Electrolyte barrel cleaning method

A technology for cleaning electrolytes and barrels, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of difficult maintenance and low equipment costs, and achieves reduction of manual labor intensity and equipment costs. The effect of reducing and saving solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

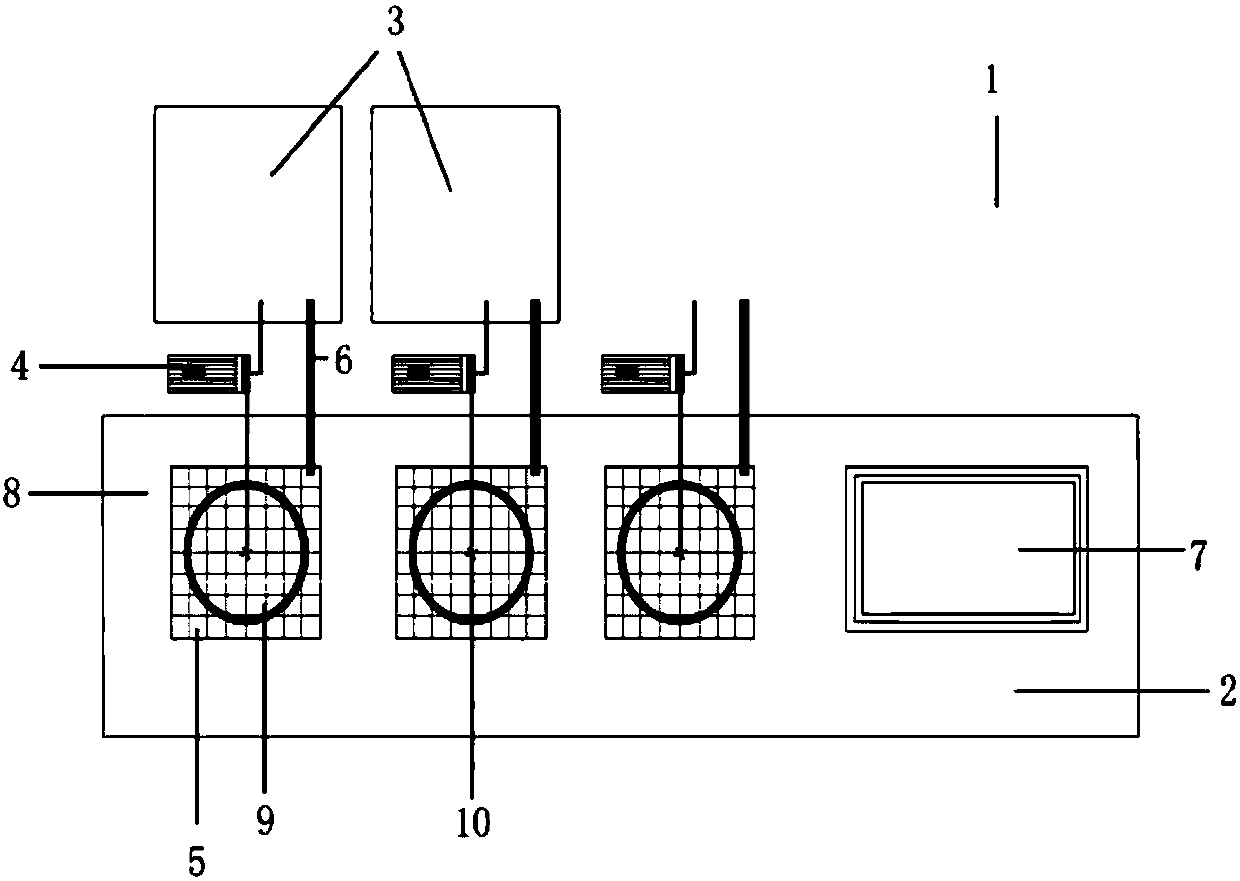

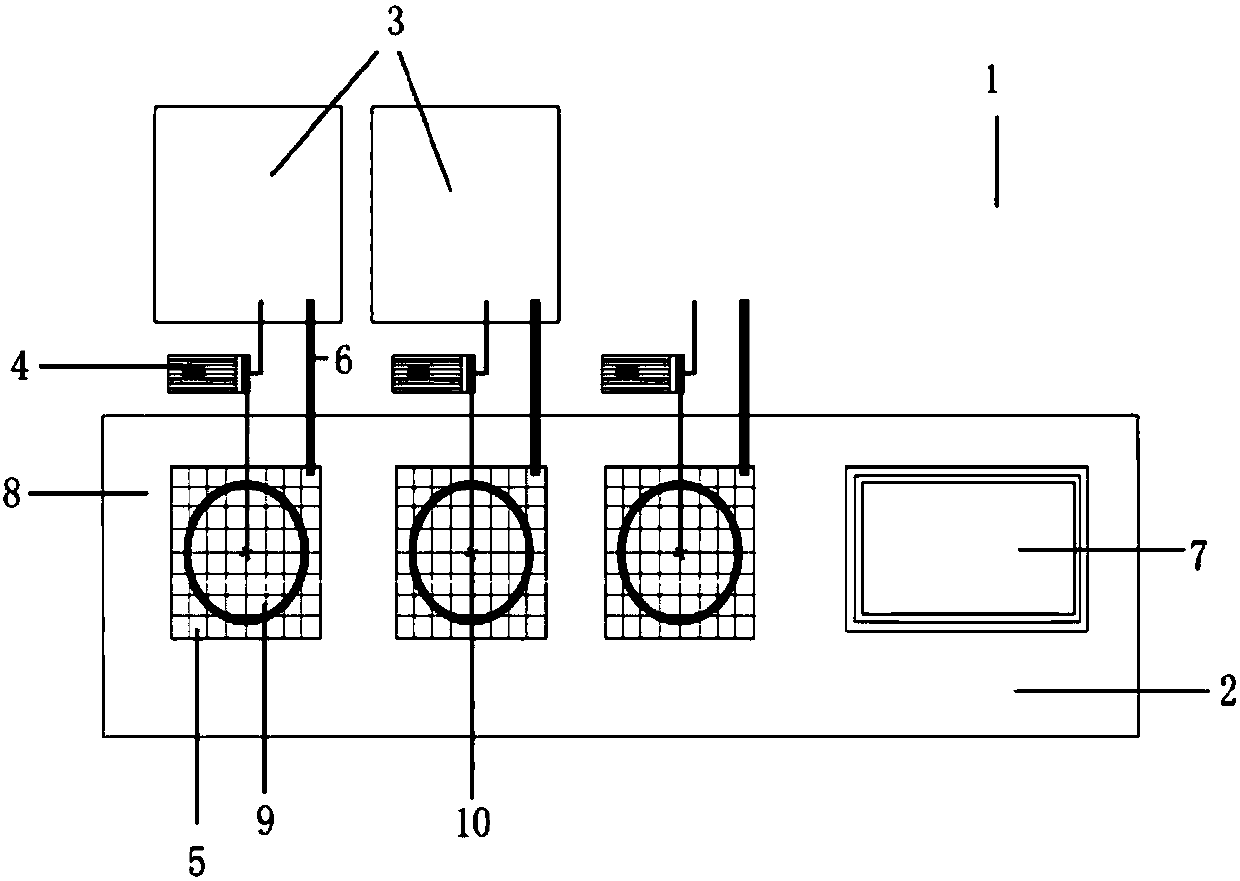

[0031] In the embodiment of the present invention, the oxalic acid liquid washing process is as follows: the electrolyte barrel is placed upside down in a fixed position in the pickling area, the oxalic acid liquid is extracted from the oxalic acid liquid storage tank through the automatic booster pump 4, and transported to the pickling area through pipelines 9 fixed position, sprayed from the automatic rotating nozzle of the water outlet structure 10 in the pickling area 9 to spray the inside of the electrolyte cylinder, after the spray washing is completed, the spray liquid can be discharged through the hollow drainage structure 5 set up in the pickling area 9 for pickling Area;

[0032] Preferably, the spraying liquid discharged through the hollow drainage structure 5 is separated into recyclable oxalic acid solution and spraying wastewater, and the recyclable oxalic acid solution is recycled to the oxalic acid storage tank, and the spraying wastewater can pass through the h...

