Manufacturing device and method of diamond resin abrasive wheel

A technique for resin grinding wheels and preparation devices, which is applied in the direction of grinding devices, metal processing equipment, manufacturing tools, etc., which can solve the problems of easy damage of grinding wheels, complicated batching process, and difficulty in controlling the heating rate of curing process, and achieve high surface quality and preparation Simplified process and convenient platform construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

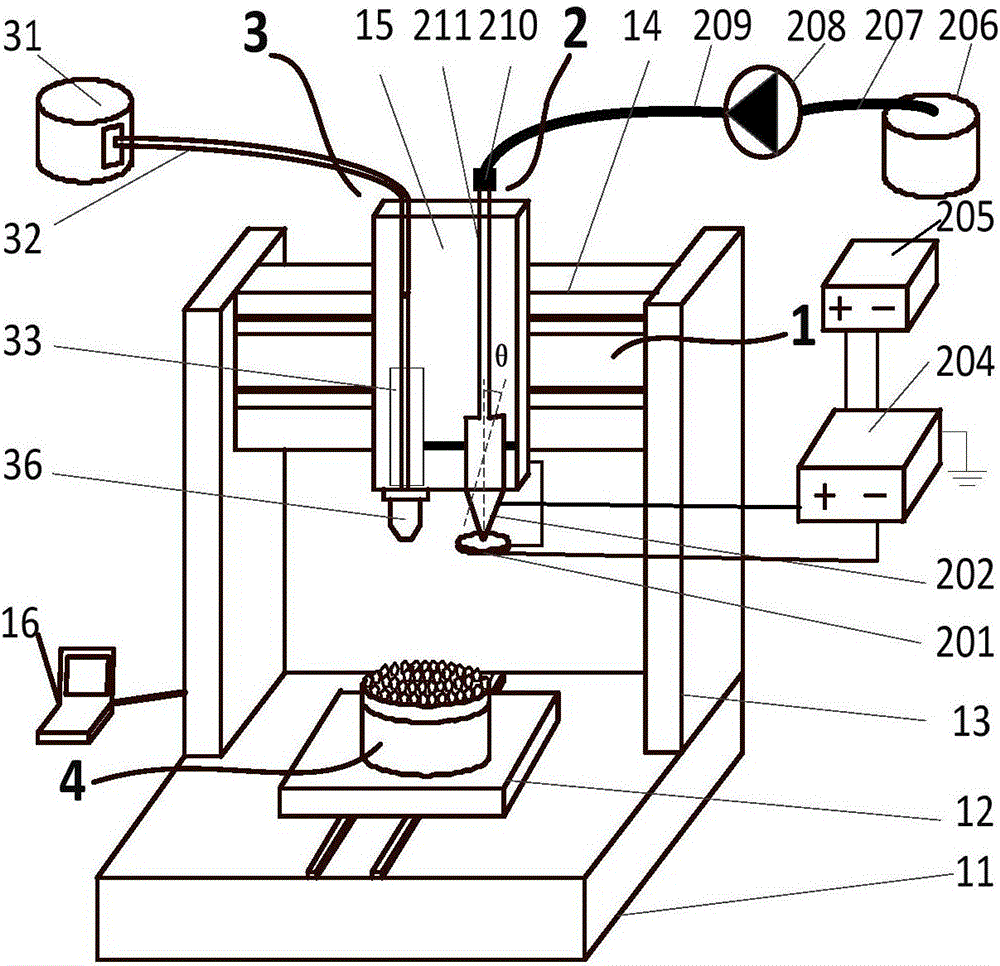

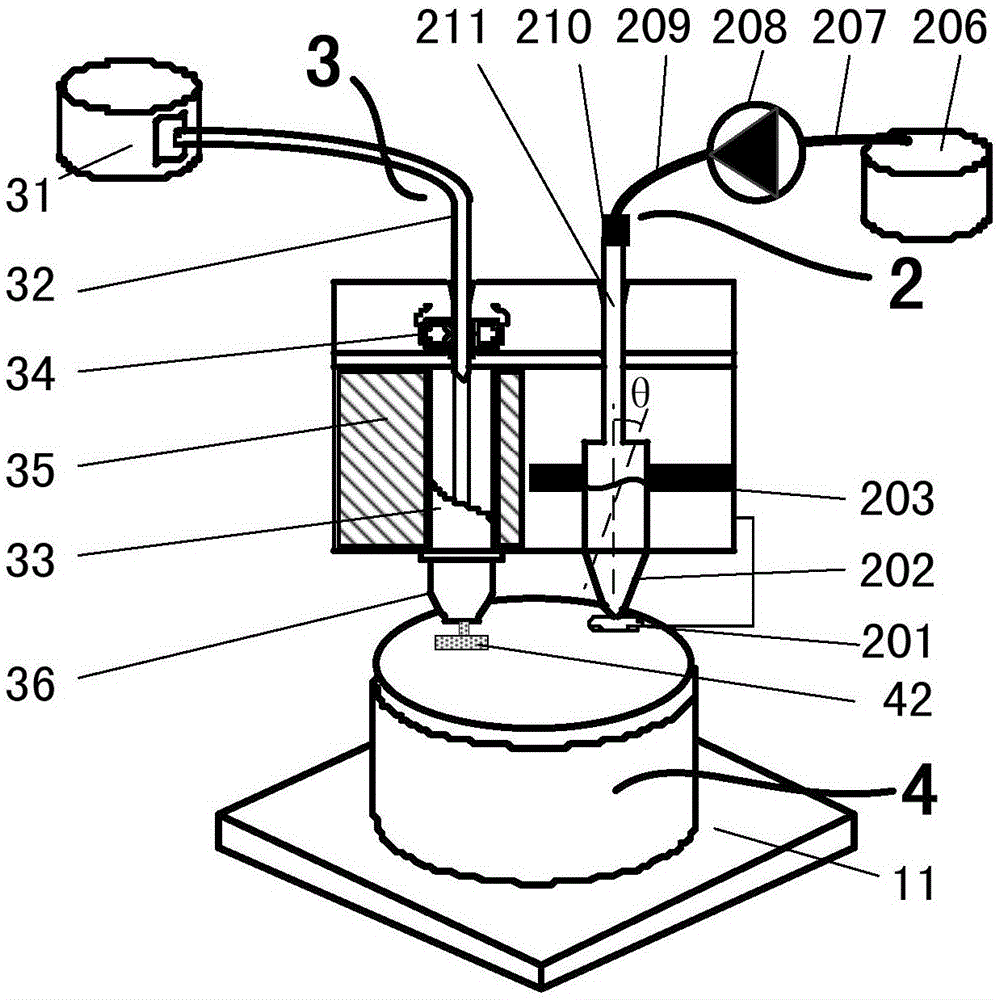

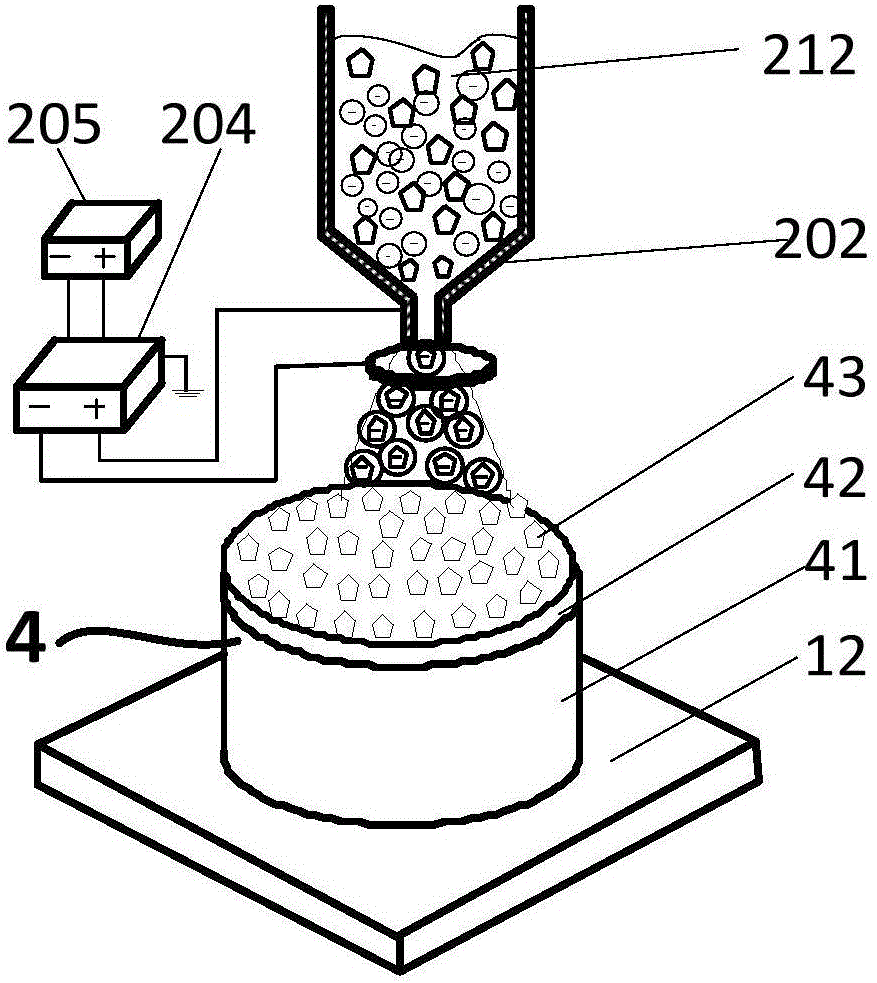

[0042] The preparation device and method of the diamond resin grinding wheel, the device is mainly composed of a motion control platform (1), an electrostatic atomization system (2), a grinding wheel printing system (3), and a printing grinding wheel (4). The motion control platform (1) includes a base (11), a base platform (12), a support frame (13), a translation platform (14), and a lifting platform (15) motion control device (16). The base platform (12), the translation platform (14), and the lifting platform (15) are controlled by the motion control device (15) to perform corresponding left and right, forward and backward translation, and up and down movements. The base (11) is connected with the base platform (12) and the support frame (13), and a grinding wheel base (31) is installed on the base platform (12). The support frame (13) is connected to the translation platform (14), the lifting platform (15) is connected to the translation platform (14), and the lifting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com