LED encapsulation structure and method

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as low production efficiency, unfavorable large-scale production, and adverse effects of phosphor powder, so as to improve reliability and improve light and color quality and luminous uniformity, the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

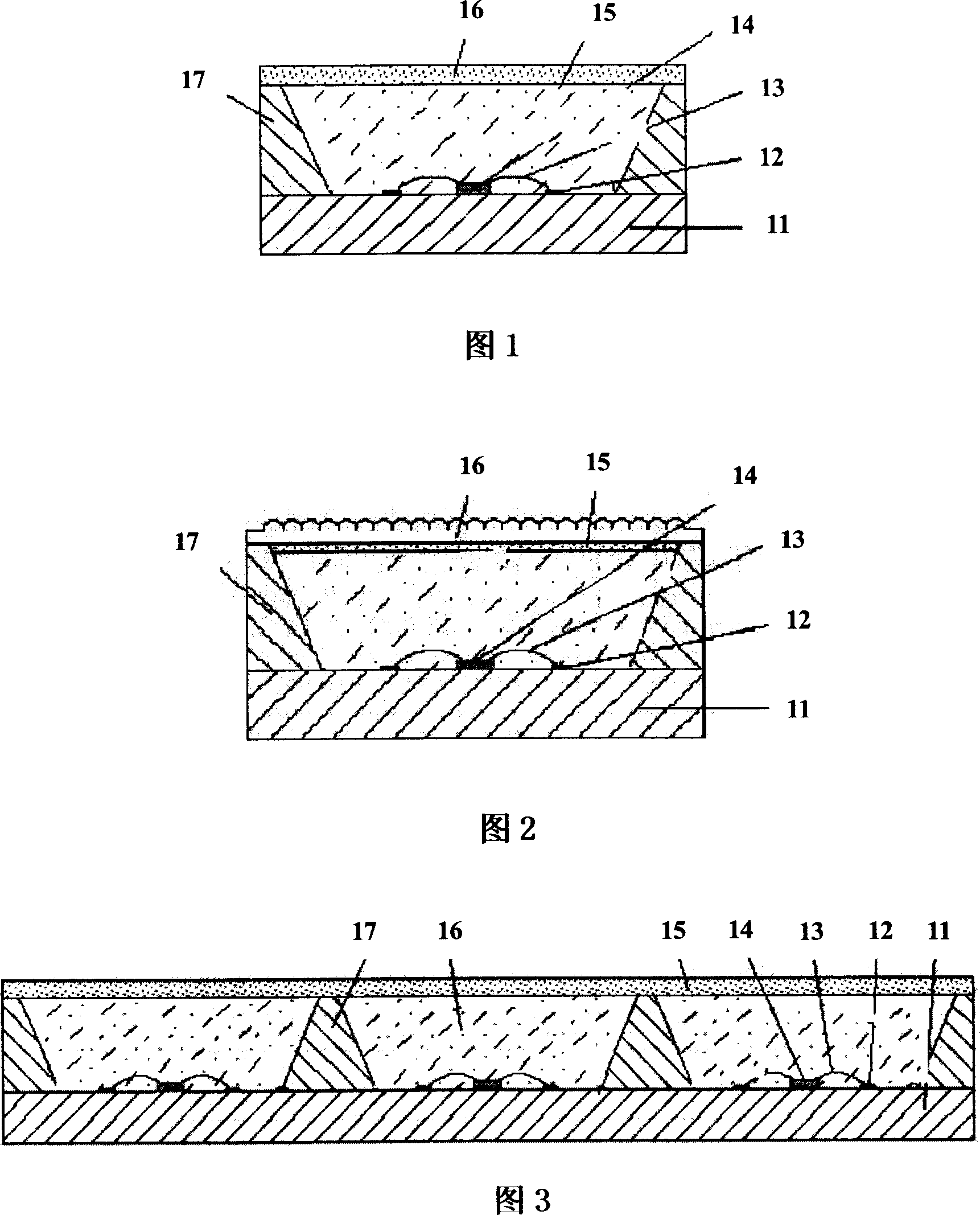

[0010] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0011] See Figure 1, the specific packaging process is as follows:

[0012] A. The GaN blue LED chip 14 is welded to the chip area of the copper-clad ceramic heat dissipation substrate 11 by low-temperature solder, and connected to the pad 12 by the metal lead 13;

[0013] B. Making a transparent body 15 on the Blu-ray chip 14 through a molding process of silica gel;

[0014] C. bonding the aluminum reflective cup 17 around the blue chip 14;

[0015] D. Add aluminum yttrium garnet (YAG) yellow fluorescent powder 18 into the glass-ceramic raw material, mix it evenly, sinter and form it, and then cut, grind and polish it to prepare the fluorescent powder-containing substrate 16;

[0016] E. Fix the phosphor-containing substrate 16 to the top of the reflective cup 17 by glue.

Embodiment 2

[0018] Embodiment 2 is the same as Embodiment 1, except that a microlens array is formed on the surface of the glass substrate 16 through a micromachining process, and the phosphor 18 is deposited on the substrate 16 by evaporation deposition or glue. Adhesive surface, finally the substrate 16 is fixed to the top of the reflective cup 17 by glue, see FIG. 2 .

Embodiment 3

[0020] Embodiment 3 is the same as Embodiment 1, except that the single-color light-emitting chips 14 are in an array structure. The chip 14 is welded to the chip area of the heat dissipation substrate 11 to form a chip array, and is connected to the pad 12 through the metal lead 13, and the transparent body 15 is formed on the chip array 14 through a glue injection molding process, and then the reflective cup array 17 is fixed on the on the heat dissipation substrate 11 , corresponding to the chip 14 and the transparent body 15 , and finally the phosphor-containing substrate 16 is fixed on the top of the reflective cup array 17 . See Figure 3.

[0021] In each of the above embodiments, the surface of the substrate can also be a regular rough surface, and the light-emitting chip can also be a purple light chip or an ultraviolet light chip, and the corresponding fluorescent powder is RGB (red, green, blue) three-color fluorescent Powder; welding and anodic bonding can also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com