Display panel and manufacturing method thereof

一种显示面板、制作方法的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those who are familiar with the technical field of the present invention to further understand the present invention, the preferred embodiments of the present invention are listed below, together with the accompanying drawings, to describe in detail the composition of the present invention and the desired effects .

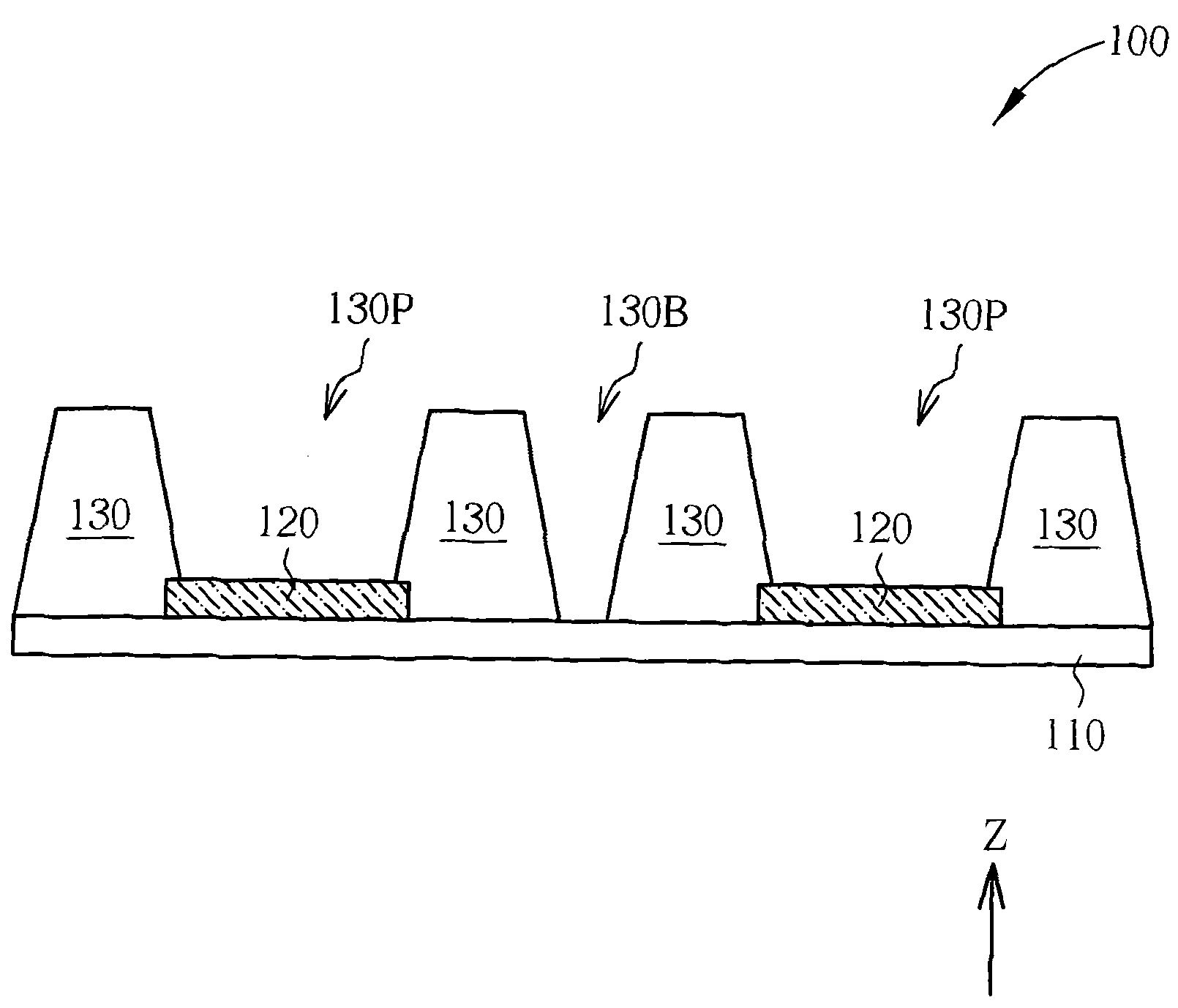

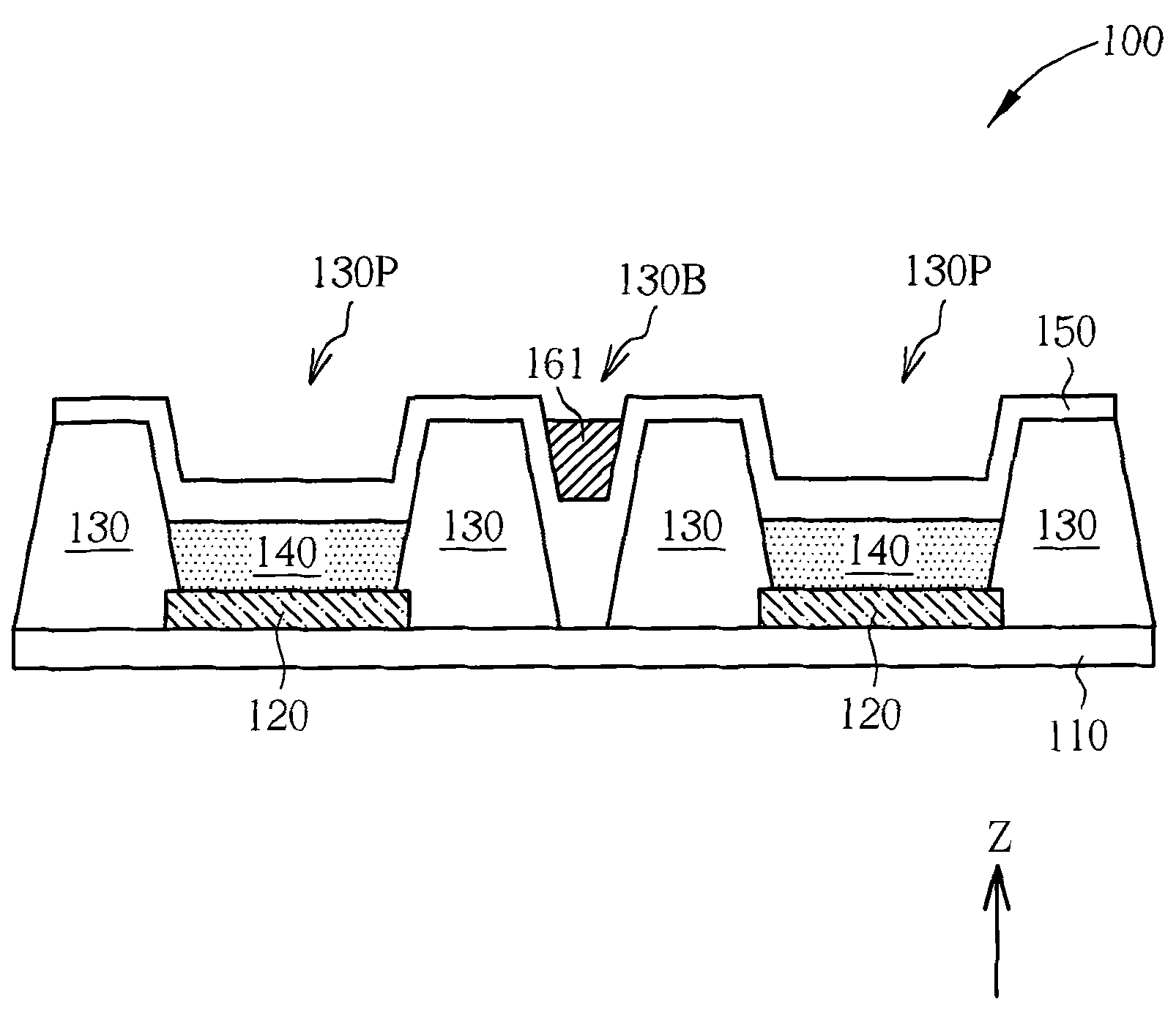

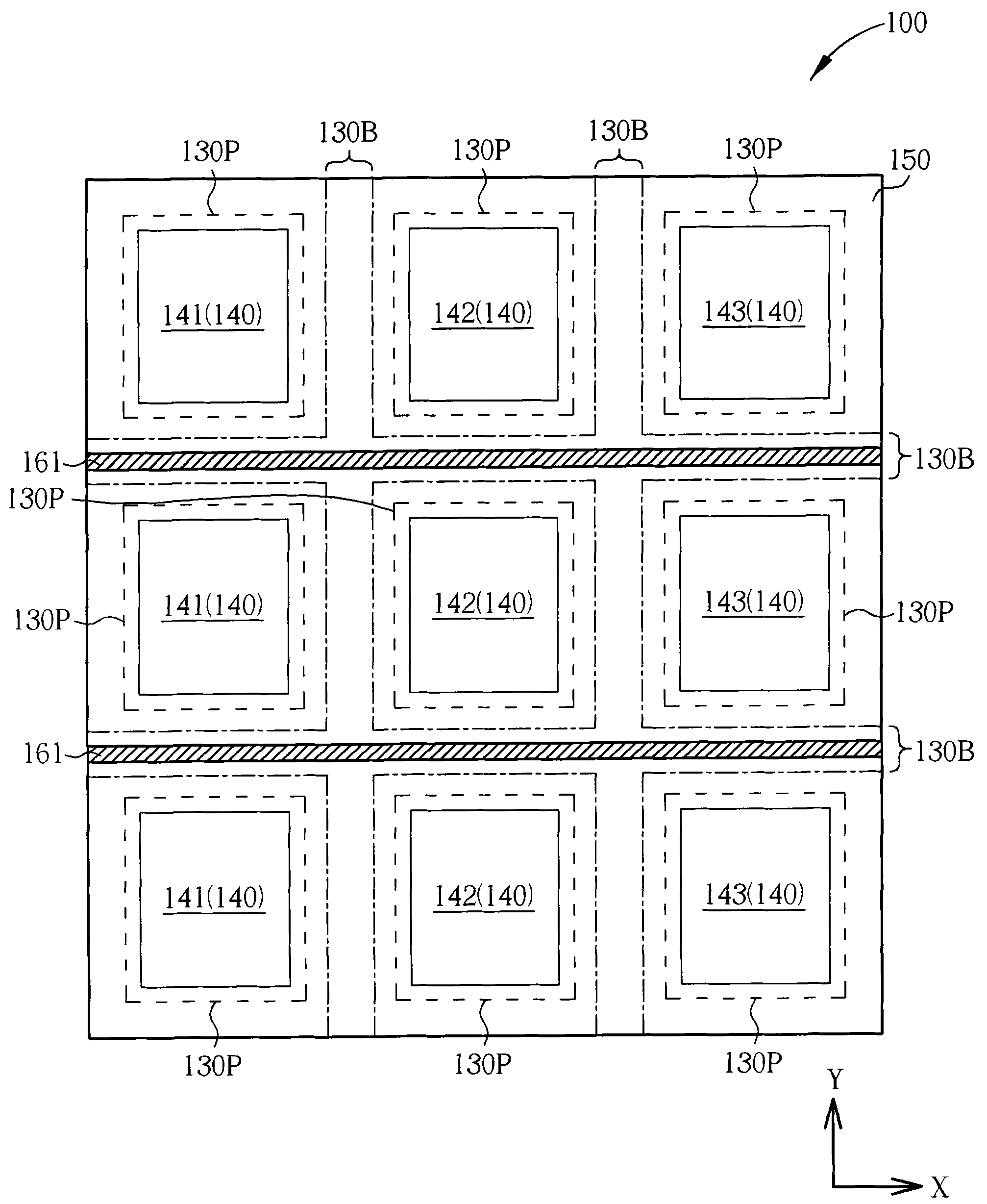

[0030] Please refer to Figure 1A , Figure 1B , Figure 2A , Figure 2B and Figure 2C . Figure 1A , Figure 1B as well as Figure 2A A schematic diagram of a manufacturing method of a first preferred embodiment of the display panel of the present invention is shown. in Figure 1A and Figure 1B is a side view, and Figure 2A for the top view. Figure 2B A schematic top view showing another preferred implementation of the auxiliary electrode of the display panel of the present invention, Figure 2C A schematic top view of another preferred implementation of the auxiliary electrode of the display panel of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com