Method of manufacturing resin bonding grinding wheel

A technology of resin bonding and manufacturing method, which is applied in the direction of manufacturing tools, abrasives, metal processing equipment, etc., to achieve the effects of reducing the risk of cracks, small deviation of pores, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] 1. Manufacture of grinding wheel and measurement of physical properties

[0094] The physical properties of the resin-bonded grinding wheel produced by the first embodiment of the production method of the present invention (Example 1) and the method disclosed in WO 01 / 85394 (Comparative Example 1) were measured in the following procedures. The composition of the grinding wheel was adjusted so that the abrasive particle volume ratio = 15%, the binder volume ratio = 18%, and the pore volume ratio = 67%.

[0095] 1-1. Manufacture of grinding wheel (Example 1)

[0096] 1-1-1. Raw materials

[0097] Abrasive grain GC#2000 944g

[0098] Binder: Resole phenolic resin 420g

[0099] (manufactured by Asahi Organic Material Industry Co., Ltd., product number: HPR 830)

[0100] Curing agent: γ-butyrolactone 104g

[0101] Foaming agent (Dashi Chemical, product number: Uniform AZ 90) 43g

[0102] water 210g

[0103] 1-1-2. Grinding wheel manufacturing steps

[0104] Put binde...

Embodiment 2 and 3

[0177] 1. Manufacture of grinding wheel and measurement of physical properties

[0178] According to the second embodiment (Example 2) of the manufacturing method of the present invention and the resin bonded grinding wheel manufactured by the first embodiment (Example 3 (comparison with Example 2)) of the manufacturing method of the present invention, it is determined by the following steps Various properties. The composition of the grinding wheel was adjusted so that the abrasive grain volume ratio = 22%, the binder volume ratio = 24%, and the pore volume ratio = 54%.

[0179] 1-1. Manufacture of grinding wheel (Example 2)

[0180] 1-1-1. Raw materials

[0181] Abrasive GC#2000 1118g

[0182] Phenolic resin: resole type phenolic resin (non-volatile content 45%) 420g

[0183] (manufactured by Asahi Organic Material Industry Co., Ltd., product name: HPR830)

[0184] Curing accelerator: γ-butyrolactone 104g

[0185] Reinforcing agent: thermosetting resole phenolic resin 4...

Embodiment 2

[0215] In Example 2, compared with Example 3, the flexural strength was 70% or more higher, and the flexural modulus was 3 times or more higher. The high flexural modulus in Example 2 is estimated to be due to the higher uniformity of pores than in Example 3.

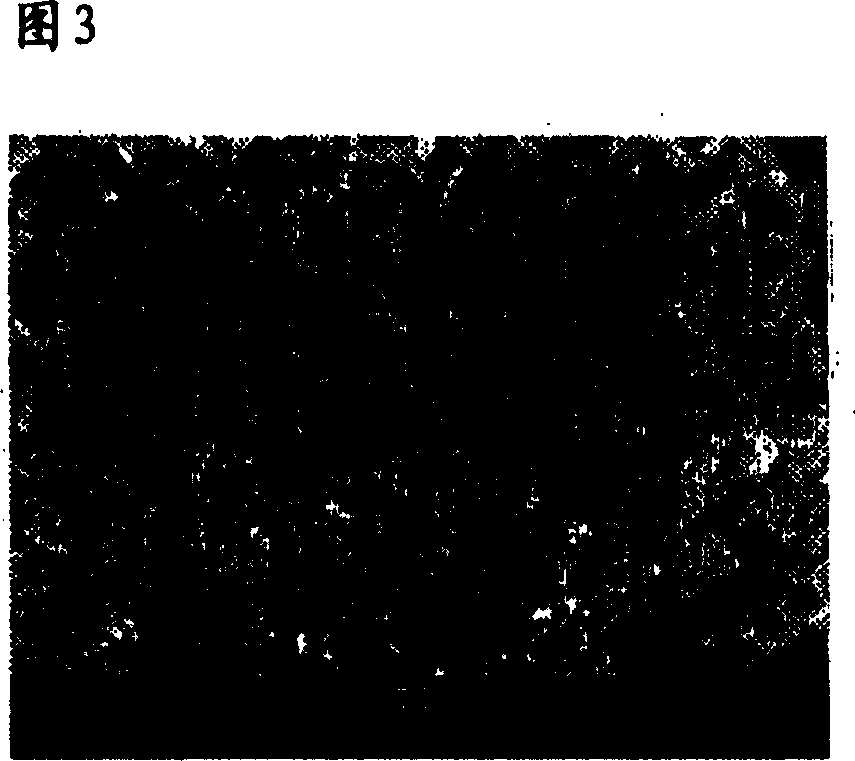

[0216] Comparing the structure of the grinding wheel, it can be seen that the pore size of Example 2 shown in Figure 3 is 10-100 μm, and the pores are evenly distributed, while the example 3 shown in Figure 4 has uneven distribution of the pores of the grinding wheel. In addition, it was observed that the abrasive grains were firmly held by the binder in Example 2, whereas the abrasive grains in Example 3 were free. This is judged to be because in Example 2, the strength of the resin was increased due to the action of the reinforcing agent, thereby firmly holding the abrasive grains. On the other hand, in Example 3, it was judged that the strength of the binder was weak, the holding force of the abrasive grains was ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com