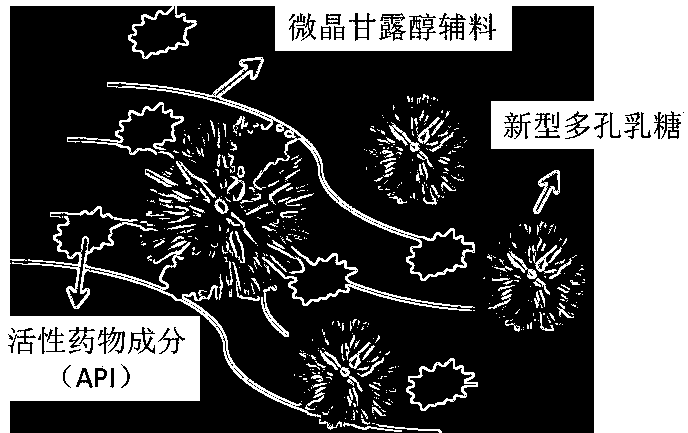

Quick-acting orally disintegrating tablet and powder based on novel porous lactose and microcrystalline mannitol auxiliary materials

A technology of alcohol excipients and mannitol, which is applied in the field of quick-acting orally disintegrating tablets and powders, can solve the problems of unfavorable safety audit and toxicology research, lack of novelty, short development history of orally disintegrating tablets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Based on the quick-acting orally disintegrating tablet and powder of the novel porous lactose and microcrystalline mannitol excipients, this embodiment provides a preparation step of acetaminophen quick-acting orally disintegrating tablet and powder, including:

[0034] S1: Dissolve acetaminophen in ethanol solvent to obtain 22.5g / L acetaminophen ethanol solution;

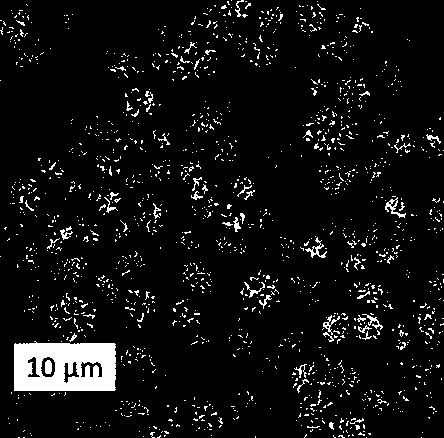

[0035] S2: The amorphous lactose obtained by spray drying is added to the acetaminophen ethanol solution prepared by S1 at a concentration of 10g / L, and the novel porous lactose is obtained by crystallization, and the adsorption of the active pharmaceutical ingredients is completed;

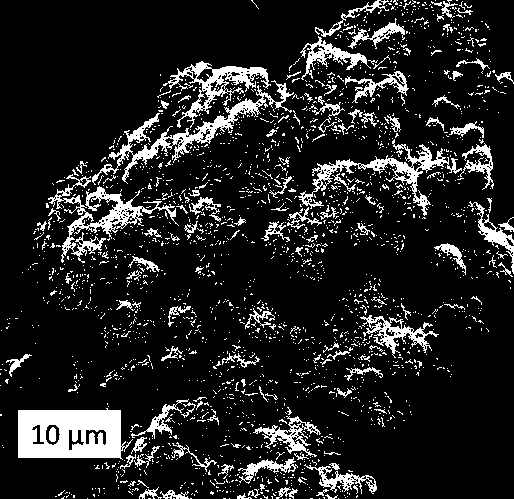

[0036] S3: With the ratio of mannitol to ethanol of 1g:200mL (ie 5g / L), add 0.5g / mL mannitol aqueous solution to the ethanol mixed solution prepared by S2, which is a cotton-absorbent solid-ethanol mixed matrix;

[0037] S4: After the obtained mixture is dried, 0.5 g of the obtained solid is compressed into tablets or ground into powder...

Embodiment 2

[0040] Based on the quick-acting orally disintegrating tablets and powders of the novel porous lactose and microcrystalline mannitol excipients, this embodiment provides a preparation step of aspirin (also called acetylsalicylic acid) quick-acting orally disintegrating tablets and powders, including:

[0041] S1: Add the heated and dissolved 1g / mL lactose aqueous solution to the ethanol solution at a ratio of 1:50 (volume ratio) to prepare the new porous lactose, which is separated for use; with the ratio of mannitol to ethanol of 1g:100-500mL, Add 0.5 g / mL mannitol aqueous solution to the ethanol solution to prepare the microcrystalline mannitol, which is separated for use;

[0042] S2: Dissolve acetylsalicylic acid in an ethanol solvent to obtain 80g / L of an ethanol solution containing acetylsalicylic acid, and mix with 43g of new porous lactose prepared by S1 per liter to complete drug adsorption;

[0043] S3: Mix the microcrystalline mannitol made from S1 with ethanol at a ratio ...

Embodiment 3

[0047] Based on the quick-acting orally disintegrating tablet and powder of the novel porous lactose and microcrystalline mannitol excipient, this embodiment provides a preparation step of a caffeine quick-acting orally disintegrating tablet and powder, which includes:

[0048] S1: Dissolve or disperse 5g / L caffeine in an ethanol solvent to obtain an ethanol solution containing active pharmaceutical ingredients;

[0049] S2: With a ratio of mannitol to ethanol of 1g:250mL (ie 4g / L), add 0.5g / mL mannitol aqueous solution to the above ethanol mixed solution to form a cotton-absorbent solid-ethanol mixed matrix;

[0050] S3: After the obtained mixture is dried, the obtained solid is compressed into tablets or ground into powder.

[0051] The caffeine fast-acting orally disintegrating tablets and powders obtained by the above method contain ~56% by mass of the active pharmaceutical ingredient (ie API), 0% by mass of the new porous lactose, and ~44% by mass of microcrystalline mannose It s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Aperture diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com