Connecting structure for rising cylinder and descending cylinder of gasification furnace and manufacturing method

A connection structure, gasification furnace technology, applied in the direction of manufacturing combustible gas, granular/powdered fuel gasification, petroleum industry, etc. problems such as poor quality and low production efficiency, and achieve the effects of optimizing design structure and manufacturing technology, improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

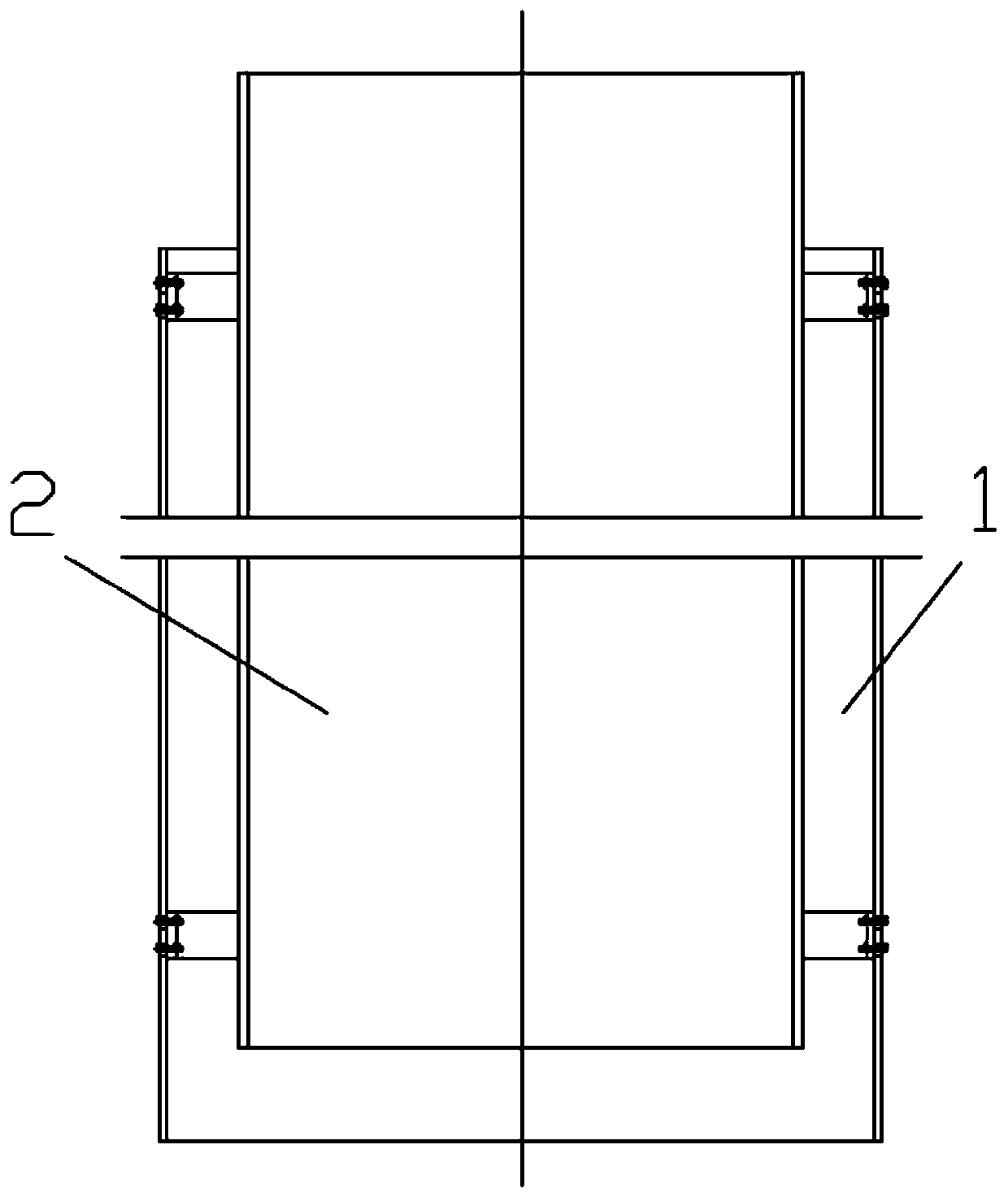

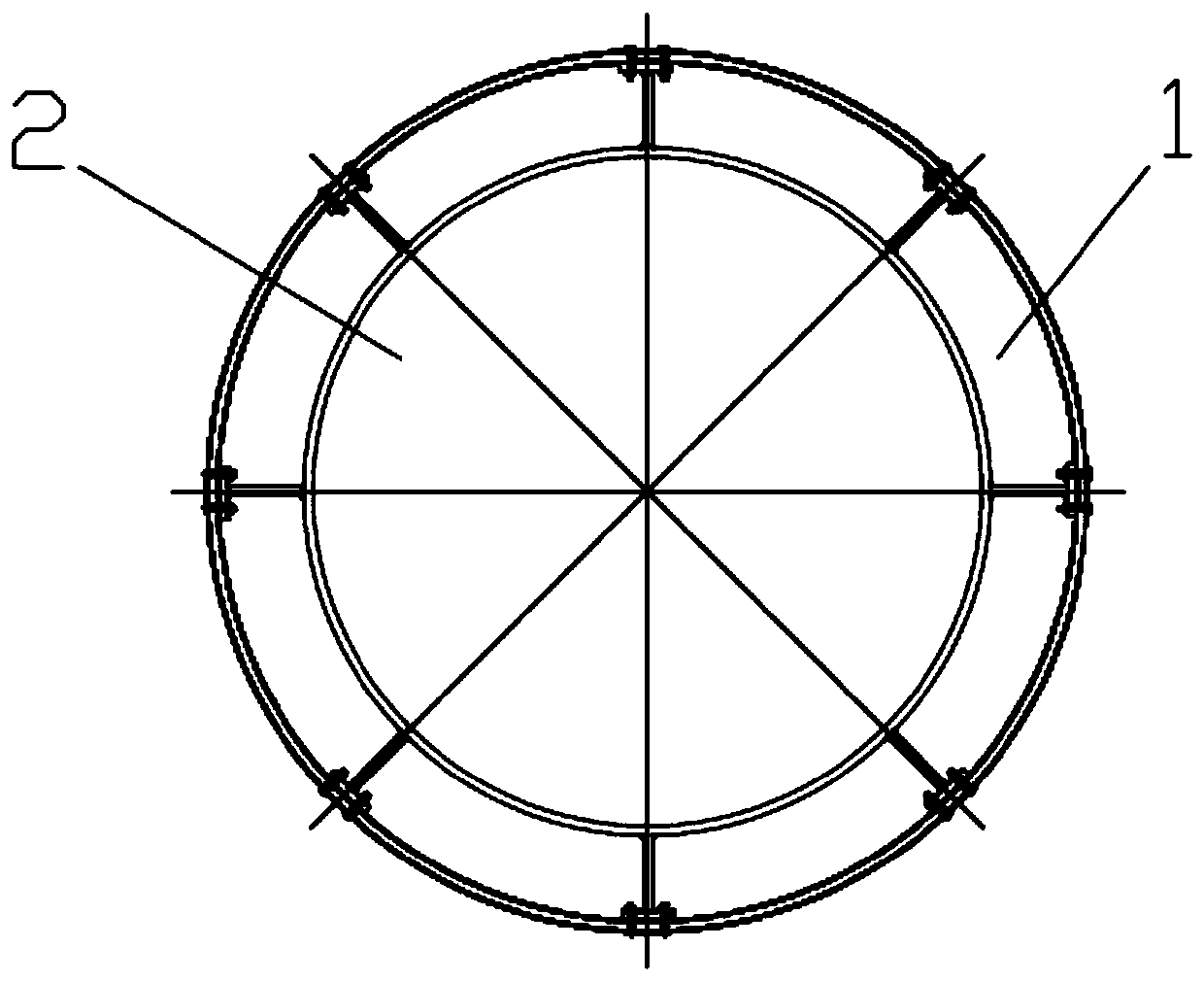

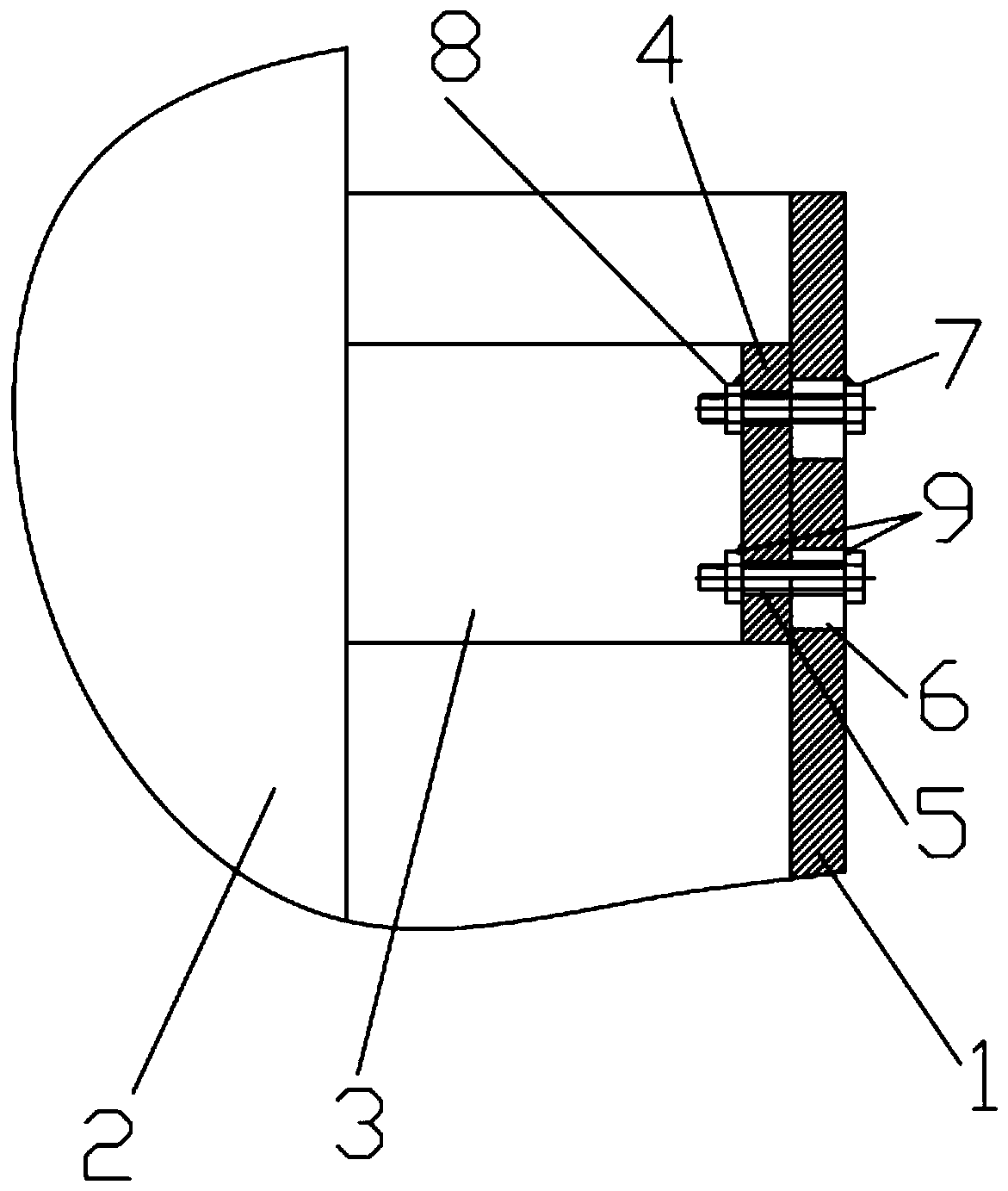

[0020] Specific Embodiment 1: The connection structure between the ascending cylinder and the descending cylinder of the gasification furnace