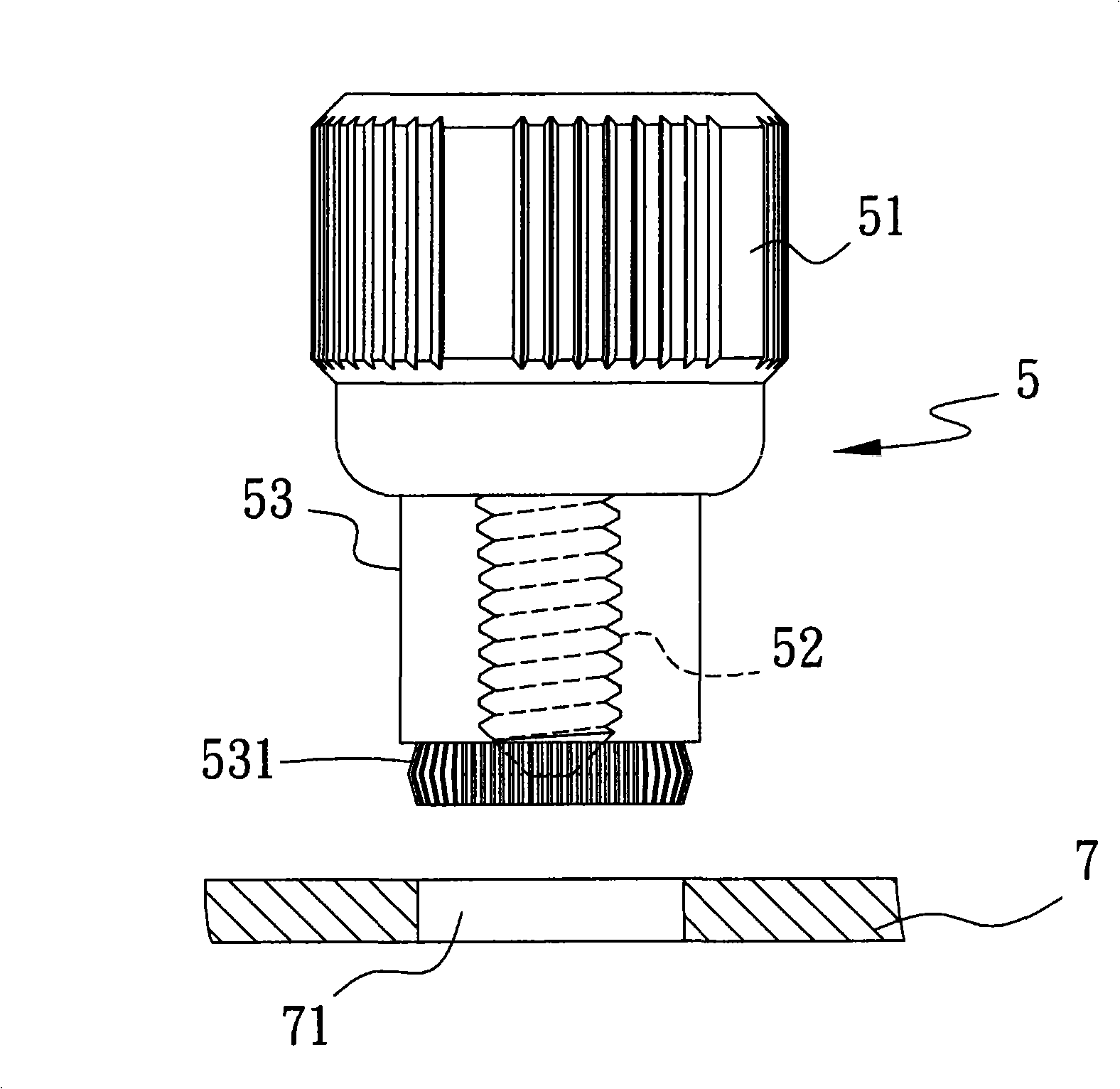

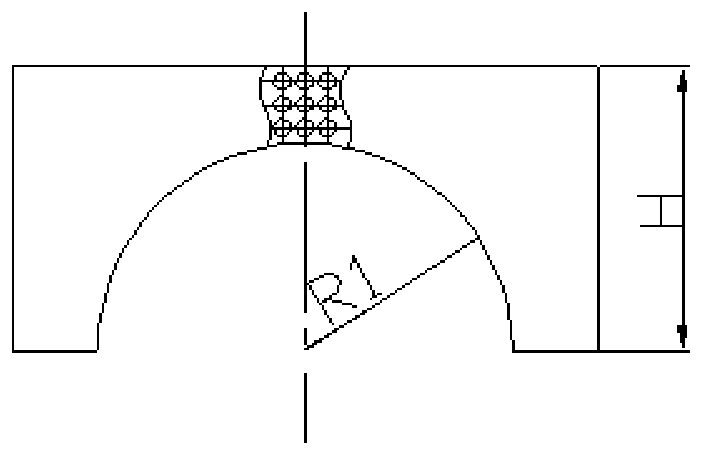

Packaging method for combining screw to printed circuit board

ActiveCN101516163AImprove the various shortcomingsMeet needsPrinted circuit manufacturePrinted circuit non-printed electric components associationPrinted circuit boardScrew head

The invention relates to a packaging method for combining a screw to a printed circuit board, which is a method for combining the screw to the printed circuit board by a surface adhesion technique and comprises the following steps: providing a screw having a screw head, a screw rod extending out of one end of the screw head, and a sleeve sleeved on the periphery of the screw rod and movably arranged on one end face of the screw head; sleeving a limit ring on the screw rod to lean against one end of the sleeve so that part of the sleeve is limited in the screw head; arranging an adhesive layer on the other end face of the screw head; providing the printed circuit board with a plurality of through holes and arranging a soldering tin layer; making a tool use the screw through the adhesive layer and moving the tool so that the screw rod corresponds to the through holes; making the tool release the screw to drop the screw, and arranging a flange of the sleeve in the through holes; heating the soldering tin layer to melt tin, and cooling the soldering tin layer to the normal temperature so as to harden the soldering tin layer; fixedly arranging the sleeve in the through holes; and removing the limit ring. The method has the efficacy of achieving precise, non-offset, non-deflective and easy arrangement in the process of arranging a screw sleeve.

Owner:DTECH PRECISION INDS

Synthesis tower supporting cylinder and manufacturing method thereof

