Ceramic resin composite bonding agent grinding wheel and preparation method thereof

A technology of composite binder and ceramic resin, applied in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of easy heat generation and blockage, large thermal expansion, difficult to control processing accuracy, etc., and achieve grinding efficiency. High, good profile retention, high heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

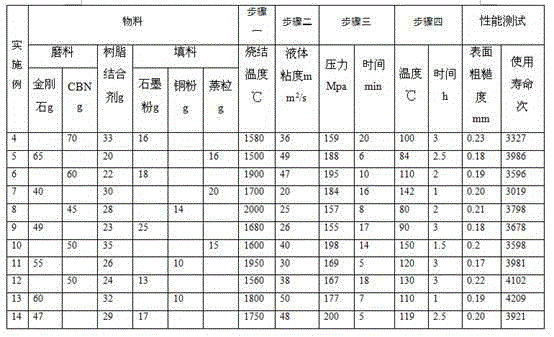

Examples

Embodiment 1

[0019] A ceramic resin composite bond grinding wheel and a preparation method thereof, comprising the steps of:

[0020] Step 1: Compress resin binder, abrasive material, filler, and pore-forming agent into molding, and sinter at a high temperature of 700-850°C to form a ceramic grinding wheel;

[0021] Step 2, dissolve the resin bond with acetone or alcohol, and add a curing agent to prepare a resin bond liquid with a viscosity of 20-50mm 2 / s;

[0022] Step 3, put the resin bond liquid prepared in step 2 into the rubber mold, put the vitrified grinding wheel into the rubber mold at the same time, seal the rubber mold mouth, put the sealed mold into the cold isostatic press at 150-200Mpa Take it out after pressing for 5-20min under the pressure;

[0023] Step 4, bake the resin bonded grinding wheel treated in Step 3 in an oven at 80-200 degrees for 1-3 hours.

[0024] The mass percentage of the vitrified bond is 20--35%, the mass percentage of the abrasive is 40-70%, the m...

Embodiment 2

[0030] A ceramic resin composite bond grinding wheel and a preparation method thereof, comprising the steps of:

[0031] Step 1: Compress resin binder, abrasive material, filler, and pore-forming agent into molding, and sinter at a high temperature of 700°C to form a ceramic grinding wheel;

[0032] Step 2, dissolve the resin bond with alcohol, and add a curing agent to prepare the resin bond liquid, the liquid viscosity is 50mm 2 / s;

[0033] Step 3, put the resin bond liquid prepared in step 2 into the rubber mold, put the vitrified grinding wheel into the rubber mold at the same time, seal the rubber mold mouth, put the sealed mold into the cold isostatic press at a pressure of 200Mpa Take it out after pressing down for 20 minutes;

[0034] Step 4, baking the resin bonded grinding wheel processed in Step 3 in an oven at 200 degrees for 3 hours.

[0035] The quality of the vitrified bond is 35 kg, 40 kg of abrasive, 10 kg of filler, 25 kg of pore-forming agent, and the pa...

Embodiment 3

[0043] A ceramic resin composite bond grinding wheel and a preparation method thereof, comprising the steps of:

[0044] Step 1: Compress resin binder, abrasive material, filler, and pore-forming agent into molding, and sinter at a high temperature of 750°C to form a ceramic grinding wheel;

[0045] Step 2, dissolve the resin bond with acetone or alcohol, and add a curing agent to prepare a resin bond liquid with a viscosity of 20mm 2 / s;

[0046] Step 3, put the resin bond liquid prepared in step 2 into the rubber mold, put the vitrified grinding wheel into the rubber mold at the same time, seal the rubber mold mouth, put the sealed mold into the cold isostatic press at a pressure of 150Mpa Take it out after pressing down for 15 minutes;

[0047] Step 4, bake the resin bonded grinding wheel treated in Step 3 in an oven at 150 degrees for 2 hours.

[0048] The vitrified bond is 20 kg, abrasive 60 kg, filler 15 kg, pore-forming agent 20 kg, and the particle size of the pore-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com