in this embodiment, the gasification furnace includes the ascending cylinder 1, the descending cylinder 2, and the upper and lower ends of the ascending cylinder 1 are provided with 6 to 12 Ts Shaped support assembly, the T-shaped support assembly is made up of spacer plate 3 and connecting plate 4, a plurality of circular holes 5 are set on the ascending cylinder 1, a plurality of waist-shaped holes 6 are set on the connecting plate 4, and the circular holes 5 and the number of waist-shaped holes 6 are the same, and the axes of the corresponding round holes 5 and 6 are coincident. The ascending cylinder 1 is bolted to the connecting plate 4 through hexagonal bolts 7 and hexagonal nuts 8 .

[0021] The beneficial effect of this implementation mode:

[0022] 1. The connection structure and manufacturing method of the ascending cylinder an...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: one end of the distance plate 3 is welded to the connecting plate 4 , and the other end of the distance plate 3 is welded to the descending cylinder 2 .

[0025] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that: 6 to 12 groups of hole groups are evenly distributed around the upper and lower ends of the ascending cylinder 1, and each group of hole groups includes 4 round holes 5, and The four round holes 5 are arranged in a square; the connecting plate 4 is provided with four waist-shaped holes 6, and the four waist-shaped holes 6 are arranged in a square.

[0027] Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com