Organic electroluminescence device for reducing patterning graphene electrodes based on laser and manufacturing method therefor

An electroluminescent device, a technology of graphene oxide, applied in the field of optoelectronics, can solve the problems of limiting the application of OLEDs, low brightness, and increasing the cost of OLED devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

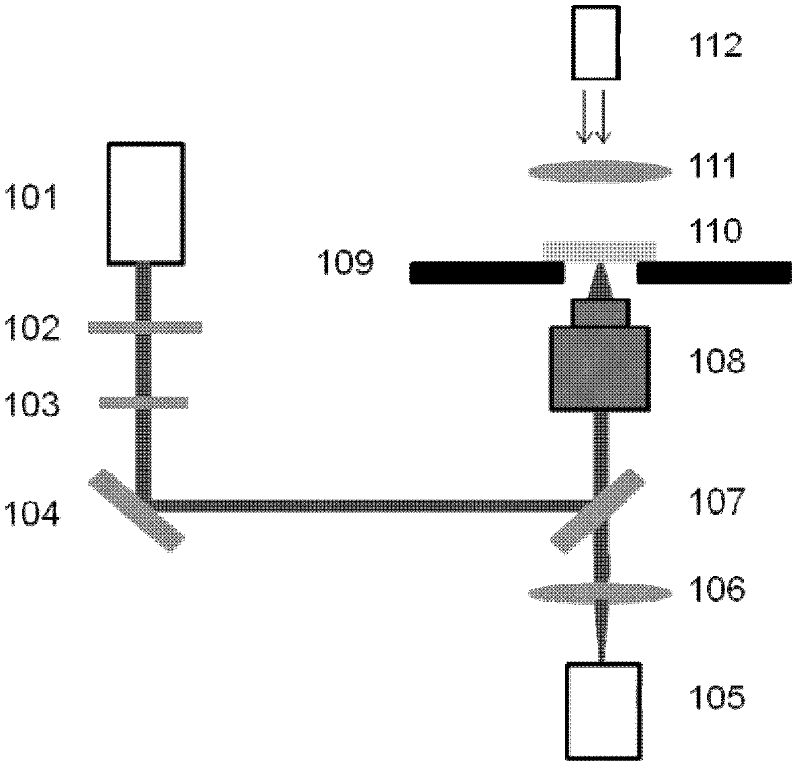

Method used

Image

Examples

Embodiment 1

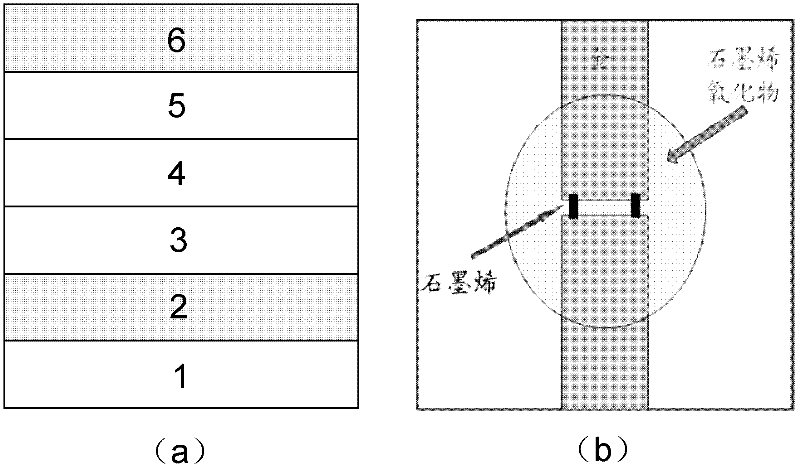

[0047] Fabrication of organic electroluminescent devices with ladder-shaped patterned graphene electrodes. The device structure is: Graphene (graphene, ~20nm) / m-MTDATA(30nm) / NPB(20nm) / Alq 3 (50nm) / LiF(1nm) / Al(100nm), such as figure 2 (a). Proceed as follows:

[0048] (1) On the cleaned substrate, a metal deposition system is used to grow a gold electrode as an extraction electrode, and the vacuum degree of the system is controlled at 1×10 during the growth process. -3 Pa, leave a channel with a width of about 90 μm in the middle of the gold electrode through the copper wire mask, the thickness of the gold electrode is 18 nm, the electrode length is 17 mm, and the width is 5 mm.

