Packaging container with Anti-counterfeit effect

a packaging container and anti-counterfeit technology, applied in the field of product packaging, can solve the problems of illegal means to usurp profits, increase costs, use weakness of packaging sealing products, etc., and achieve the effect of increasing the anti-counterfeit effect, increasing the consumption of materials, and not increasing the packaging material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

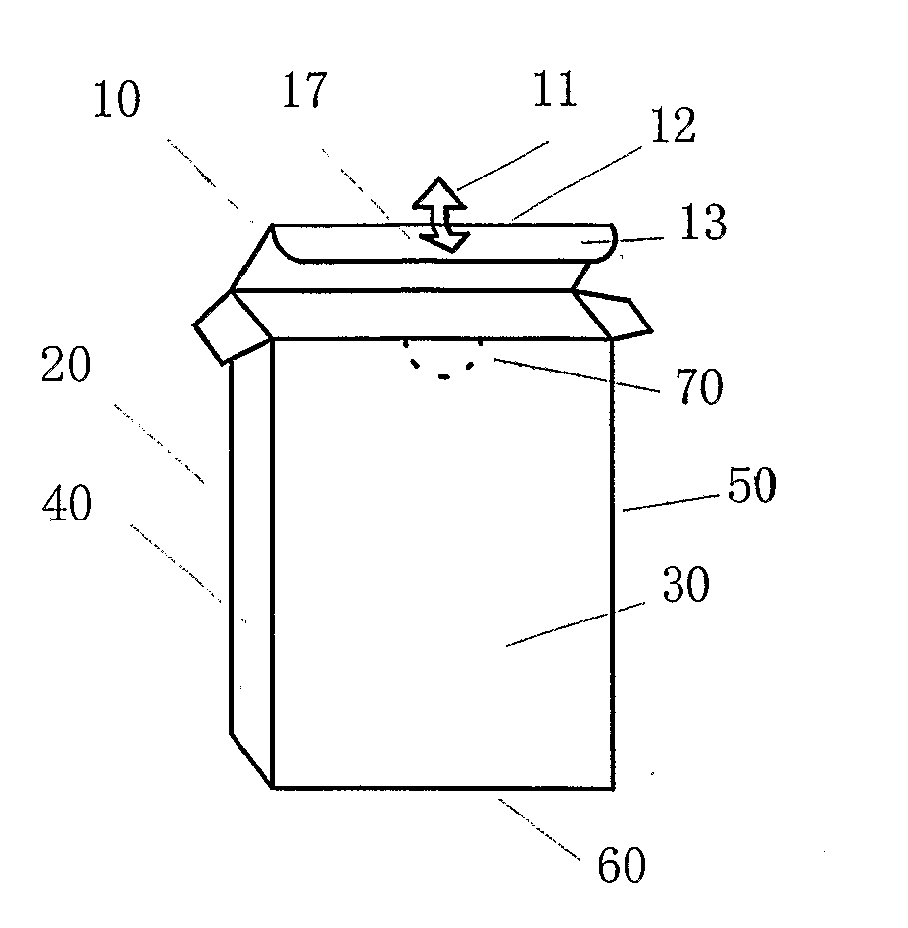

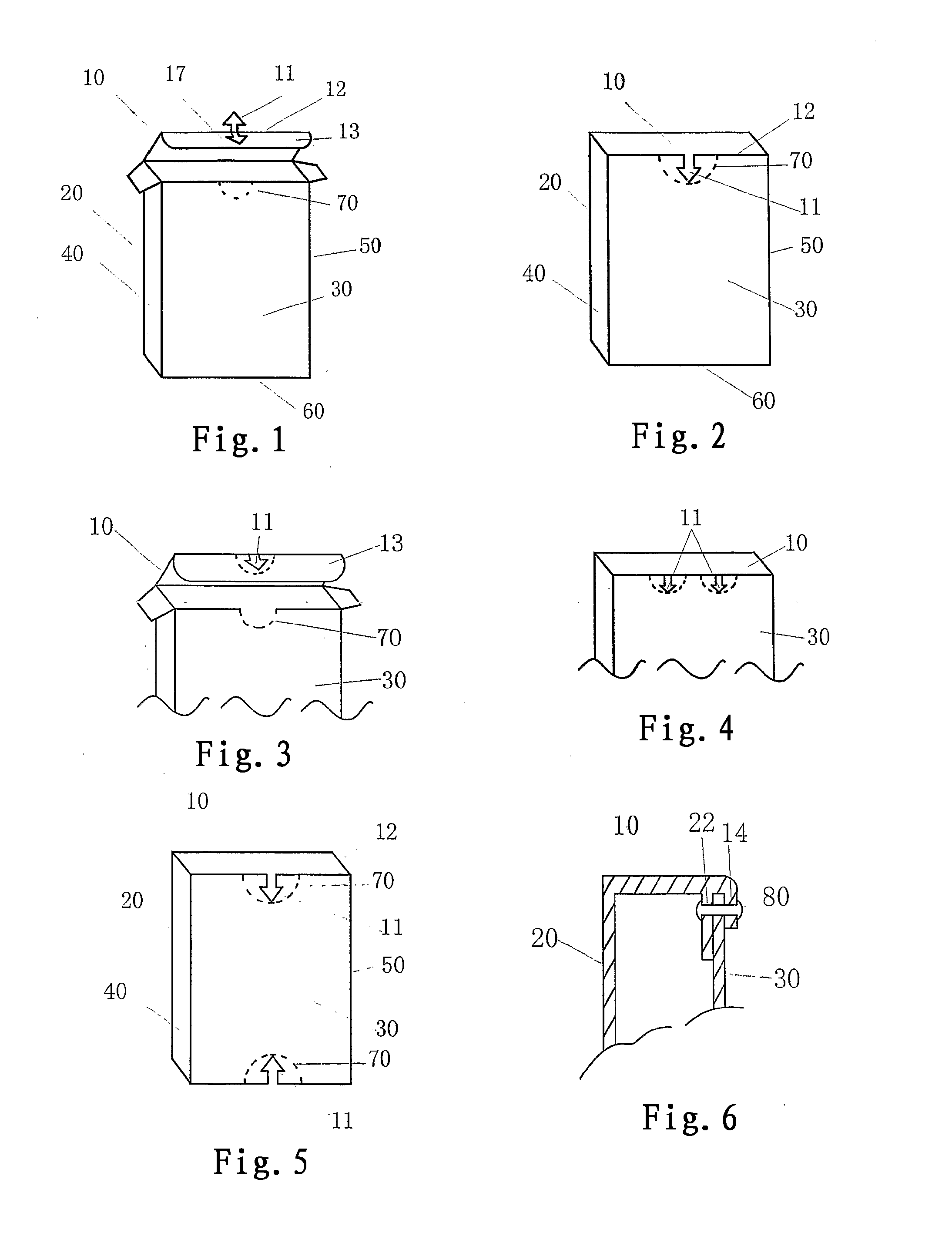

[0056]A referring to FIGS. 1, 2 and 3, the present invention provides a function-expanded application of an insertion tongue of a packaging container. The packaging container is a hexagonal packaging box comprising a cover panel (10), a first panel (20), a second panel (30), a first side panel (40), a second side panel (50) and a bottom panel (60). An insertion tongue (13), which is formed by bending the cover panel (10) along the folding line (12), is inserted into the inner chamber of the packaging box. It is characterized in that at least one sealing strip (11) is separated from the insertion tongue (13) and is connected to the cover panel (10) at the folding line (12); the sealing strip (11) is not inserted into the inner chamber of the packaging box along with the insertion tongue (13), but is pressed and bonded on the corresponding outer surface of the second panel (30) and is securely connected with the second panel; and a tearing line (70) is provided on the second panel (3...

