Paper-plastic composite film and production process thereof

A technology of paper-plastic composite and production process, which is applied in the direction of special paper, synthetic resin layered products, paper/cardboard layered products, etc. It can solve the problem that the shelf life and pressure resistance of packaging composite films cannot meet the requirements and affect the contents. Hygiene and safety, low composite film fastness and other issues, to achieve excellent strength and stiffness, low price, and good appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

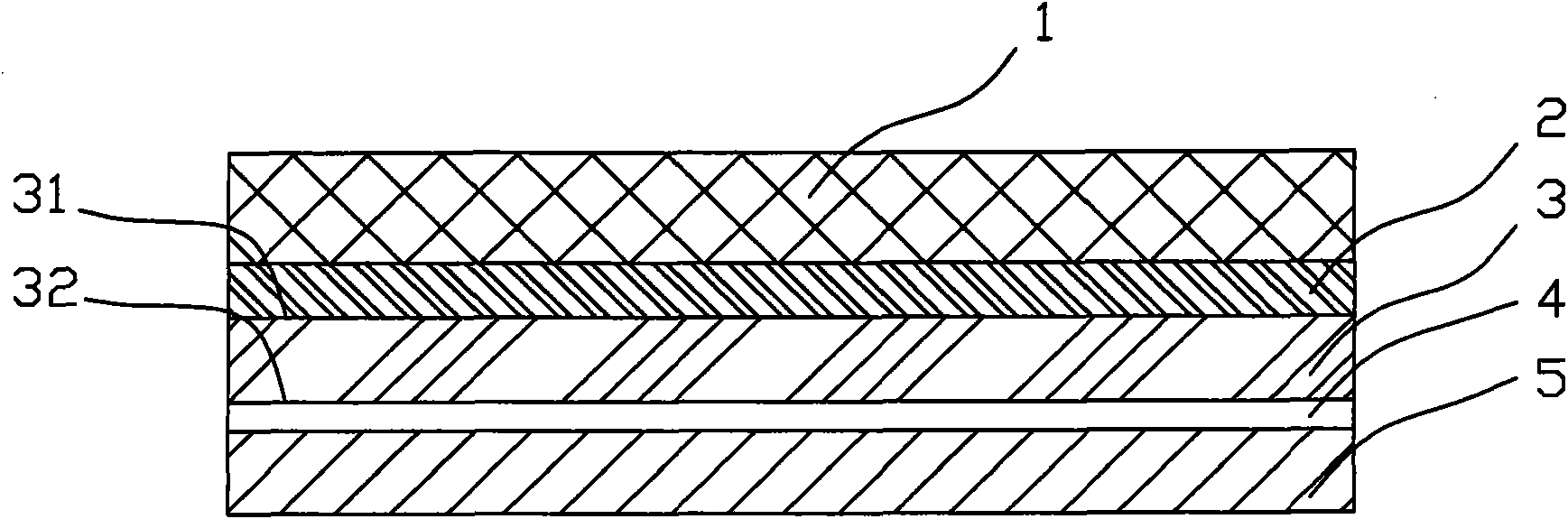

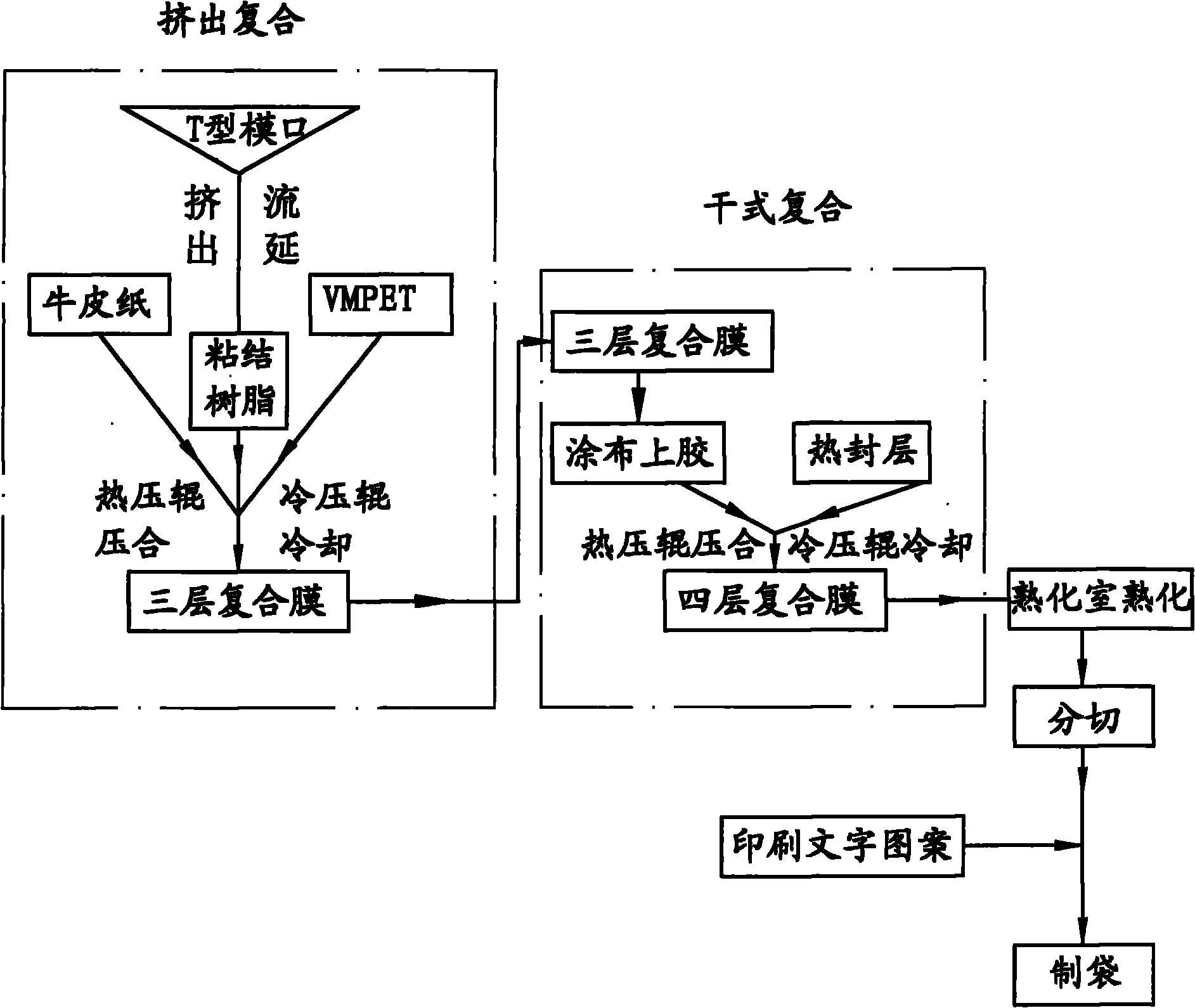

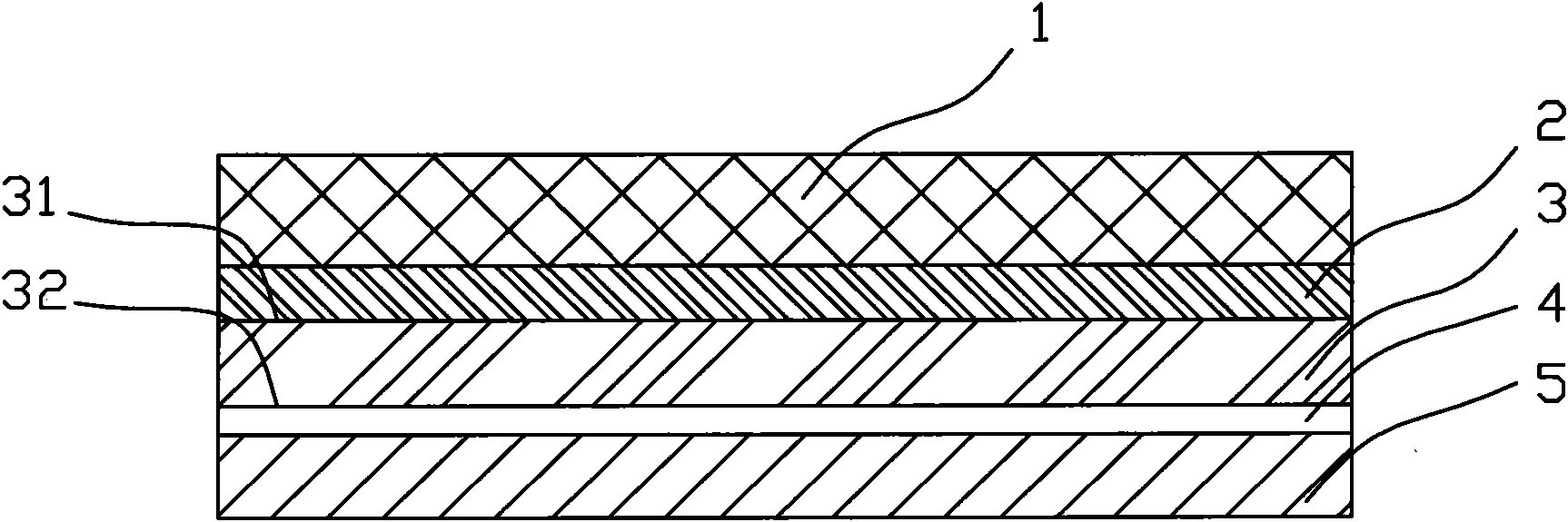

[0022] Extrusion compounding: kraft paper 1 and vacuum aluminized polyethylene terephthalate film 3 are synchronously entered into the T-shaped extrusion casting die, and at the same time, the polyethylene resin is directly melted and extruded from the T-shaped casting die. The resin adhesive layer 2 is formed between the kraft paper 1 and the aluminum-coated surface 31 of the vacuum aluminum-coated polyethylene terephthalate film 3, pressed by a hot pressing roll and cooled by a cooling roll, and wound to form a three-layer composite membrane;

