A Method for Promoting the Regeneration of Carbon Dioxide Absorbent Using Throttling Expansion Principle

A technology of throttling expansion and carbon dioxide, which is applied in chemical instruments and methods, separation methods, reagents, etc., can solve the problems of low gas-liquid mass transfer efficiency, oxidative degradation, and increased energy consumption, and achieve shortened residence time and high mass transfer efficiency. The effect of improving and reducing the material consumption of absorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

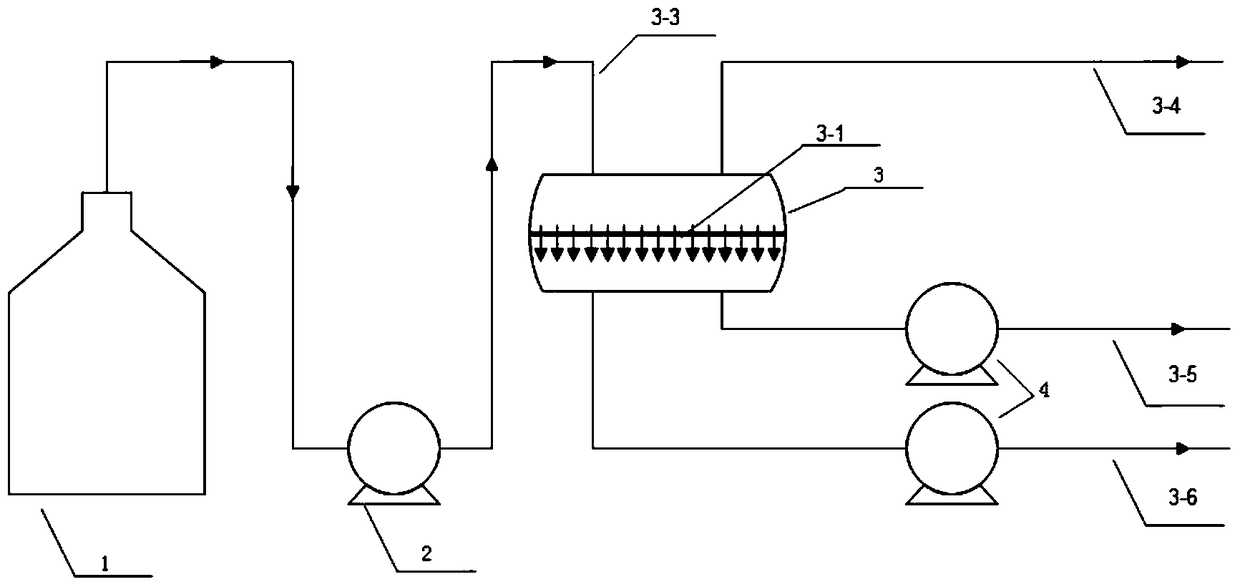

[0048] The mass composition is 20%MDEA+40%NHD+40%H 2 Absorbent for O (initially loaded CO 2 The concentration is 1.30mol / L), using a metal sintered plate with a nominal pore size of 2μm and a hydraulic diameter of 4.8cm as the throttling element, the experimental device is as follows figure 1 shown. Operating conditions: The pressure difference is 70kPa (100kPa absolute pressure on the upstream side of the throttling element, 30kPa absolute pressure on the downstream side), the regeneration temperature is 70°C, and the absorbent flow rate is 0.9L / h.

[0049] When the system reaches a steady state, detect the CO in the absorbent regeneration lean liquid flowing out from the absorbent regeneration lean liquid outlet 3-5 2 Concentration 0.06mol / L, CO 2 The desorption rate is 95.1%, and the average residence time of the absorbent in the throttling device is 7.2s.

