Dental complex color machinable zirconia ceramics and preparation method

A zirconia ceramic, zirconia technology, applied in dental preparations, dentistry, dental prostheses, etc., can solve the problems of unfavorable abutment retention and protection, increased light scattering, restoration failure, etc. The effect of repairing success rate, improving machining efficiency and accuracy, and reducing the effect of translucency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

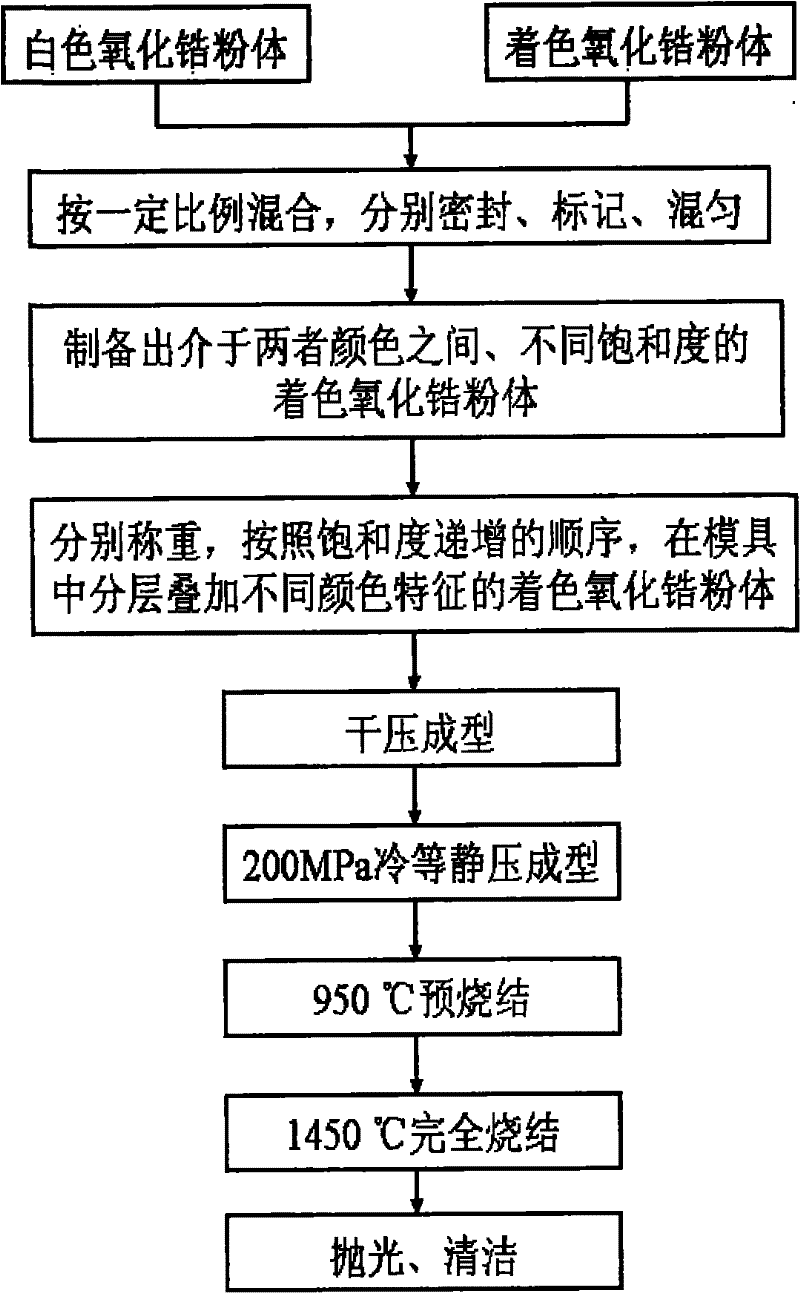

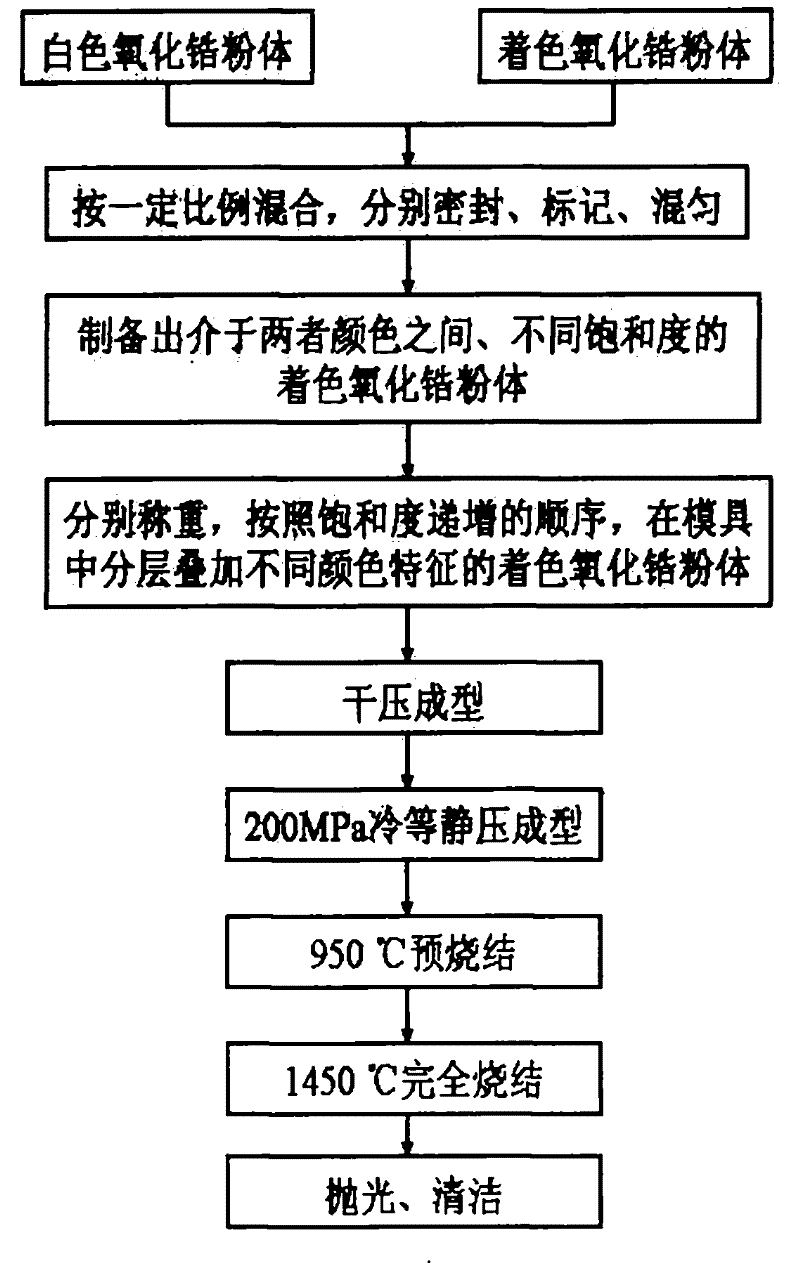

[0022] Preparation of machinable zirconia ceramics with a main color of light yellow and five saturations, and dental CAD / CAM system for the production of full crown restorations of maxillary central incisors:

[0023] Raw materials of zirconia powder: white and yellow magenta zirconia powder, the main components are (wt%): Y 2 o 3 5.2±0.5, Al 2 o 3 0.1~0.4, and trace Na 2 O, SiO 2 , Fe 2 o 3 , the rest is ZrO 2 , the actual particle size is about 90nm.

[0024] Preparation of colored zirconia powder: white zirconia powder and yellow magenta zirconia powder are respectively: 60%: 40%, 70%: 30%, 80%: 20%, 90%: 10%, 95%: 5% were weighed and mixed, and the total mass of each mixed powder was 10 g; put it into a sealed tube, mark it as No. 1, 2, 3, 4, and 5 according to the above ratio, and mix well.

[0025] Preparation of multi-color machinable zirconia ceramic green body: according to the order of 1 to 5, weigh the colored zirconia mixed powder with an electronic balan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com