ActiveCN110142008ANew technologyReduce consumption rateChemical/physical/physico-chemical stationary reactorsMaterial consumptionSyngas

Owner:HARBIN BOILER

Method for preparing nutrient enrichment dried beancurd sticks from selenium-enriched tea scraps

InactiveCN109430423AMaintain the traditional production processTraditional production processCheese manufactureFood scienceUltrasonic assistedDietary fiber

The invention relates to a method for preparing nutrient enrichment dried beancurd sticks from selenium-enriched tea scraps. The method mainly comprises the steps of crushing the selenium-enriched teascraps, performing extraction by ultrasonic-assisted hot water extraction method, and performing vacuum concentration to obtain a selenium-enriched tea extraction solution; and peeling soybeans, performing soaking, performing grinding to obtain pulp, cooking the pulp, mixing the cooked pulp with the selenium-enriched tea extraction solution and a modifier in proportion, then performing uncoveringto obtain dried beancurd stick semi-finished products, and performing baking to obtain the nutrient enrichment dried beancurd sticks. The technical method provided by the invention has the characteristics of being low in production cost, simple, convenient and easy to operate; and the selenium-enriched tea scraps are subjected to high-value utilization, bioactive components of organic selenium, tea polyphenols and dietary fibers in the dried beancurd stick are strengthened, the prepared nutrient enrichment dried beancurd sticks concurrently have good mouth feel and the characteristics of health-care foods, and the method can be applied to production of high-grade nutrient enrichment dried beancurd sticks.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