Embodiment 2

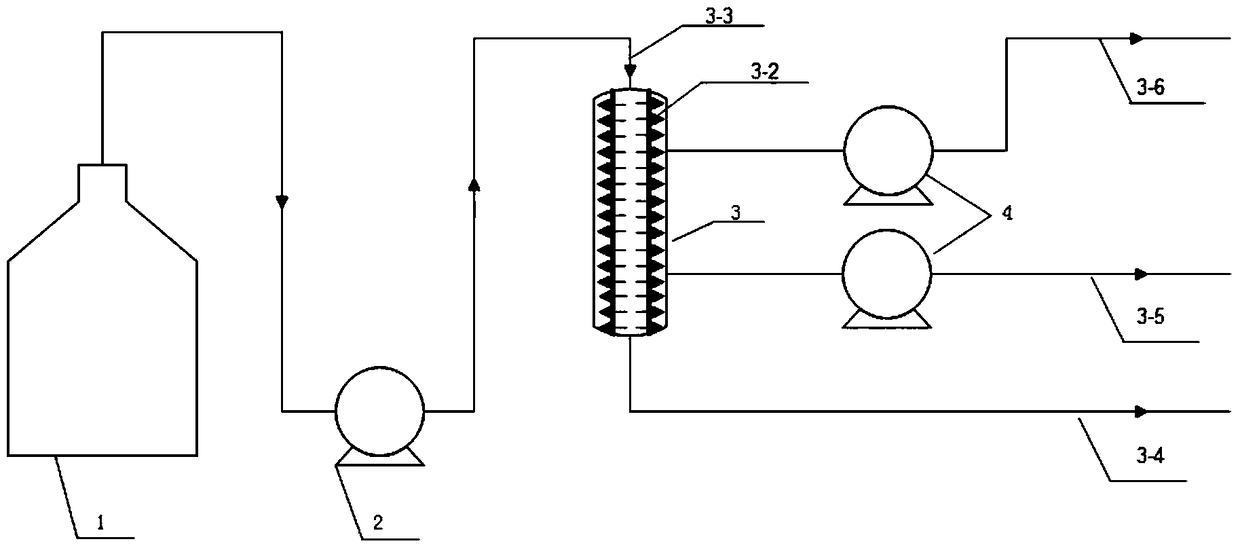

[0051] The mass composition is 10%MDEA+50%NHD+40%H 2 Absorbent for O (initially loaded CO 2 Concentration is 0.786mol / L), using the PTFE hollow fiber membrane module with packing number n of 10, pore diameter of 0.65 μm, and porosity of 65% as the throttling element, the experimental device is as follows figure 2 shown. Operating conditions: differential pressure 70kPa (absolute pressure 100kPa on the upstream side of the throttling element (inside the hollow fiber tube), 30kPa absolute pressure on the downstream side (outside the hollow fiber tube)), regeneration temperature 60°C, absorbent flow rate 1.2L / h .

[0052] When the system reaches a steady state, detect the CO in the absorbent regeneration lean liquid flowing out from the absorbent regeneration lean liquid outlet 3-5 2 The concentration is 0.14mol / L, the desorption rate is 82.8%, and the average residence time of the absorbent in the throttling device is 6.3s.

Embodiment 3

[0054] The mass composition is 30%MDEA+30%NHD+40%H 2 Absorbent for O (initially loaded CO 2 Concentration is 2.01mol / L), using a metal sintered plate with a nominal pore diameter of 2μm and a hydraulic diameter of 4.8cm as the throttling element, the experimental device is as follows figure 1 shown. Operating conditions: pressure difference is 100kPa (absolute pressure on the upstream side of the throttling element is 200kPa, and absolute pressure on the downstream side is 100kPa), the regeneration temperature is 70°C, and the flow rate of the absorbent is 72L / h.

[0055] When the system reaches a steady state, detect the CO in the absorbent regeneration lean liquid flowing out from the absorbent regeneration lean liquid outlet 3-5 2 The concentration is 0.62mol / L, the desorption rate is 69.4%, and the average residence time of the absorbent in the throttling device is 0.1s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com