[0023] Dry compounding: the polyethylene terephthalate surface 32 of the three-layer composite film is coated with a polyester polyurethane adhesive, and the solvent is dried in an oven to form an adhesive layer 4 and then bonded with polyethylene The film is laminated by a hot composite pressure roller and cooled by a cooling roller to form a heat-sealing layer 5, and finally wound to form a four-layer composite film;

[0024] The a...

Embodiment 2

[0028] Extrusion compounding: kraft paper 1 and vacuum aluminized polyethylene terephthalate film 3 are synchronously entered into the T-shaped extrusion casting die, and at the same time, the polypropylene resin is directly melted and extruded from the T-shaped casting die. The resin adhesive layer 2 is formed between the kraft paper 1 and the aluminum-coated surface 31 of the vacuum aluminum-coated polyethylene terephthalate film 3, pressed by a hot pressing roll and cooled by a cooling roll, and wound to form a three-layer composite membrane;

[0029] Dry compounding: the polyethylene terephthalate surface 32 of the three-layer composite film is coated with a polyester polyurethane adhesive, and the solvent is dried in an oven to form an adhesive layer 4 and then combined with polypropylene Laminated by hot composite pressing rollers and cooled by cooling rollers to form a heat-seal layer 5, and finally wound to form a four-layer composite film;

[0030] The above-mentione...

Embodiment 3

[0034] Extrusion compounding: Put kraft paper 1 and vacuum aluminized polyethylene terephthalate film 3 into the T-shaped extrusion casting die simultaneously, and melt and extrude ethylene-vinyl acetate copolymer directly from the T-shaped casting die The material is cast between the kraft paper 1 and the aluminum-coated surface 31 of the vacuum aluminized polyethylene terephthalate film 3 to form a resin bonding layer 2, which is pressed by a hot pressing roll and cooled by a cooling roll, and then rolled to form Three-layer composite film;

[0035] Dry compounding: the polyethylene terephthalate surface 32 of the three-layer composite film is coated with a polyester polyurethane adhesive, and the solvent is dried in an oven to form an adhesive layer 4 and then bonded with polyethylene The film is laminated by a hot composite pressure roller and cooled by a cooling roller to form a heat-seal layer 5, and finally wound to form a four-layer composite film;

[0036] The above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com