Magnetic-bias currency detecting magnetic head with sensitive direction parallel to detection face

A technology of magnetic bias and detection surface, which is applied in the authenticity inspection of banknotes, magnetic resonance measurement, and measurement devices, etc., and can solve the problems of low sensitivity and signal-to-noise ratio of indium antimonide Hall elements, sensitivity and signal-to-noise ratio of banknote verification heads Low ratio, large noise of indium antimonide sensor, etc., to achieve the effect of not being prone to environmental temperature and stress, low cost, high sensitivity and signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

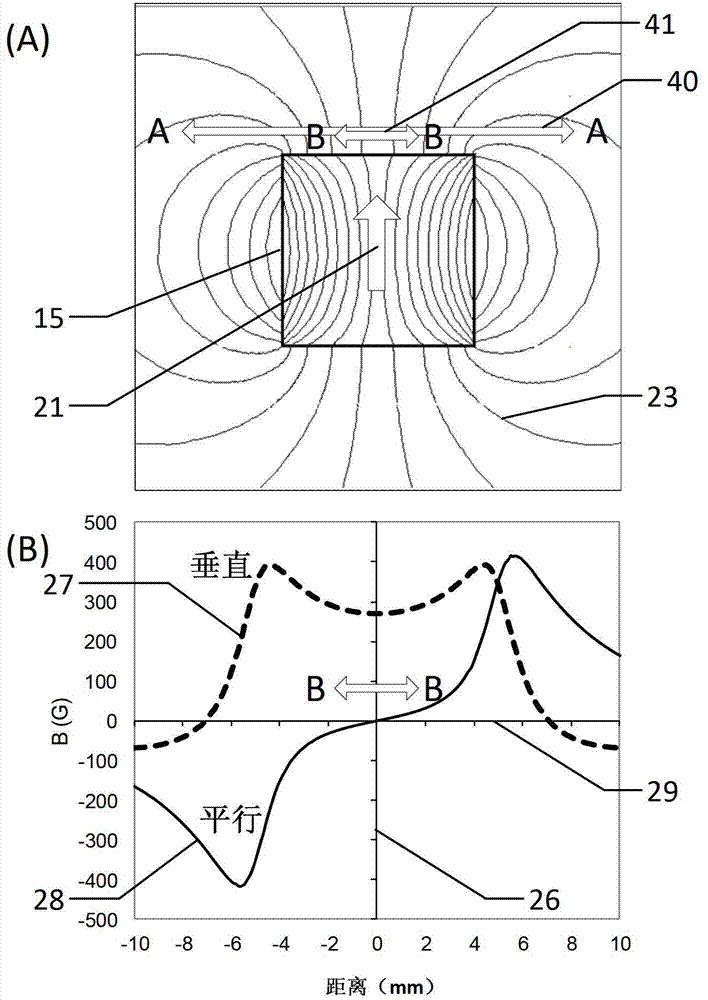

[0068] Figure 6 (A) is a magnetic field line distribution diagram of a magnetic field generated by a rectangular permanent magnet having a concave structure in the magnetic head according to Example 1 of the present invention. Such as Figure 6 As shown in (A), the permanent magnet 55 has a groove 52 on the surface close to the detection surface 40 , and the depth direction of the groove is perpendicular to the surface of the permanent magnet 55 formed with the groove. The magnetization direction 51 of the permanent magnet 55 is perpendicular to the detection surface 40 . At the center of the detection surface 40, the magnetic field 53 generated by the permanent magnet 55 with the groove 52 is perpendicular to the detection surface 40, thus eliminating the horizontal magnetic field component at the sensor chip 41 such as the TMR element.