Embodiment 2

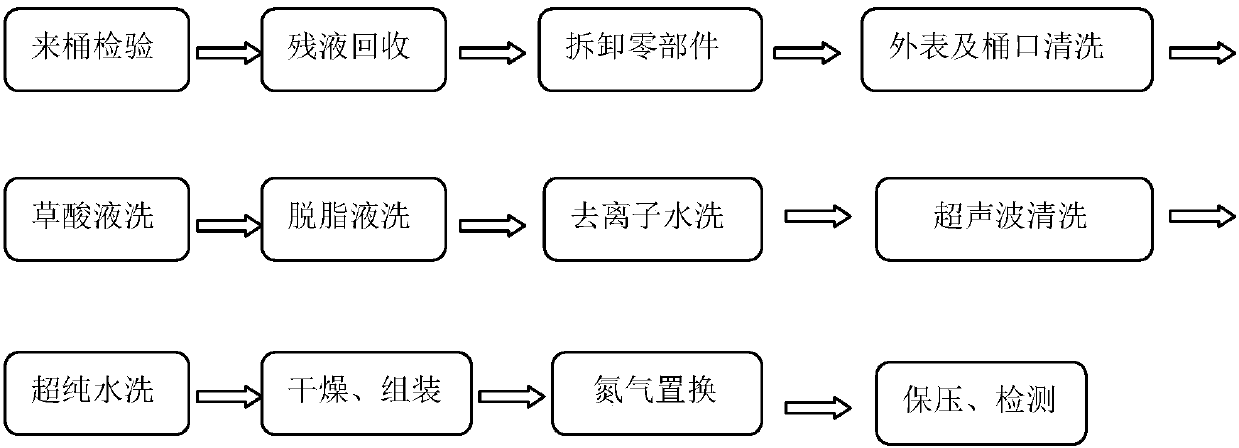

[0059] Such as figure 2 As shown, in the embodiment of the present invention, in the electrolyte barrel cleaning method described above, the electrolyte barrel cleaning process needs to go through incoming barrel inspection, residual liquid recovery, disassembly of parts, parts cleaning, appearance and barrel mouth cleaning, and barrel cleaning. Internal cleaning, drying, assembly, nitrogen replacement, pressure keeping, testing. In the barrel inspection, after the appearance inspection, the barrels that are deformed, damaged, etc. that cannot be used are eliminated, and the electrolyte barrels that meet the secondary use are left in place, and the residual liquid is recovered, and the remaining electrolyte barrels that meet the secondary use are recovered. And remove the pressure in the barrel. For the cleaning of the spare parts, before performing the cleaning process on the electrolyte barrel, the electrolyte barrel needs to be disassembled, and the disassembled spare par...

Embodiment 3

[0062] In the implementation of the present invention, the cleaning process in the electrolyte barrel includes: oxalic acid solution washing process, degreasing liquid washing process, deionized water washing process, ultrasonic cleaning process, and high-purity water washing process. Among them, the process of oxalic acid liquid washing process, degreasing liquid washing process and deionized water washing process is to extract the cleaning liquid through the automatic booster pump 4, transport it to the fixed position of the pickling area 9 through the pipeline, and discharge the water structure 10 from the pickling area 9 The spraying of the automatic rotating nozzle sprays the inside of the electrolyte cylinder. After the spraying is completed, the spraying liquid can be discharged from the pickling area through the hollow drainage structure 5 set in the pickling area 9; the spraying liquid discharged through the hollow drainage structure 5 is passed through Separation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com