Detection method for resin bonding strength

A technology of strength detection and resin bonding, applied in measuring devices, instruments, mechanical devices, etc., can solve problems affecting the accuracy of bonding strength, cracking of resin layers, affecting the accuracy of resin bonding strength, etc., to improve the detection The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

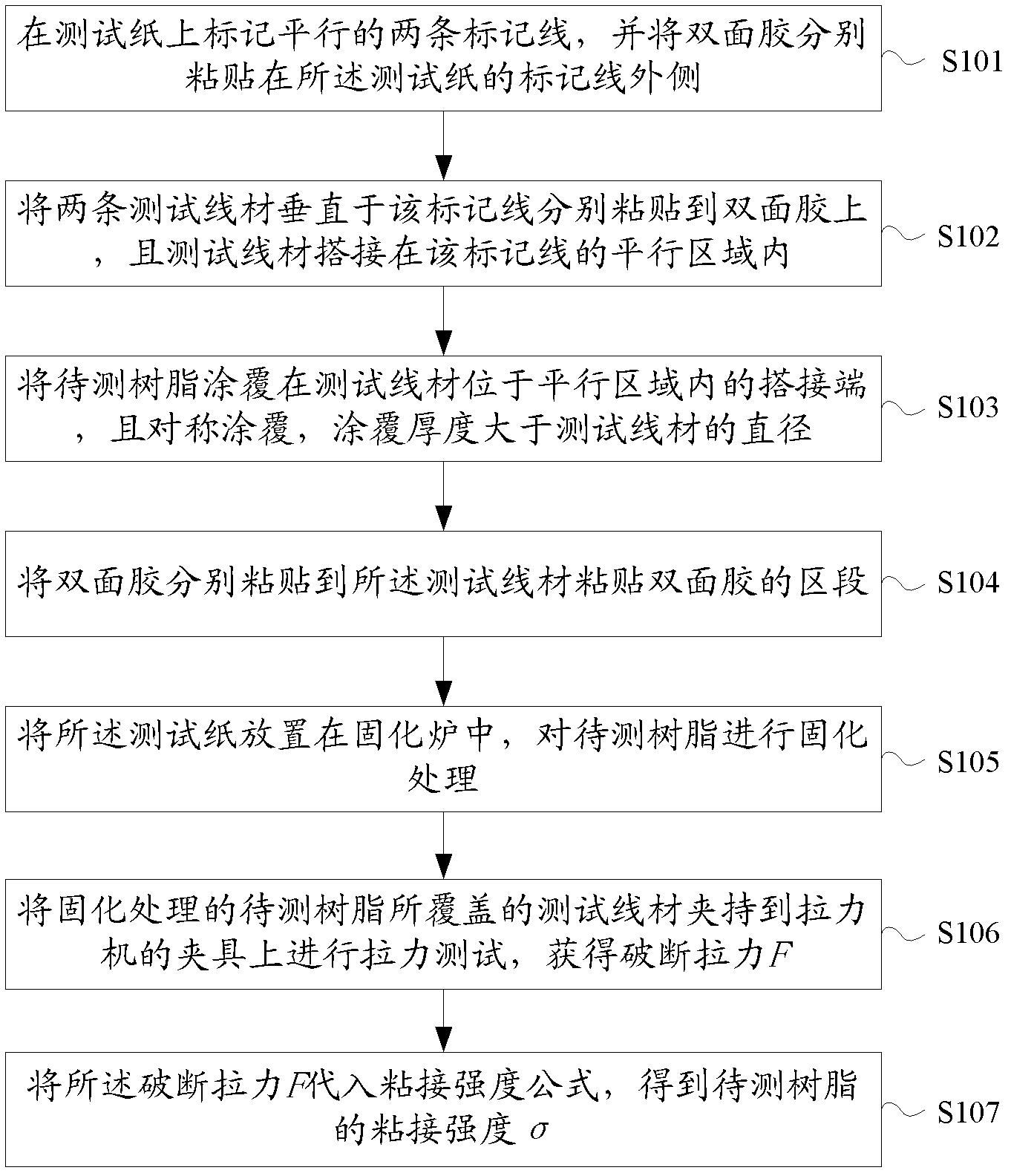

[0018] In order to realize the accurate detection of the bonding strength of the resin with brittle characteristics, an embodiment of the present invention provides a method for detecting the bonding strength of the resin, including:

