Full-spectrum LED light source

A LED light source, full-spectrum technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems that are not suitable for human visual preferences, easy to distort colors, color cast, etc., to overcome low excitation efficiency and improve luminous uniformity , The effect of improving color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The phosphor powder can be applied to encapsulation adhesives of various types of LED light sources, such as SMD LEDs, COB LEDs, and the like. Correspondingly, the present invention also provides a method for preparing a full-spectrum LED light source, the method comprising:

[0039] (1) Prepare the LED bracket, set the LED chip on the LED bracket, and connect the LED chip and the LED bracket through metal wires;

[0040] (2) Select and mix yellow powder, blue-green powder, green powder, yellow-green powder, red powder and silica gel according to the formula to obtain fluorescent glue;

[0041] (3) Apply fluorescent glue evenly on the LED chips of the LED bracket, and make the fluorescent glue cover the LED chips and metal wires;

[0042] (4) Baking the packaged LED bracket to obtain a finished product.

[0043]It should be noted that, in the preparation method, the selection principles of the phosphor powder and the LED chip are the same as those described above, and...

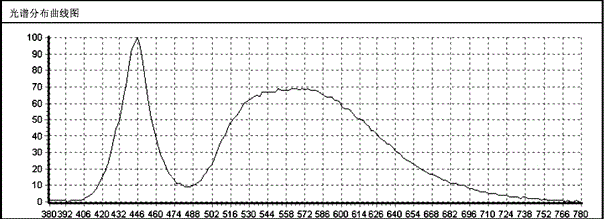

Embodiment 1

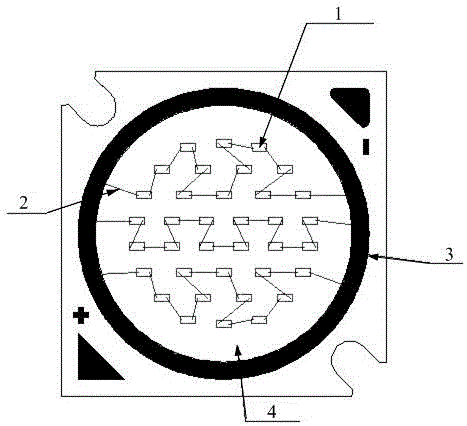

[0046] 19mm×19mm mirror aluminum substrate is used as the bracket, and the blue-ray chip 1 with a dominant wavelength of 455-457.5nmd is selected as the excitation light source. The traditional packaging method is used to fix the blue-ray chip 1 on the bracket with crystal-bonding glue and use the gold wire 2 key Then conduct the dam 3 on the light-emitting surface of the die-bonding area and heat and solidify. Use yellow powder, blue-green powder, green powder, yellow-green powder and red powder to prepare and mix with silica gel to make fluorescent glue 4, then dispensing and heat curing (see the specific packaging structure figure 2 ). Among them, the fluorescent powder is mixed from Intermex YAG05 yellow powder, Hongda 490 blue-green powder, Intermex G2762 green powder, Keheng YG535 yellow-green powder and Youyan 07655 red powder. The yellow powder, blue-green powder, green The weight ratio among powder, yellow-green powder and red powder is 1:0.5:0.36:1.14:0.4.

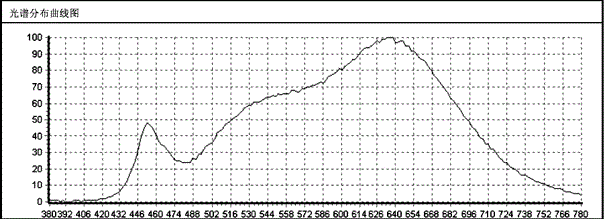

Embodiment 2

[0048] 19mm×19mm mirror aluminum substrate is used as the bracket, and the blue-ray chip 1 with a dominant wavelength of 455-457.5nmd is selected as the excitation light source. The traditional packaging method is used to fix the blue-ray chip 1 on the bracket with crystal-bonding glue and use the gold wire 2 key Then conduct the dam 3 on the light-emitting surface of the die-bonding area and heat and solidify. Use yellow powder, blue-green powder, green powder, yellow-green powder and red powder to prepare and mix with silica gel to make fluorescent glue 4, then dispensing and heat curing (see the specific packaging structure figure 2 ). Among them, the fluorescent powder is mixed from Intermex YAG05 yellow powder, Hongda 490 blue-green powder, Intermex G2762 green powder, Keheng YG535 yellow-green powder and Youyan 07655 red powder. The yellow powder, blue-green powder, green The weight ratio among powder, yellow-green powder and red powder is 1:0.18:0.27:0.18:0.32.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com