Light conducting board and backlight module

A technology of backlight module and light guide plate, applied in the direction of light guide, optics, optical components, etc., can solve the problem of not being able to fundamentally eliminate the shadow area, etc., and achieve the effect of improving the uniformity of light emission and the utilization rate of light energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The backlight module of the present invention will be further described in detail below with reference to the drawings and multiple embodiments.

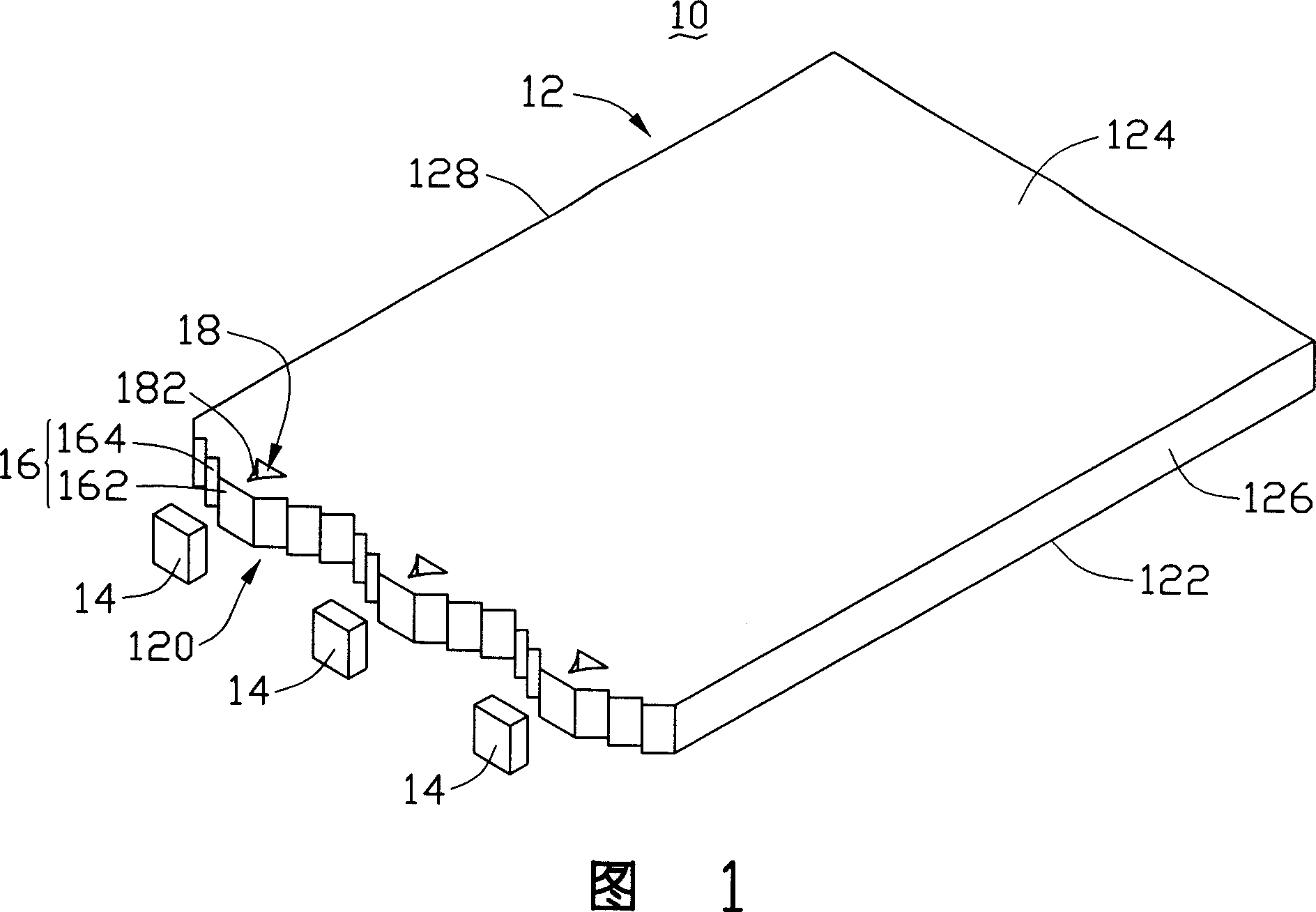

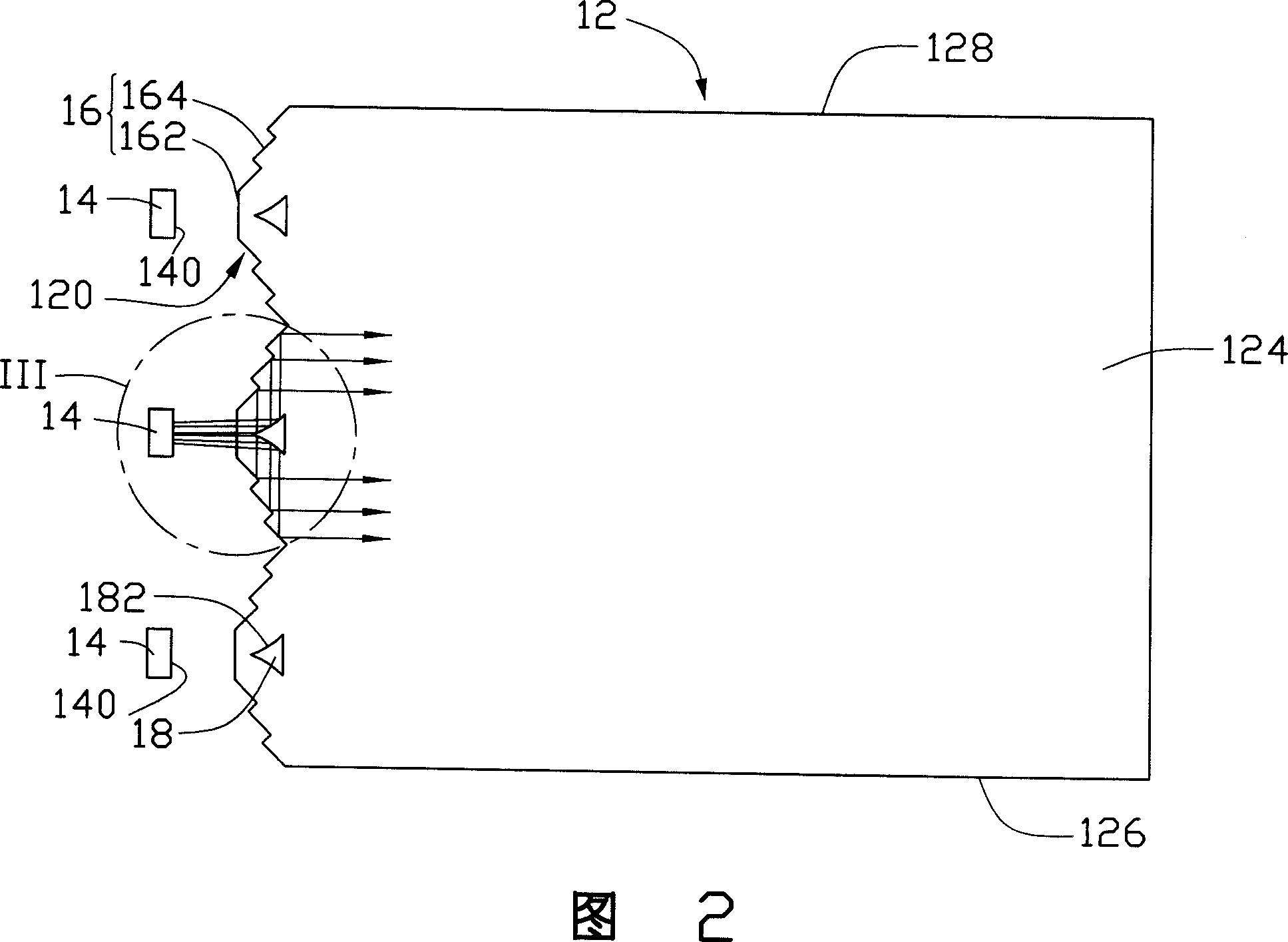

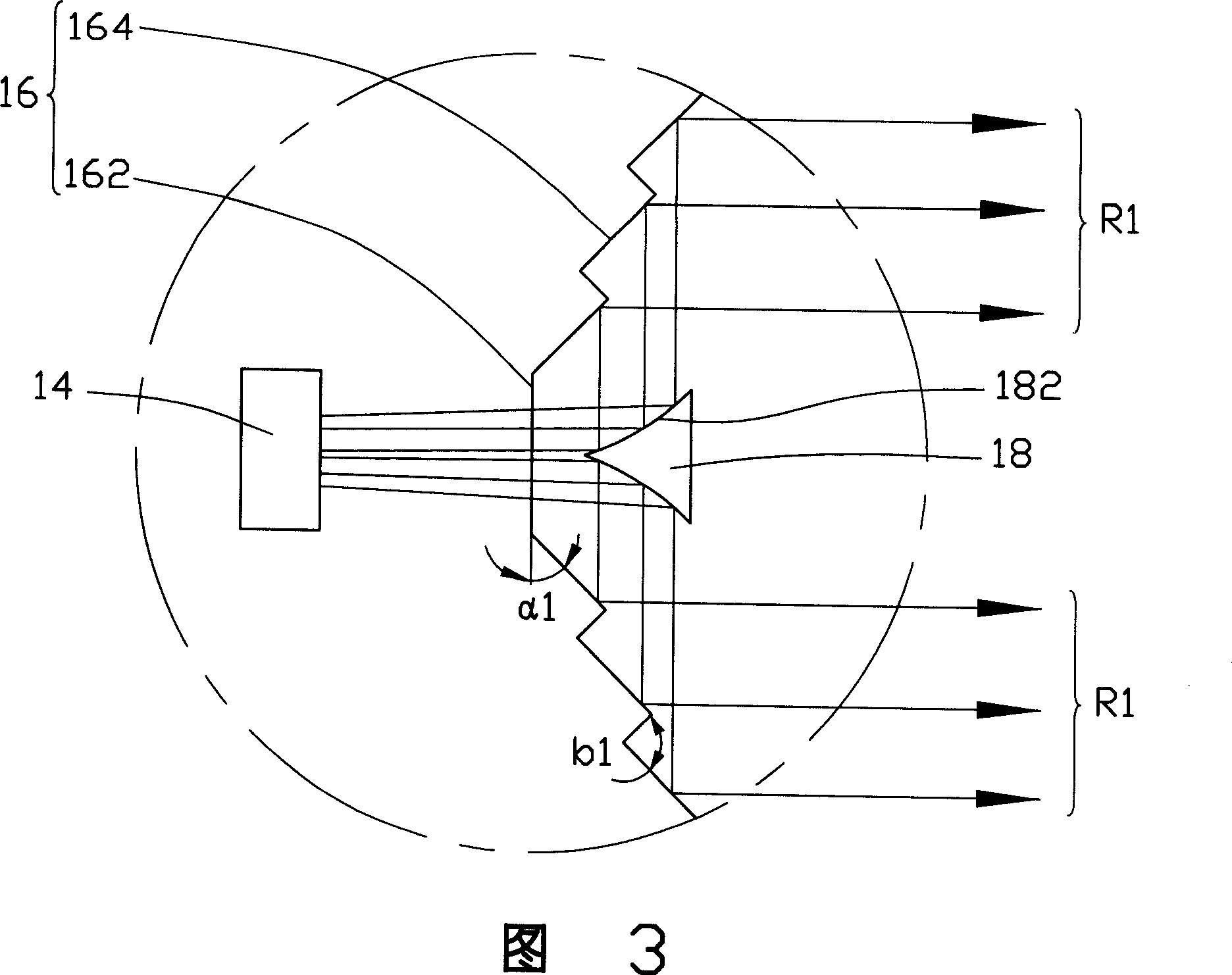

[0035] Please refer to FIG. 1 to FIG. 3 together. The first embodiment of the present invention (please add the description of R1) provides a backlight module 10, which includes: a light guide plate 12, the light guide plate 12 includes a light incident surface 120, A light-emitting surface 122 connected to the light-incident surface 120, a light-reflecting surface 124 corresponding to the light-emitting surface 122, and two side surfaces 126, 128 connected to the light-incident surface 120; Light emitting diode (Light Emitting Diode, LED) light sources 14 disposed on the light surface 120 , each light source 14 includes a light emitting surface 140 parallel to the light incident surface 120 of the light guide plate 12 . The light guide plate 12 protrudes and forms a light diffusion part 16 corresponding to each light source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com