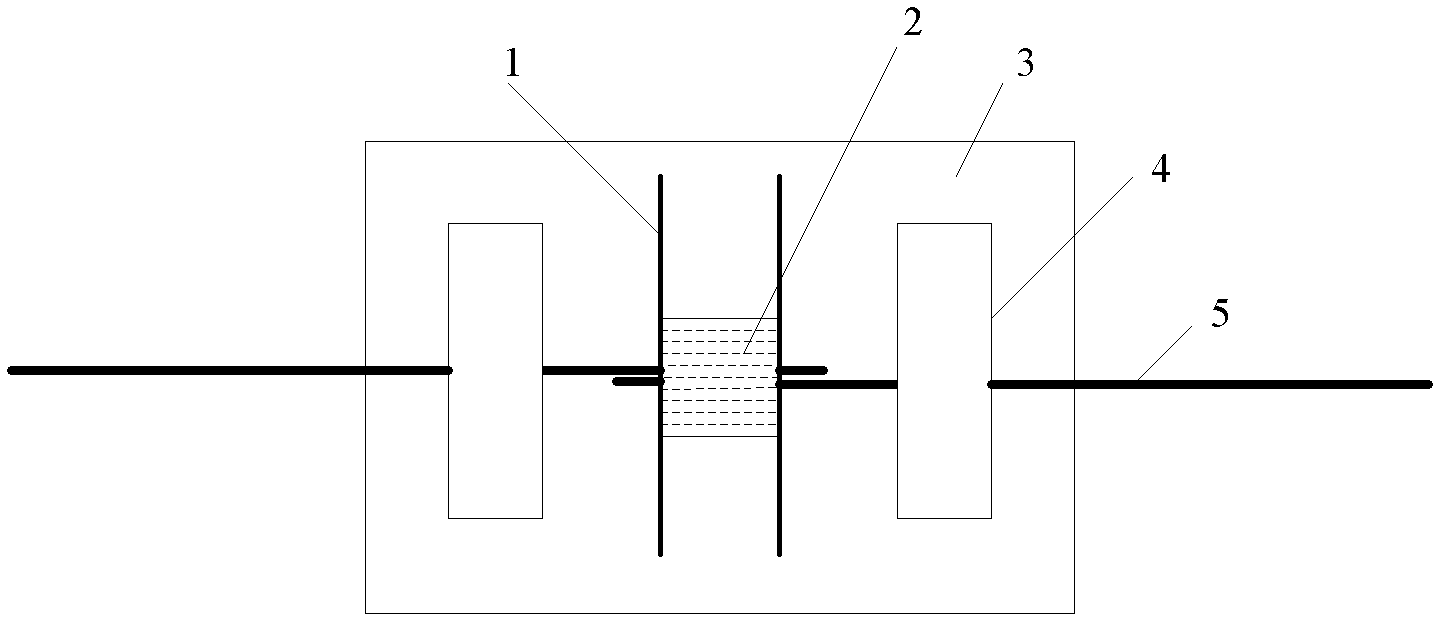

[0019] Mark two parallel marking lines on the test paper, and paste the double-sided tape on the outside of the marking lines of the test paper respectively;

[0020] Paste two test wires perpendicular to the marking line on the double-sided adhesive tape respectively, and the test wires overlap in the parallel area of the marking line;

[0021] Coating the resin to be tested on the overlapping joints of the test wires;

[0022] Fixing the section where the test wire is pasted with double-sided tape;

[0023] Curing the resin to be tested;

[0024] Clamp the test wire covered by the cured resin to be tested to the fixture of the tensile machine to perform a tensile test to obtain the breaking force F;

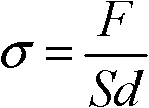

[0025] Substitute the breaking force ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com