sixth embodiment

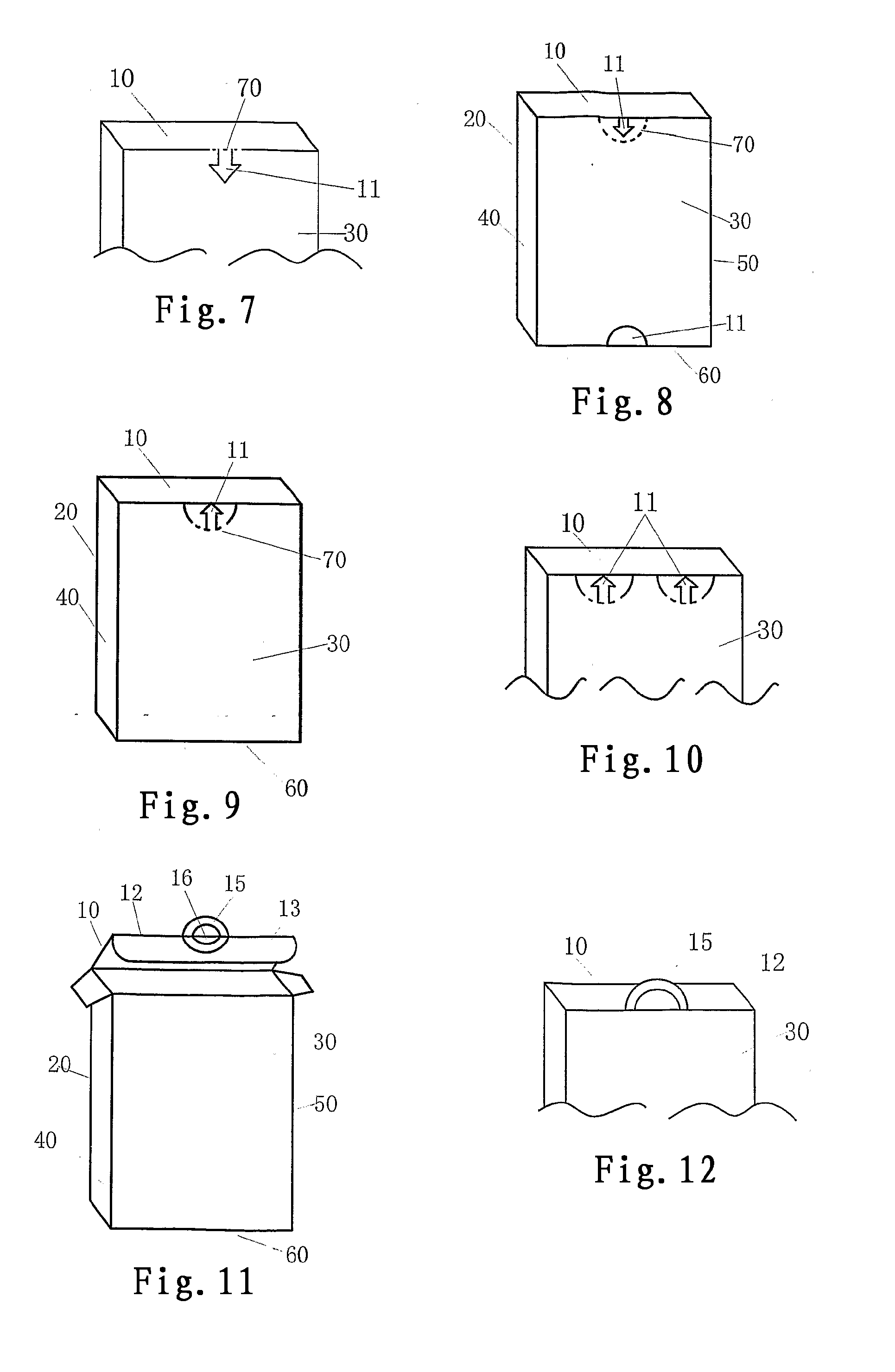

[0062]A referring to FIG. 7, the present invention provides a function-expanded application of an insertion tongue of a packaging container. The packaging container is a hexagonal packaging box comprising a cover panel (10), a first panel (20), a second panel (30), a first side panel (40), a second side panel (50) and a bottom panel (60). An insertion tongue (13), which is formed by bending the cover panel (10) along a folding line (12), is inserted into the inner chamber of the packaging box. It is characterized in that one sealing strip (11) is separated from the insertion tongue (13) and is connected to the cover panel (10) at the folding line (12); the sealing strip (11) is not inserted into the inner chamber of the packaging box along with the insertion tongue (13), but is pressed and bonded on the corresponding outer surface of the second panel (30) and is securely connected with the second panel; and a tearing line (70) is provided on the sealing strip (11) near the folding ...

seventh embodiment

[0063]A referring to FIG. 8, the bottom panel (60) is provided with an insertion tongue (13) and one sealing strip (11) is separated from the insertion tongue (13). The sealing strip (11) is not inserted into the inner chamber of the packaging box along with the insertion tongue (13), but is pressed and bonded on the corresponding outer surface of the second panel (30) adjacent to the bottom panel (60) and is securely connected with the second panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com