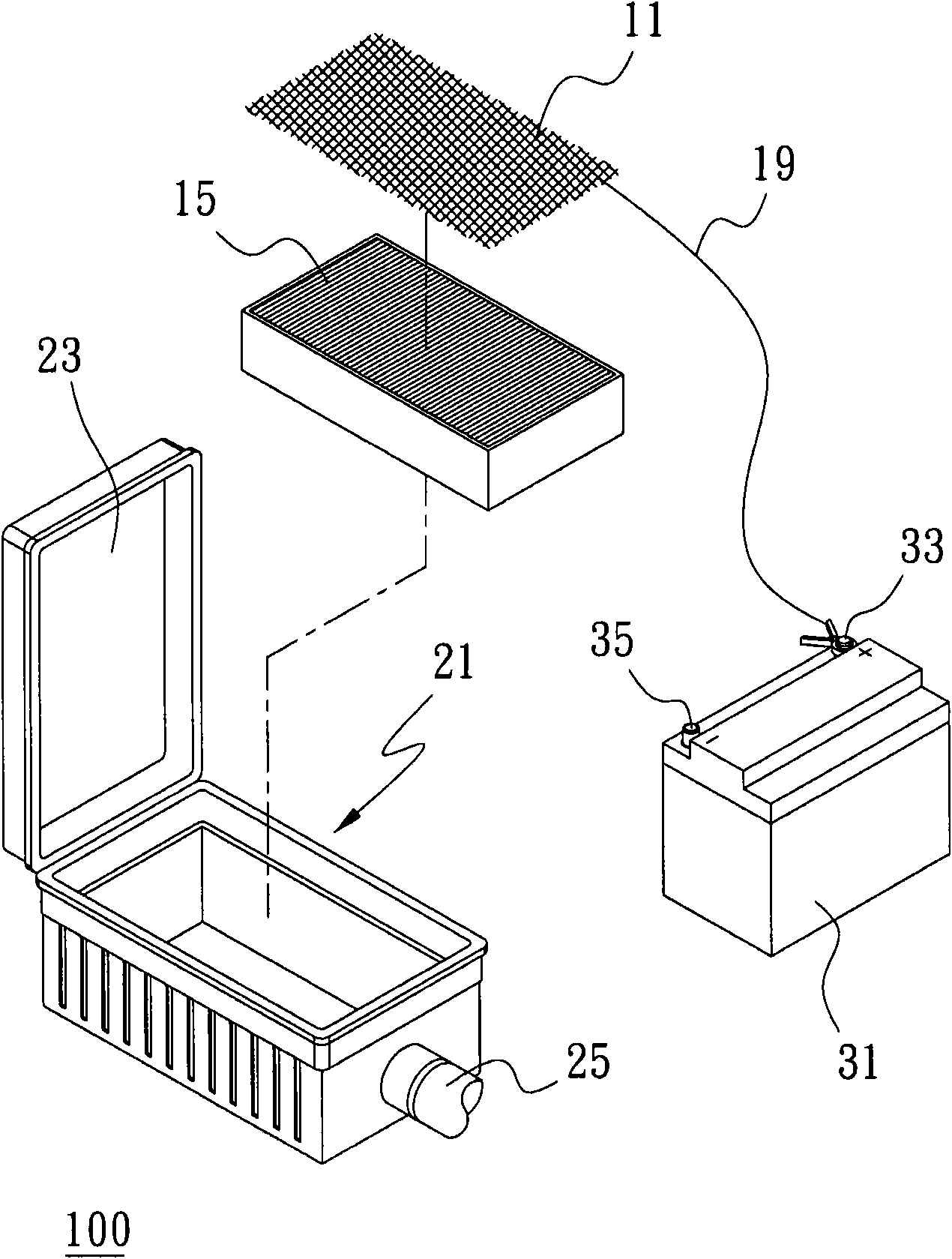

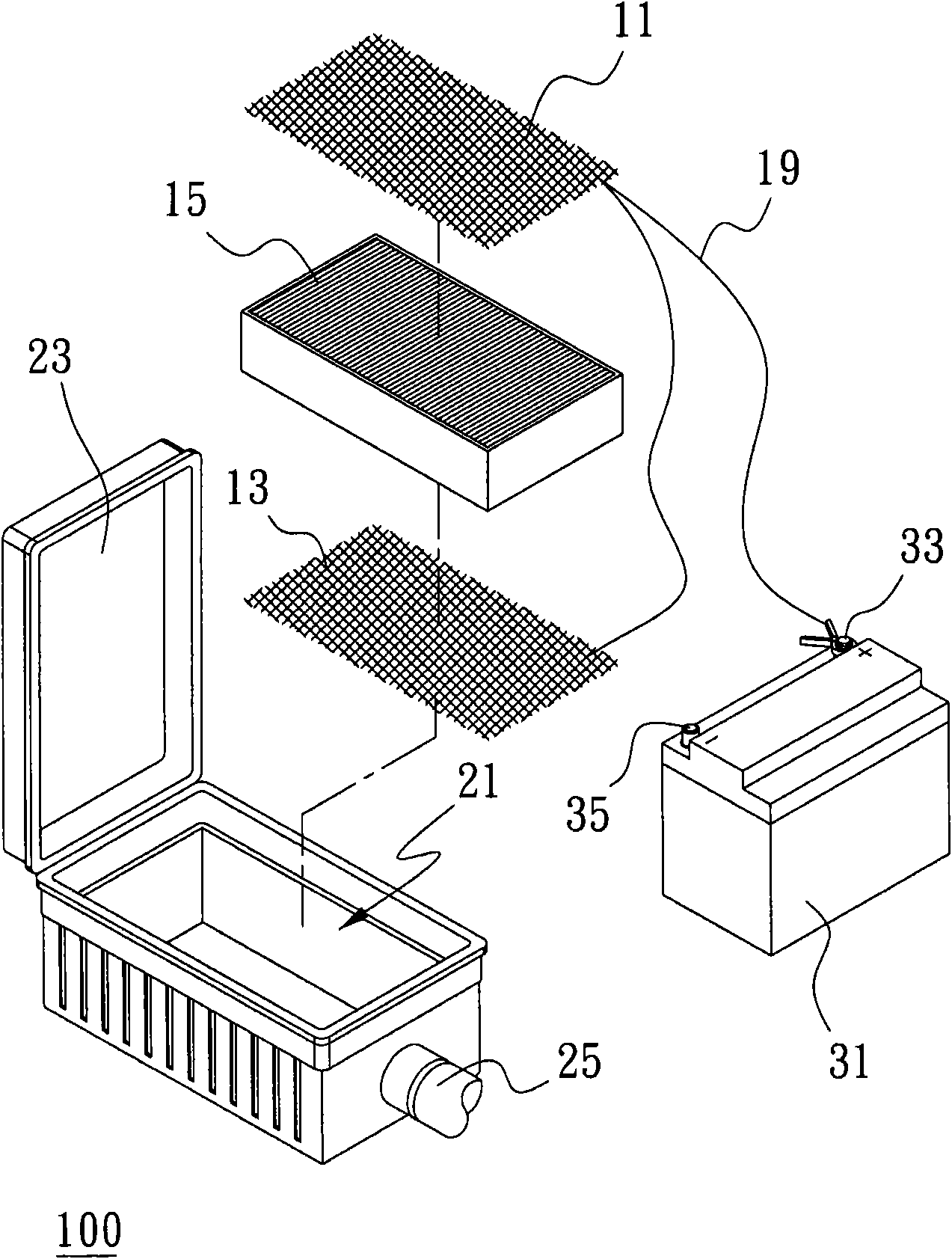

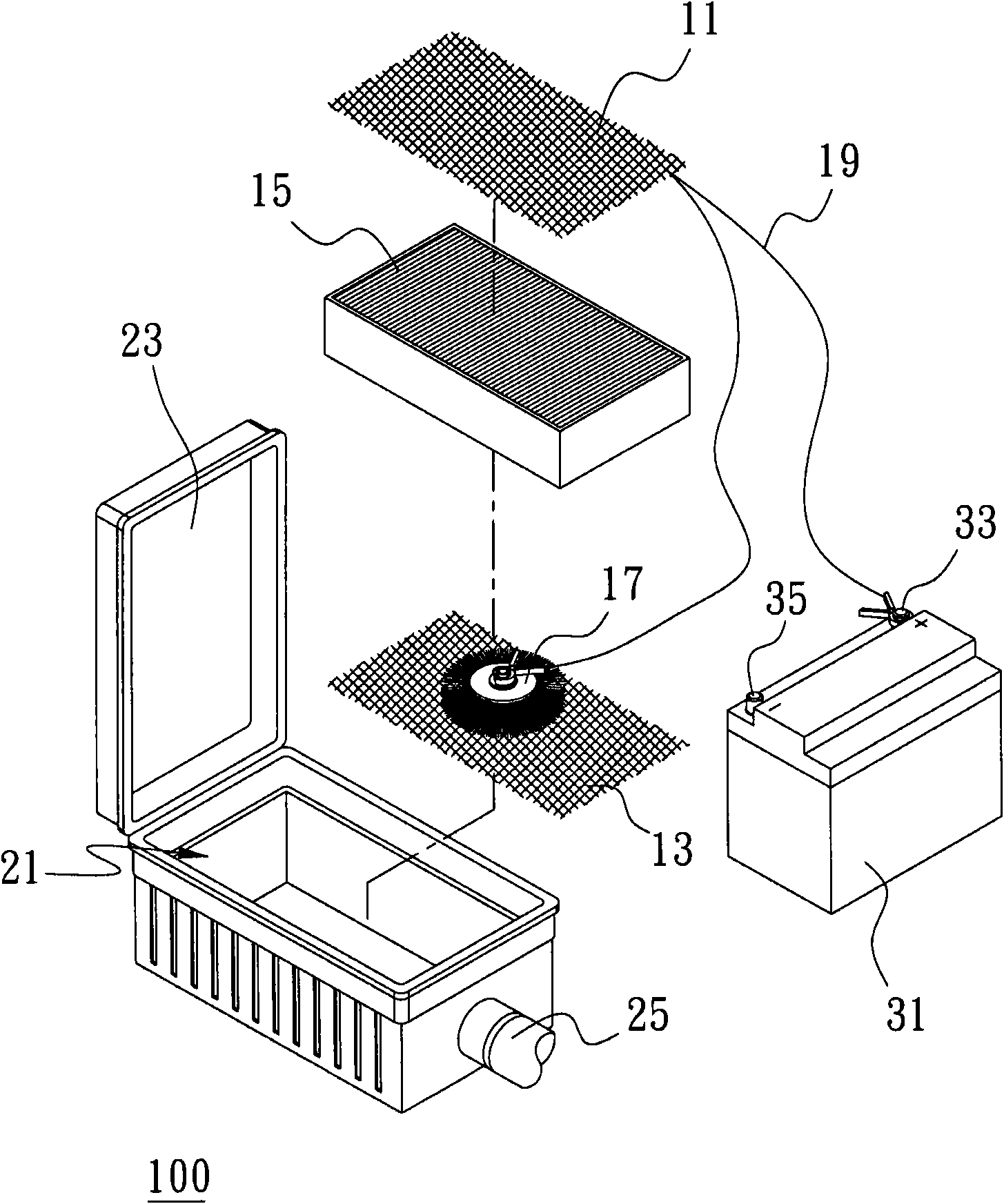

Air activation auxiliary device

InactiveCN101655055AImprove the activation effectMeet the efficacyInternal combustion piston enginesCombustion-air/fuel-air treatmentAir filtrationElectrical conductor

The invention relates to an air activation auxiliary device, which comprises a first far-infrared ray network layer, an air filtration layer, and a first electrical conductor, wherein the first far-infrared ray network layer is made of metal and is used for sending far-infrared rays to activate air molecules; the air filtration layer is used for filtering impurities in the air; the first electrical conductor is connected with a power supply device and the first far-infrared ray network layer; and the first far-infrared ray network layer is not contacted with the air filtration layer. Therefore, the air activation auxiliary device makes the far-infrared ray network layer which is made of the metal connect the power supply device through the first electrical conductor by using a simple component combination so as to generate a magnetic field to strengthen the activation efficiency of the far-infrared ray network layer, so that a user can simply add the air activation auxiliary device without changing the design of an original air inlet system to achieve the aims of low cost, convenient installation and high efficiency.

