Preparation method of biomedical high-purity magnesium tube rod wire raw material

A pure magnesium tube rod wire, biomedical technology, applied in the field of high-purity magnesium raw material preparation, can solve the problems that affect the mechanical service performance and uniform degradation performance of new medical device products, the microstructure is not uniform, and the processing efficiency is low, so as to reduce the number of times Effects of production-induced defects, reduction of surface oxidation pollution, and scientific preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Select high-purity magnesium ingots with a diameter of 80mm and a length of 150mm customized on the market.

[0034] 2. The above blanks are placed in a common muffle furnace (resistance furnace) for heating, the heating temperature is 250°C, the holding time is 45min, and the furnace is filled with argon for protection to reduce oxidation.

[0035] 3. Place the heated billet in a 200T horizontal extruder for extrusion, the extrusion ratio is 25:1, the processing rate is 96%, the extrusion speed is 10mm / s, and the billet is extruded to the diameter with graphite lubrication. 16mm bar.

[0036]4. Install a sizing die with a diameter of 15mm on the head of the 5.5KW swaging machine (the swaging method adopts a four-way pressure type, each pair of forging dies consists of four petals and is arranged at 90°), After the extruded high-purity magnesium bar is simply trimmed and cut to length, one end of the bar is placed in the special fixture of the rotary forging machine...

Embodiment 2

[0041] 1. Using the method of steps 1-4 in the previous example 1, first prepare a swaging bar with a diameter of 15mm, and then replace it with 14, 13, 12, 11.5, 11, 10.5, 10mm swaging dies of different diameters in turn. Carry out gradual small deformation cold rotary forging. After each pass is processed, the billet is held at a temperature of 150 ° C for 5 minutes, and then the billet is taken out and cooled to room temperature before lower die rotary forging. Repeat this until the final size is reached. It is a 10mm small size high-purity magnesium bar. During the period, the maximum processing rate of each pass is about 15%, and the feeding speed is about 150mm / min.

[0042] 2. The above-mentioned high-purity magnesium rod with a diameter of 10mm is subjected to finished product recrystallization annealing, the temperature is set to 180 ° C, and the temperature is kept for 45 minutes; then the surface of the material is brightened by grinding and polishing processes, and...

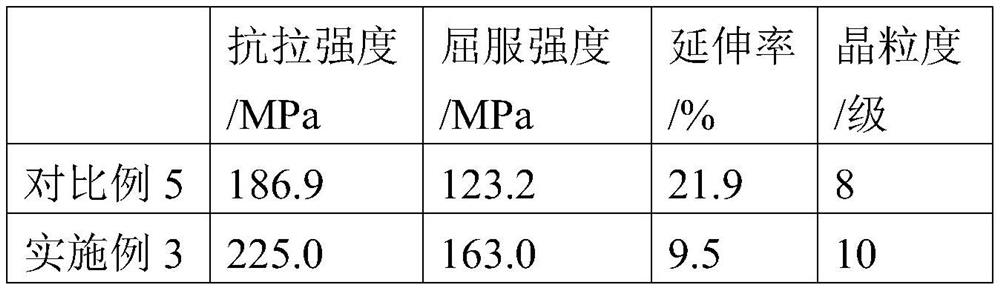

Embodiment 3

[0045] 1. Select high-purity magnesium ingots with a diameter of 48mm and a length of 150mm customized on the market.

[0046] 2. The above blanks are placed in a common muffle furnace (resistance furnace) for heating, the heating temperature is 200°C, the holding time is 60min, and the furnace is filled with argon gas for protection to reduce oxidation.

[0047] 3. The heated billet is placed in a 200T horizontal extruder for extrusion, the extrusion ratio is 25:1, the processing rate is 96%, the extrusion speed is 15mm / s, and the billet is extruded to a diameter with graphite lubrication. 9mm bar.

[0048] 4. Install swivel dies with diameters of 8.5mm and 8.0mm on the head of the 5.5KW swaging machine in turn, and then perform cold swaging with gradual and small deformation respectively. The processing rate of the passes is 10.8%, 11.4 %, the feeding speed was controlled at 150mm / min; between two times of rotary forging, the billet was taken out after being held at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com