A monitoring system for longitudinal tearing and deviation of steel cord belt conveyor

A technology of longitudinal tearing and monitoring system, which is applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problem of not being able to detect tape tearing in time, and achieve shortened downtime, practical technology, and simple installation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

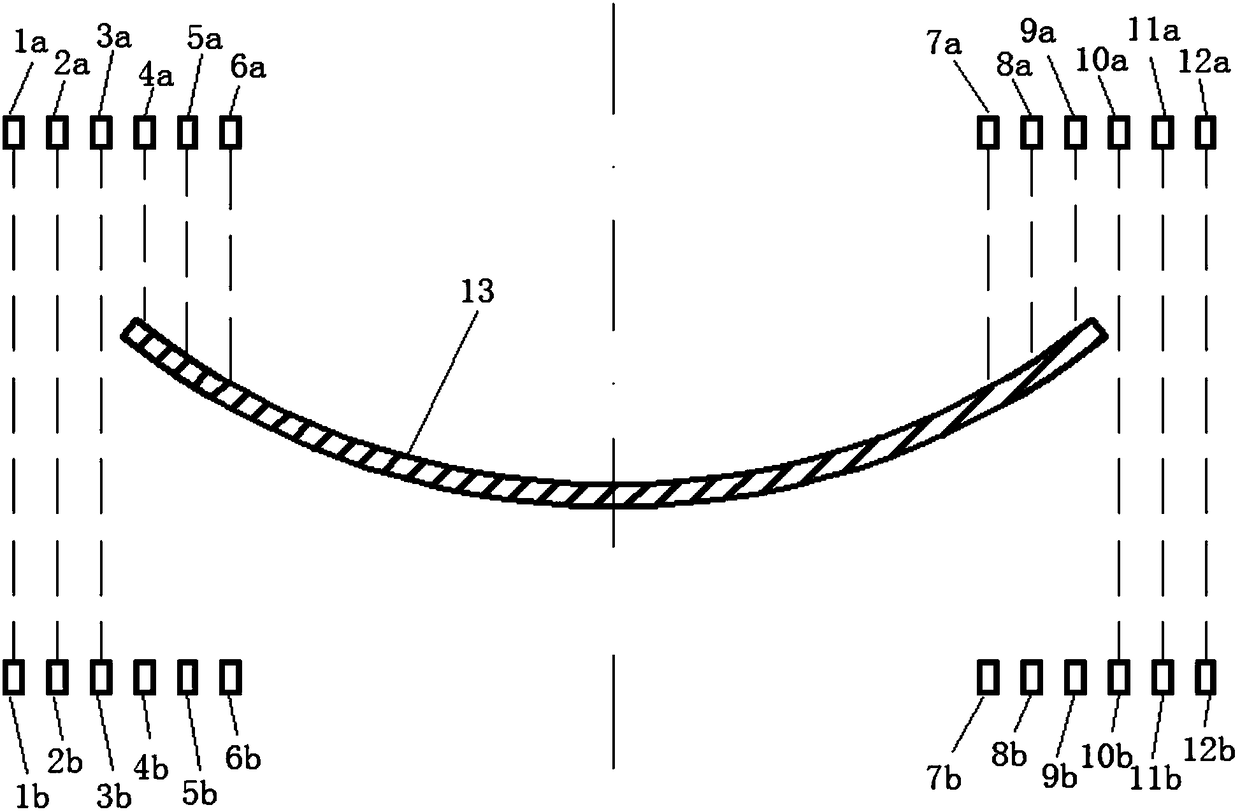

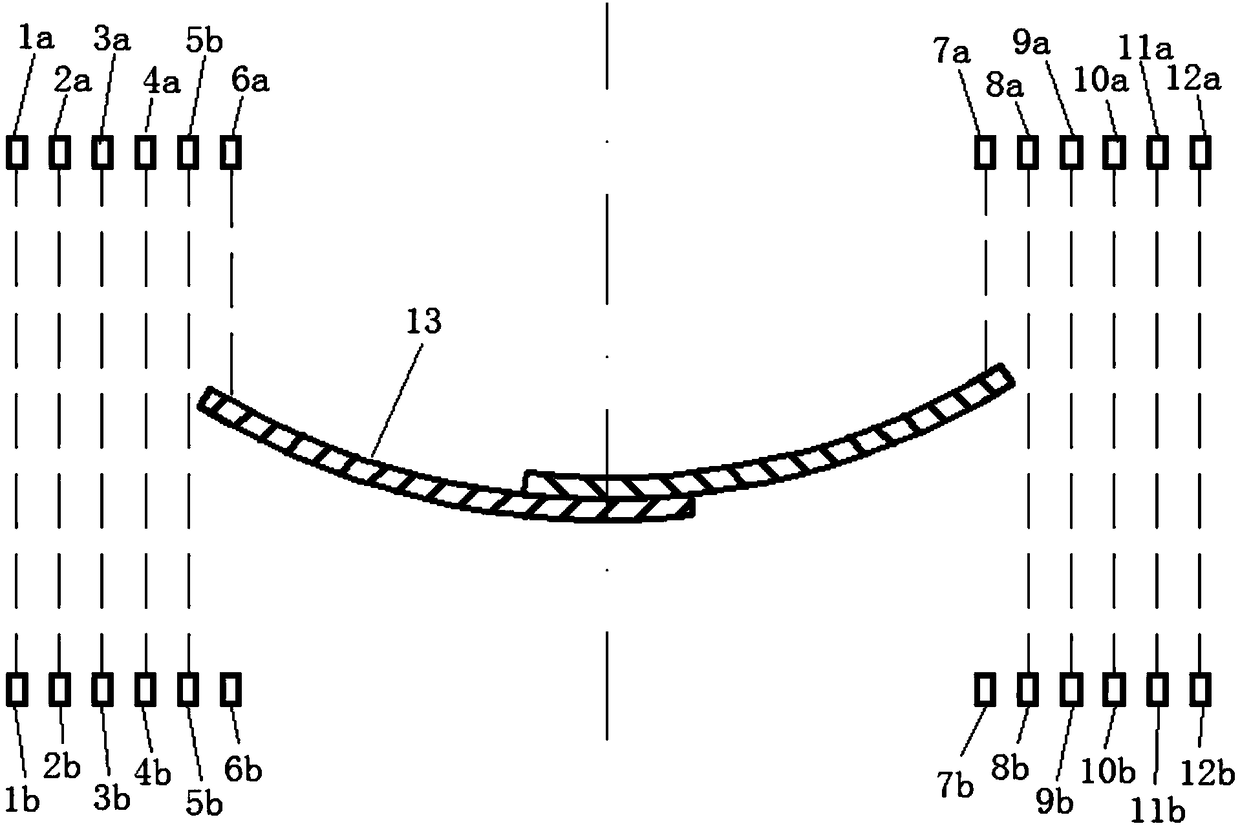

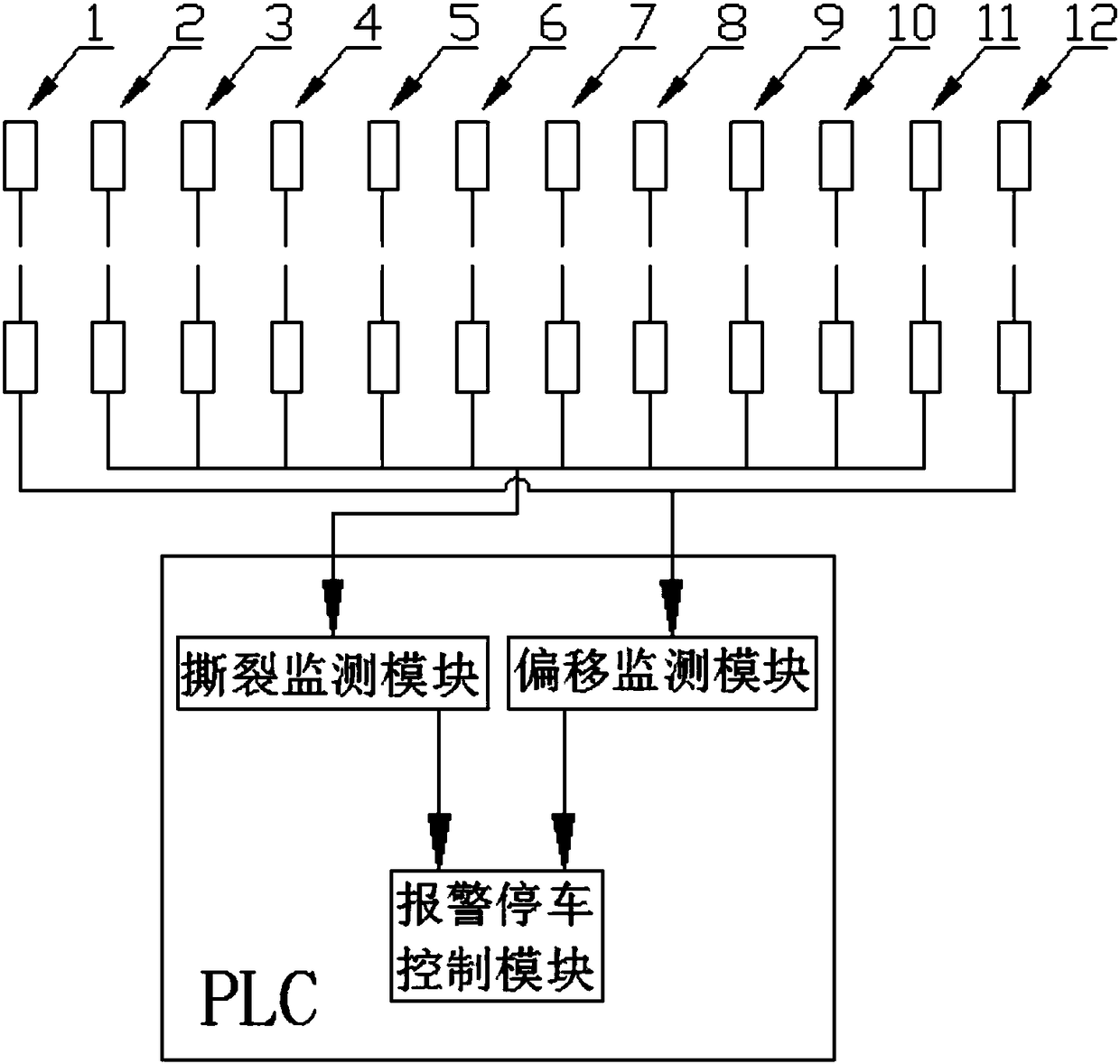

[0029] The number of through-beam laser monitoring devices can be flexibly set according to the width of the tape machine. This embodiment takes 12 groups as an example to describe this scheme in detail:

[0030] Such as figure 1 The 12 groups of through-beam laser monitoring devices are the through-beam laser monitoring devices A1 to L12 arranged sequentially from the upper tape 13 from left to right along the width direction of the upper tape 13 . Among them, the laser emitters are arranged horizontally along the tape and symmetrically with the center line of the tape machine above the tape machine, respectively marked as laser emitter A1a ~ laser emitter L12a, and the corresponding laser receivers are arranged directly below it, located on the upper tape 13 Between them and the lower tape, they are marked as laser receiver A1b ~ laser receiver L12b respectively.

[0031]Wherein the through-beam laser monitoring device A1 to the through-beam laser monitoring device F6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com