Owner:刘府广

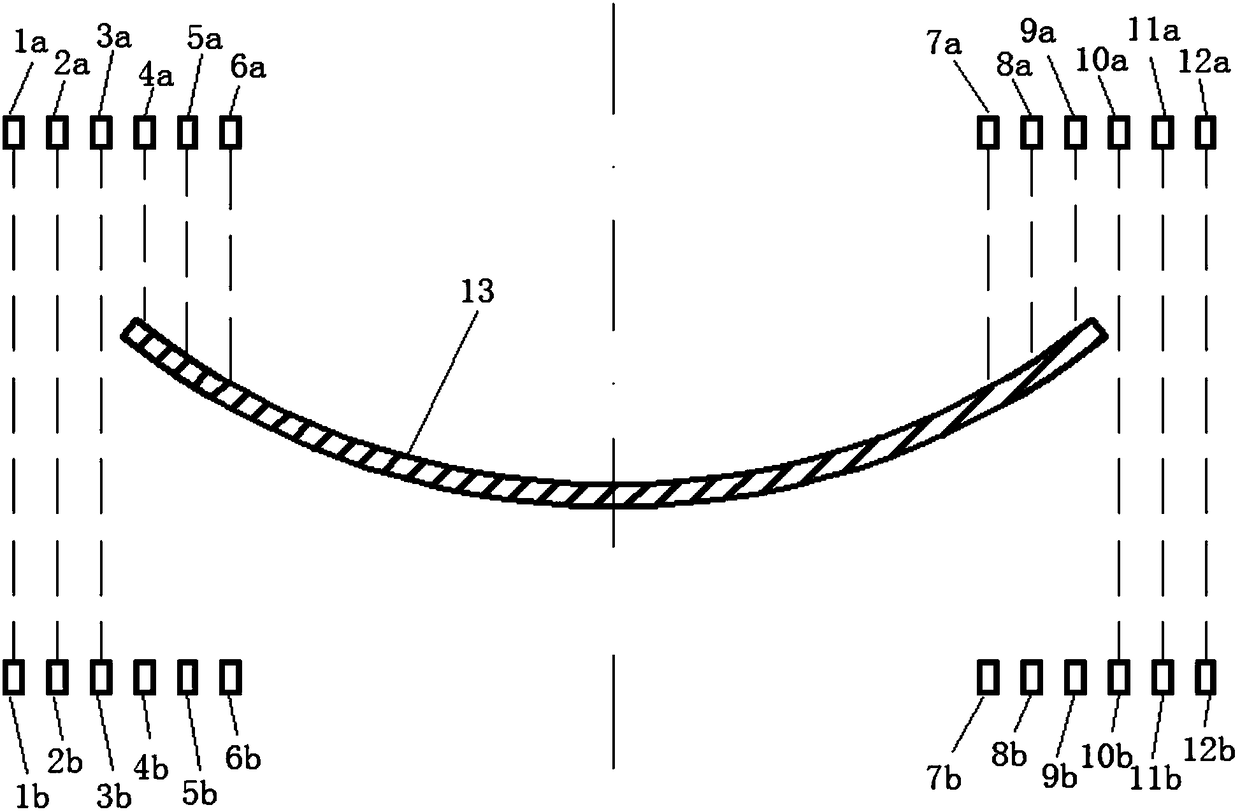

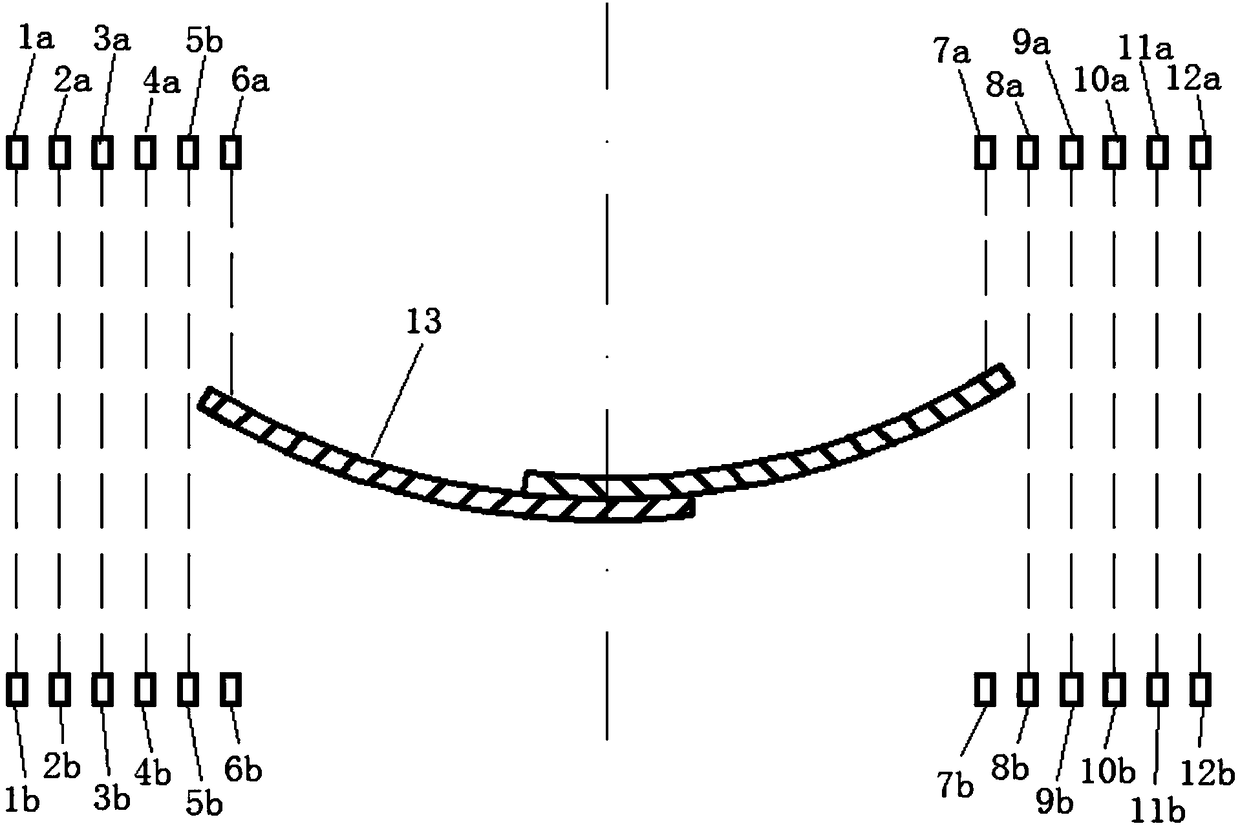

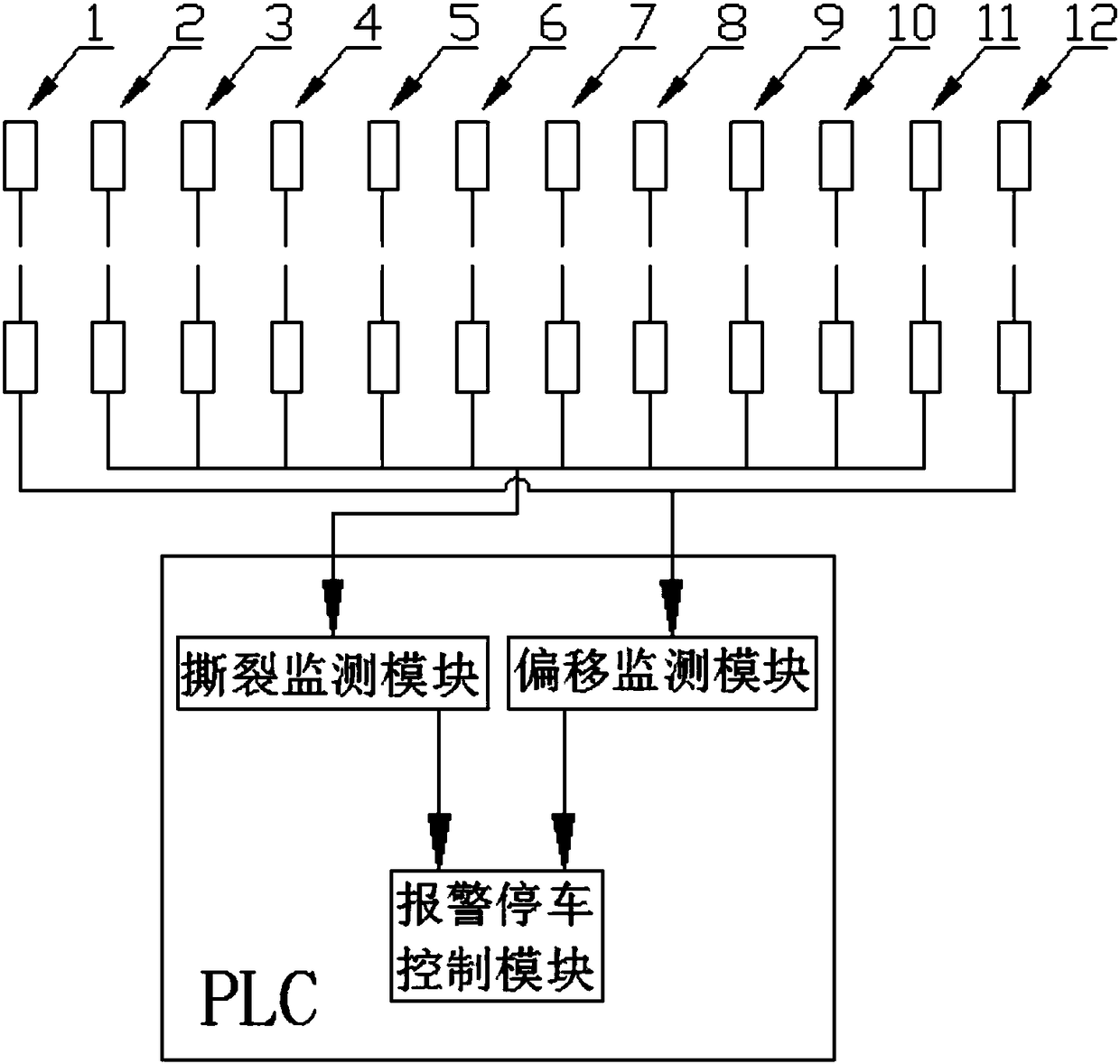

A monitoring system for longitudinal tearing and deviation of steel cord belt conveyor

InactiveCN106429300BStop in timeReduce accident lossesControl devices for conveyorsLaser transmitterProgrammable logic controller

The invention provides a longitudinal tearing and deflecting monitoring system for a steel wire core rubber belt machine. The longitudinal tearing and deflecting monitoring system comprises a PLC (Programmable Logic Controller) and multiple groups of opposite-type laser monitoring devices; laser emitters of the opposite-type laser monitoring devices are fixed above the rubber belt machine along the width direction of the rubber belt machine in a mode of being symmetrical about the central axis of the rubber belt machine; laser receivers are fixed right below the rubber belt machine in a mode of being symmetrical to the laser emitters and are located between an upper rubber belt and a lower rubber belt; the PLC comprises a deflection monitoring module, a tearing monitoring module and an alarming and halting module; at least two groups of opposite-type laser monitoring devices on the outermost side of the two sides of the opposite-type laser monitoring devices communicate with the deflection monitoring module, and the other opposite-type laser monitoring devices communicate with the tearing monitoring module; and the deflection