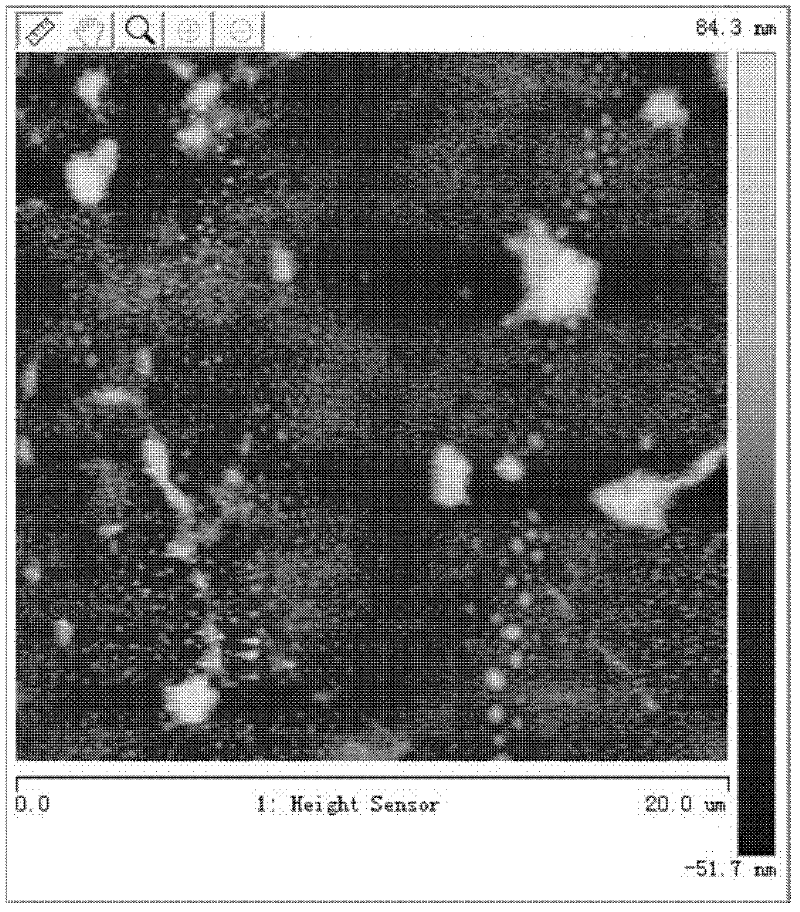

[0049] (2) Graphene oxide is spin-coated on the gold electrode, and the gold electrode and the channel in the middle are completely covered. The spin-coating speed is 1000rpm, and the spin-coating time is 18s. In a vacuum oven at 40°C, the film is Carry out drying treatment, the time is 60min.

...

Embodiment 2

[0058] Fabrication of organic electroluminescent devices with bow-tie patterned graphene electrodes. The device structure is: Graphene (graphene, ~20nm) / m-MTDATA(30nm) / NPB(20nm) / Alq 3 (50nm) / LiF(1nm) / Al(100nm), such as figure 2 (a).

[0059] On the cleaned substrate, a metal deposition system was used to grow a gold electrode as an extraction electrode, and the vacuum degree of the system was controlled at 1×10 during the growth process. -3Pa, a channel with a width of about 50 μm is left in the middle of the gold electrode through a copper wire mask, and the thickness of the gold electrode is 15 nm; then the graphene oxide is spin-coated on the gold electrode, and the gold electrode and its middle The channel is completely covered, the spin-coating speed is 1200rpm, the spin-coating time is 20s, and the film is dried in a vacuum oven at 40°C for 50min; then the graphene oxide is reduced by laser, and the process is the same as As described in Example 1, the selected laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com