Reusable welded hydraulic cover of boiler and pressure vessel and manufacturing method of reusable welded hydraulic cover

A technology for pressure vessels and manufacturing methods, which is applied in the direction of pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of poor stress conditions, poor economic benefits, and high pressure parameters of flat-plate welded structures, so as to improve the utilization rate and Economic benefit, low utilization rate, and the effect of manufacturing process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

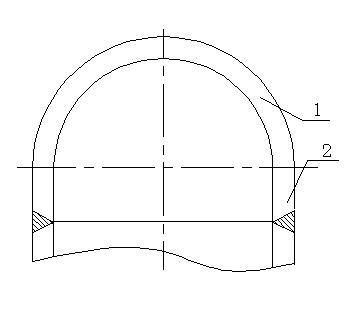

[0028] A welded water pressure cover for boilers and pressure vessels that can be used multiple times. Its composition includes: a cover 1, the lower end of the cover has more than one hydraulic pressure margin 2, and the cover is connected to a transition pipe , the cover is connected to the flange 3, and a central hole 4 is opened on the cover.

Embodiment 2

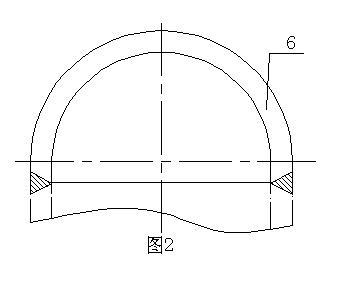

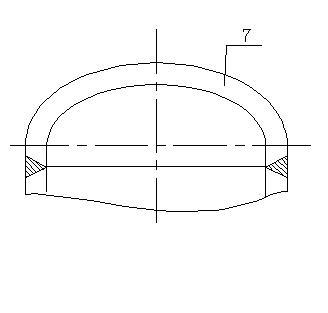

[0030] The welded water pressure cover of the boiler and pressure vessel that can be used multiple times, the cover can be a spherical cover 6, an oval cover 7, a flat bottom cover 8, a tube sheet cover 9, a flat cover 10 or flange cover 11.

Embodiment 3

[0032] The invention discloses a manufacturing process method for welded hydraulic sealing covers of boilers and pressure vessels which can be used repeatedly. The hydraulic sealing covers are manufactured after type selection and strength calculation. The hydraulic sealing cover has a central hole to connect with the flange or pipe joint; the welding groove of the sealing cover is reserved in the design and the total process allowance for processing after multiple hydraulic pressures is L=h×n; before the hydraulic pressure test, The hydraulic cover is connected to the large connecting pipe of the product by welding. After each hydraulic test, the sealing cover or the transitional connecting pipe shall be cut within the hydraulic pressure allowance of the large connecting pipe, and the base material shall not be damaged. Process the welding groove of the cover. In special cases, the cover can also be cut according to the requirements, and the h value should be adjusted accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com