monitoring module and the tearing monitoring module separately communicate with the alarming and halting module. According to match pairing of the plurality of opposite-type laser monitoring devices, belt width change is monitored in real time as a criterion, and timely alarming and halting for a longitudinal tearing accident of the rubber belt machine are finished by utilizing the PLC.

Owner:ANHUI UNIV OF SCI & TECH

A method for controlling natural fruit setting of Kyoho grapes

InactiveCN105993823BQuality improvementReduce management costsFertilising methodsCultivating equipmentsFruit setNutrition

The invention provides a method for controlling natural fruit setting of Kyoho grapes. The method comprises the steps of perfecting rain shelter infrastructure construction, managing a fertilizer and water, enhancing nutrition supply of tree bodies, reapplying an organic fertilizer, strictly controlling a nitrogenous fertilizer, applying a phosphate fertilizer and a potash fertilizer, supplementing calcium, magnesium and boron micro-element fertilizers and strengthening prevention and control of diseases and insect pests, ensuring normal fruit setting, controlling the treetops and hastening blossom before flowering, improving the nutrition absorption capacity of fruit clusters and conducting effective fruit cluster management in the flowering and fruit setting periods. According to the method for controlling natural fruit setting of the Kyoho grapes, by means of artificial measures, the nutrient-flow dynamic balance regulation and control function of the Kyoho grape tree bodies is stimulated, the fruit dropping speed is accurately controlled, the optimal time point of fruit setting is mastered in time, uniform fruit dropping is guaranteed, and fructification is controlled accurately; the fruit product quality is vigorously improved on the basis of ensuring the normal yield, and the labor cost for fruit thinning can be greatly reduced.

Owner:邓万良

Preparation method of biomedical high-purity magnesium tube rod wire raw material

ActiveCN114653776AAchieve continuous cumulative plastic deformationImprove plastic deformation abilityProcess engineeringApparatus instruments

The invention discloses a preparation method of a biomedical high-purity magnesium tube rod wire raw material, which comprises the following steps: firstly, manufacturing a semi-finished product of a tube rod wire by adopting a warm-state large-deformation extrusion technology, and then preparing a deep-processed product of the tube rod wire by adopting a cold-state small-deformation rotary swaging technology. And finally, performing post-treatment to prepare the finished product raw material of the tube-rod wire for the medical apparatus and instruments, which can meet different purposes. The preparation method has the characteristics of feasibility, practical processing technology, relatively low production cost and the like.

Owner:JINAN UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com