[0069] Figure 6 (B) is a magnetic field intensity distribution diagram along the detection surface 40, wherein the dotted line 57 is t...

example 2

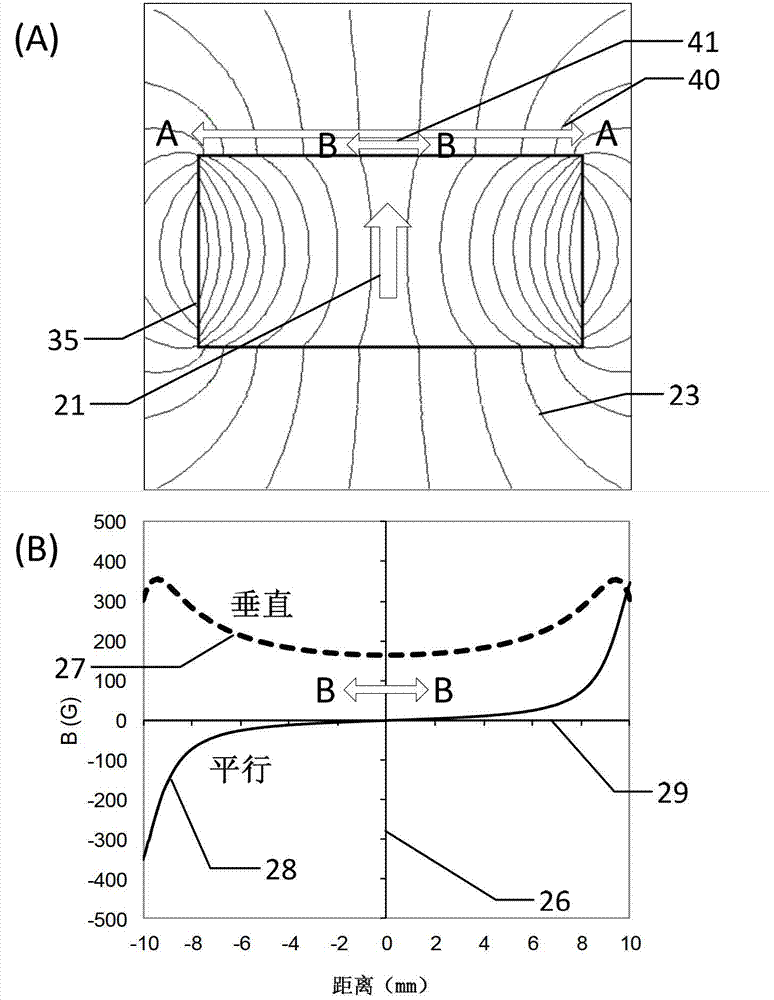

[0072] Figure 7 (A) is a distribution diagram of the magnetic force lines of the magnetic field generated by the magnetic bias element in the magnetic head of Example 2. Such as Figure 7 (A), the permanent magnet with a rectangular cross-section 65 is covered with a soft magnetic alloy sheet, also called “magnetic pole piece” 64 , which is used to adjust the magnetic field distribution parallel to the detection surface 40 . Pole pieces 64 are typically made of a soft magnetic alloy, such as permalloy. The magnetization direction 61 of the permanent magnet 65 is perpendicular to the detection surface 40 , and the magnetization direction of the pole piece 64 is determined by the magnetization direction of the permanent magnet 65 . The groove 62 of the pole piece is used to reduce the magnetic field strength of the magnetic field in the direction parallel to the detection surface 40 .

[0073] Figure 7 (B) is the magnetic field intensity distribution diagram of example 2 alo...

example 3

[0076] Figure 8 (A) is a distribution diagram of the magnetic force lines of the magnetic field generated by the magnetic bias element in the magnetic head of Example 3. Such as Figure 8 As shown in (A), the permanent magnet with a rectangular cross section 75 is covered with a soft magnetic alloy sheet, also called a magnetic pole piece 74 , which is used to adjust the magnetic field distribution of the permanent magnet parallel to the detection surface 40 . Pole pieces 74 are typically made of a soft magnetic alloy, such as permalloy. The magnetization direction 71 of the permanent magnet 75 is perpendicular to the detection surface 40 , and the magnetization direction of the pole piece 74 is determined by the magnetization direction of the permanent magnet 75 . The opening 72 on the pole piece 74 is used to reduce the strength of the magnetic field parallel to the detection surface 40 .

[0077] Figure 8 (B) is a magnetic field intensity distribution diagram along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com