Resin metal composite bonding agent and composite bonding agent diamond grinding wheel

A composite bond and diamond grinding wheel technology, which is applied in the field of diamond grinding wheels, can solve the problems that non-metal and non-ferrous metal materials cannot be processed, and achieve the effects of good self-sharpening, good temperature resistance and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

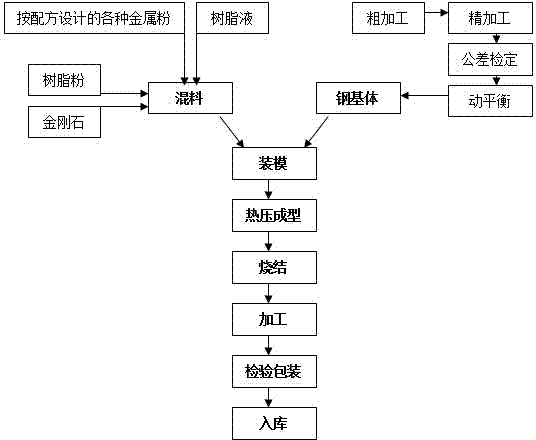

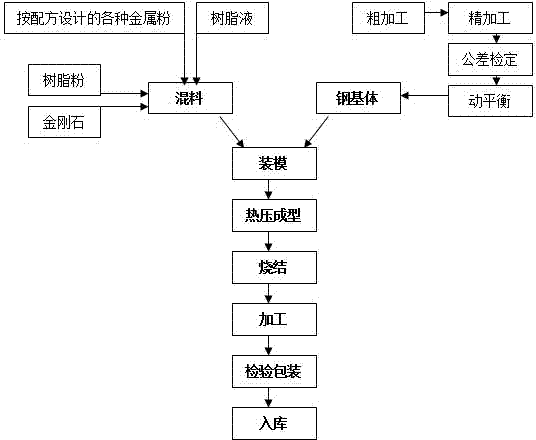

[0031] Embodiment one: see figure 1 Shown, prepare composite bond diamond grinding wheel, comprise the following steps:

[0032] (1) Mixing: The raw materials with the following weight ratio: polyimide resin powder 25%; copper powder 15%; tin powder 45%; zinc powder 7%; phosphorus powder 7%; Mix in the machine for 12 hours, and pass through a 320-mesh standard sieve to make a composite binder; then put the composite binder and diamond abrasive into the cylinder mixer in proportion to mix, and slowly add the resin solution after detecting uniformity under a microscope. Continue to mix for 1 to 2 hours, pass through a 60-mesh standard sieve after uniformity, obtain the grinding wheel mixture, and put it in a container for later use; wherein, the volume ratios of composite binder, diamond, and resin liquid are: 67%, 32%, and 1%; The diamond is a nickel-plated diamond with a particle size of 100 / 120, which is available in the market and whose quality meets the national standard; ...

Embodiment 2

[0038] Embodiment two: see figure 1 As shown, the composite bond diamond grinding wheel is prepared, and the technological process is the same as that of Example 1, specifically:

[0039] (1) Mixing: the following raw materials by weight: polyimide resin powder 28%; copper powder 18%; tin powder 41%; zinc powder 6%; phosphorus powder 6%; lead powder 1%; Mix in the machine for 12 hours, and pass through a 320-mesh standard sieve to make a composite binder; then put the composite binder and diamond abrasive into the cylinder mixer in proportion to mix, and slowly add the resin solution after detecting uniformity under a microscope. Continue mixing for 1 to 2 hours, pass through a 60-mesh standard sieve and put it into a container for later use to obtain a grinding wheel mixture; wherein, the volume ratios of the composite binder, diamond, and resin liquid are: 64%, 25%, and 1% respectively; The diamond is a nickel-plated diamond with a particle size of 140 / 170, which is availab...

Embodiment 3

[0046] see figure 1 As shown, the composite bond diamond grinding wheel is prepared, and the technological process is the same as that of Example 1, specifically:

[0047] (1) Mixing: the following raw materials by weight: polyimide resin powder 20%; copper powder 19%; tin powder 48%; zinc powder 5%; phosphorus powder 7%; lead powder 1%; Mix in the machine for 12 hours, and pass through a 320-mesh standard sieve to make a composite binder; then put the composite binder and diamond abrasive into the cylinder mixer in proportion to mix, and slowly add the resin solution after detecting uniformity under a microscope. Continue mixing for 1 to 2 hours, pass through a 60-mesh standard sieve and put it into a container for later use to obtain a grinding wheel mixture; wherein, the volume ratios of the composite binder, diamond, and resin liquid are: 64%, 25%, and 1% respectively; The diamond is a nickel-plated diamond with a particle size of 230 / 270, which is available in the market...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Curing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com