Automatic paper-feeding device of hot machine

An automatic, modular machine technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of affecting the production preparation time of operators, large hidden dangers of operation safety, waste of manpower and material resources, etc., to achieve safe operation of employees, high work efficiency, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

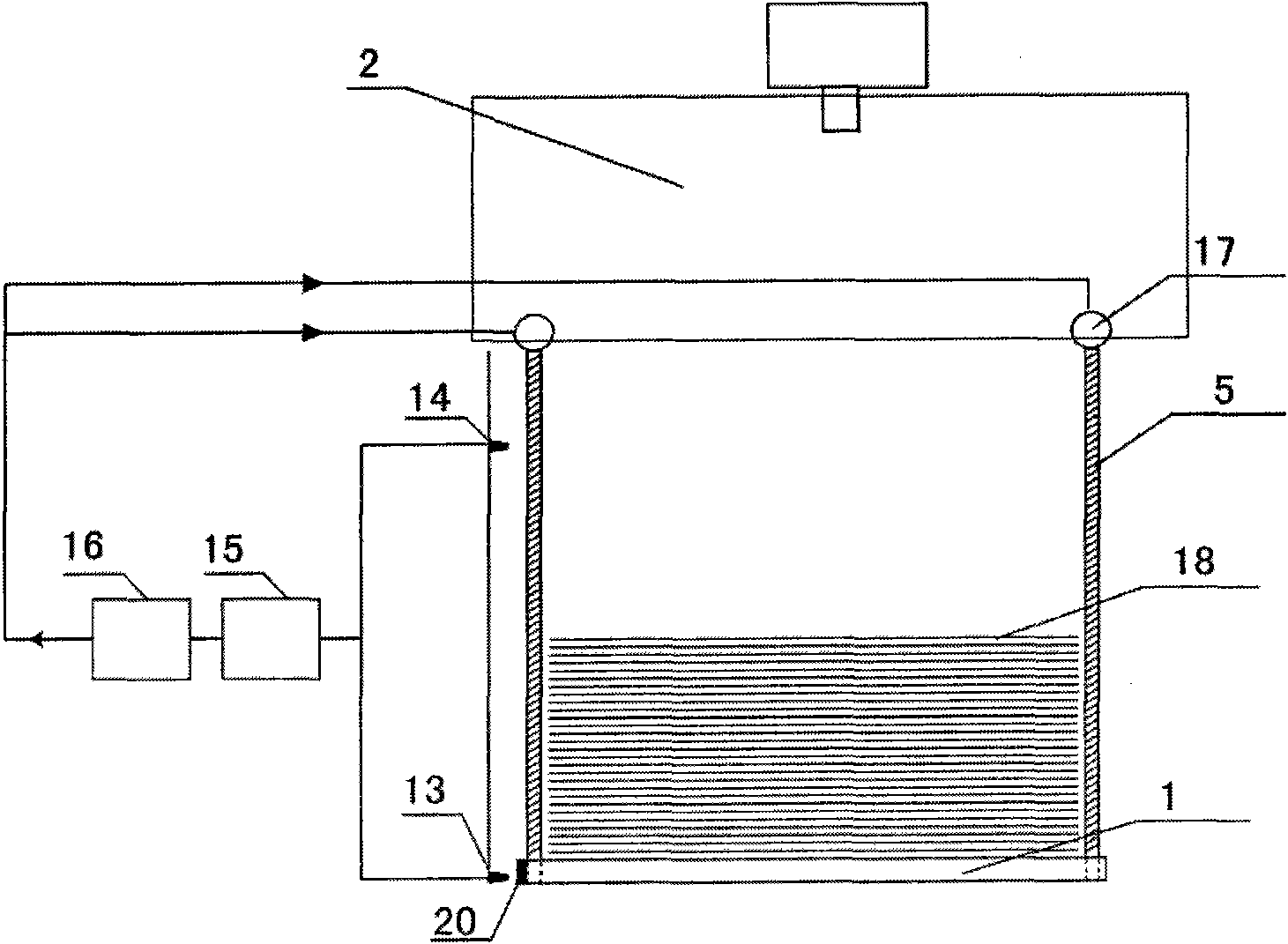

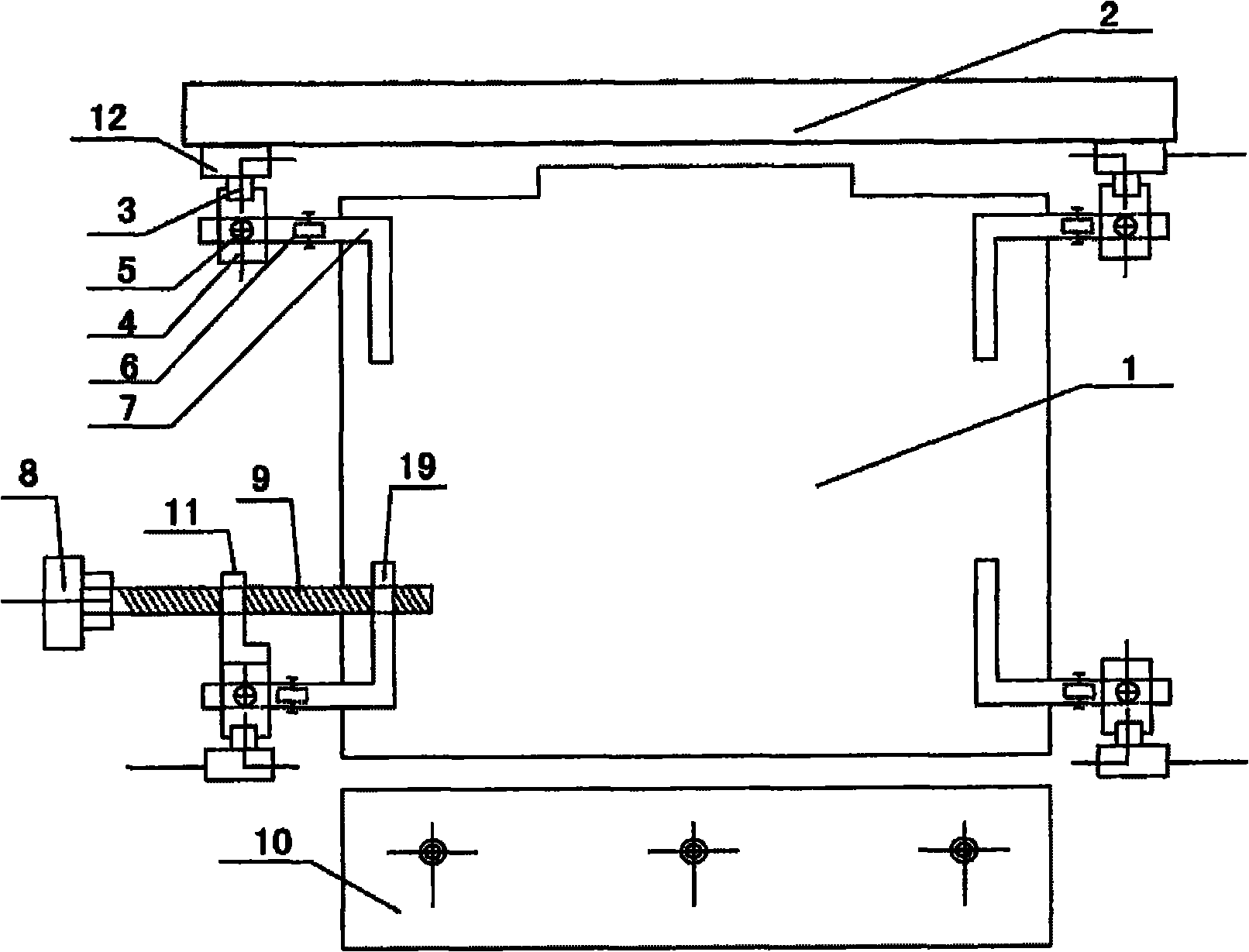

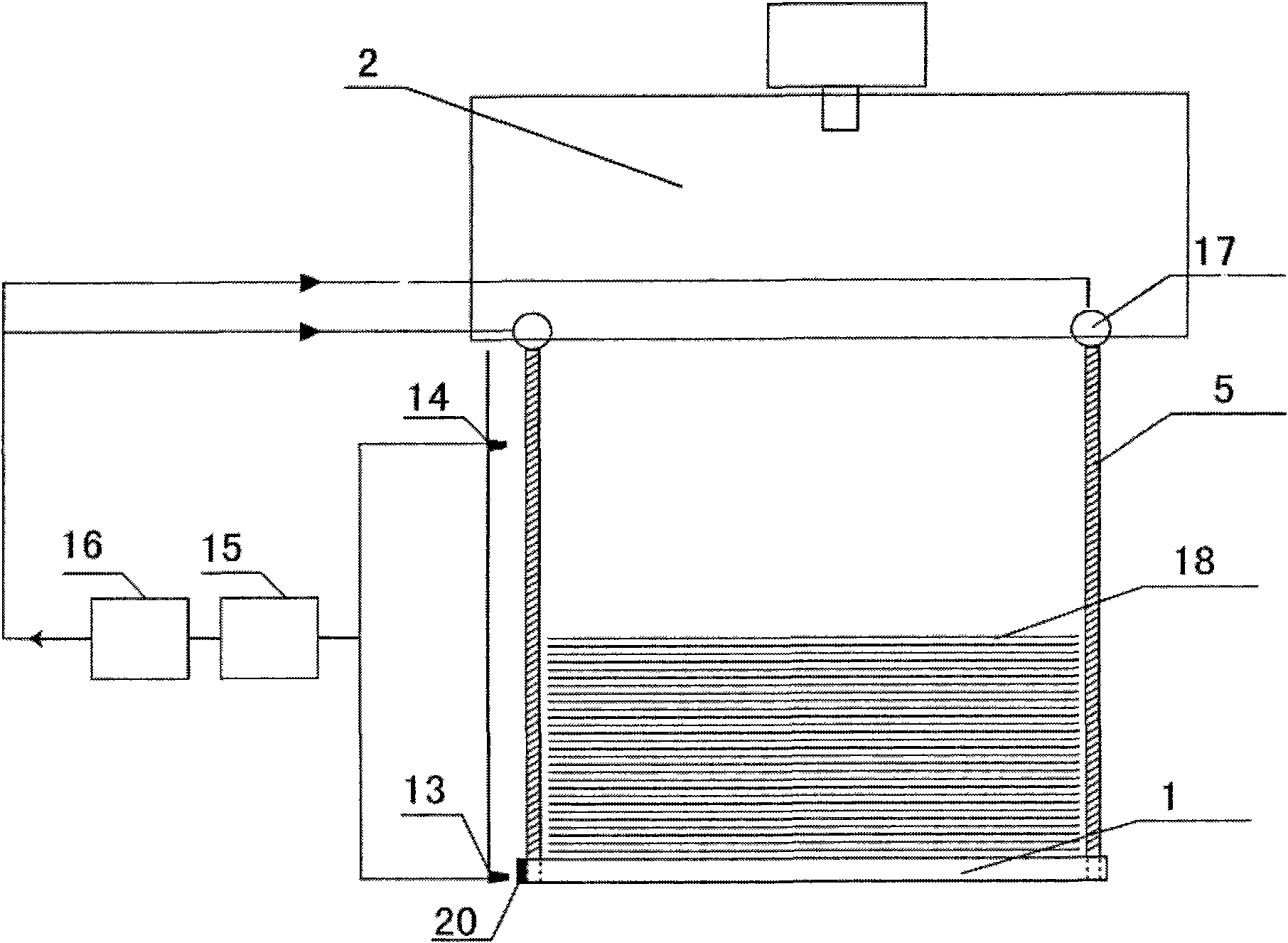

[0012] Such as figure 1 , figure 2 As shown, the four sprockets 17 of the frame 2 are equipped with chains 5, the motor 16 is connected with the sprockets 17, the four corners of the paper lifting bottom plate 1 are connected with four chains 5, and the motor 16 controls the lifting of the paper lifting bottom plate 1 through the chains 5 , the through-beam photoelectric switch 13 and the light control sensor 14 communicate with the motor 16 through the programmable controller 15 respectively, and a reflector 20 is housed on the paper-lifting bottom plate 1, which is opposite to the through-beam photoelectric switch 13; the paper-lifting bottom plate 1 and the belt The connecting plate with the roller 6 is connected to 7, and then connected to the slider 4, the slider 4 is connected to the chain 5, the slider 4 is engaged with the lifting guide rail 3, and is lifted along the lifting guide rail 3, and the lifting guide rail 3 is fixed on the frame 2 on the guide rail support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com