Nano technology modified ultraviolet solidified woodware paint

A wood coating and nanotechnology technology, applied in the field of UV-curing wood coatings, can solve the problems of poor wear resistance, poor anti-static performance, easy aging, etc., and achieve improved wear resistance and surface hardness, good toughness and resistance. Good crack resistance and anti-static properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0020] The coating described in Example 4 is applied on the decorative wood surface layer by roller coating, flow coating, spray coating, or dip coating, and the resulting coating film has good abrasion resistance.

Embodiment 5

[0021] The coating described in embodiment 5 is a white paint film with good hiding power, which is used to produce white UV cured woodware.

[0022] The main production method of the present invention is to pre-disperse specially modified nano-materials and appropriate monomers, then add other materials and pre-dispersed nano-materials into the reactor in sequence, and slowly heat up, adjusting the temperature to 55- 65°C / 1hr, pump into the reactor, add photosensitive diluent and mix at 50~60°C / 2hr, then add photosensitive curing synergist and other additives.

[0023] Nanotechnology is a hot research topic in the world in the 21st century. Using nanotechnology to modify UV-cured wood coatings will not only upgrade UV coating products, but also promote the expansion of UV coatings to high-tech fields (such as aerospace, electronic materials) and other fields.

[0024]

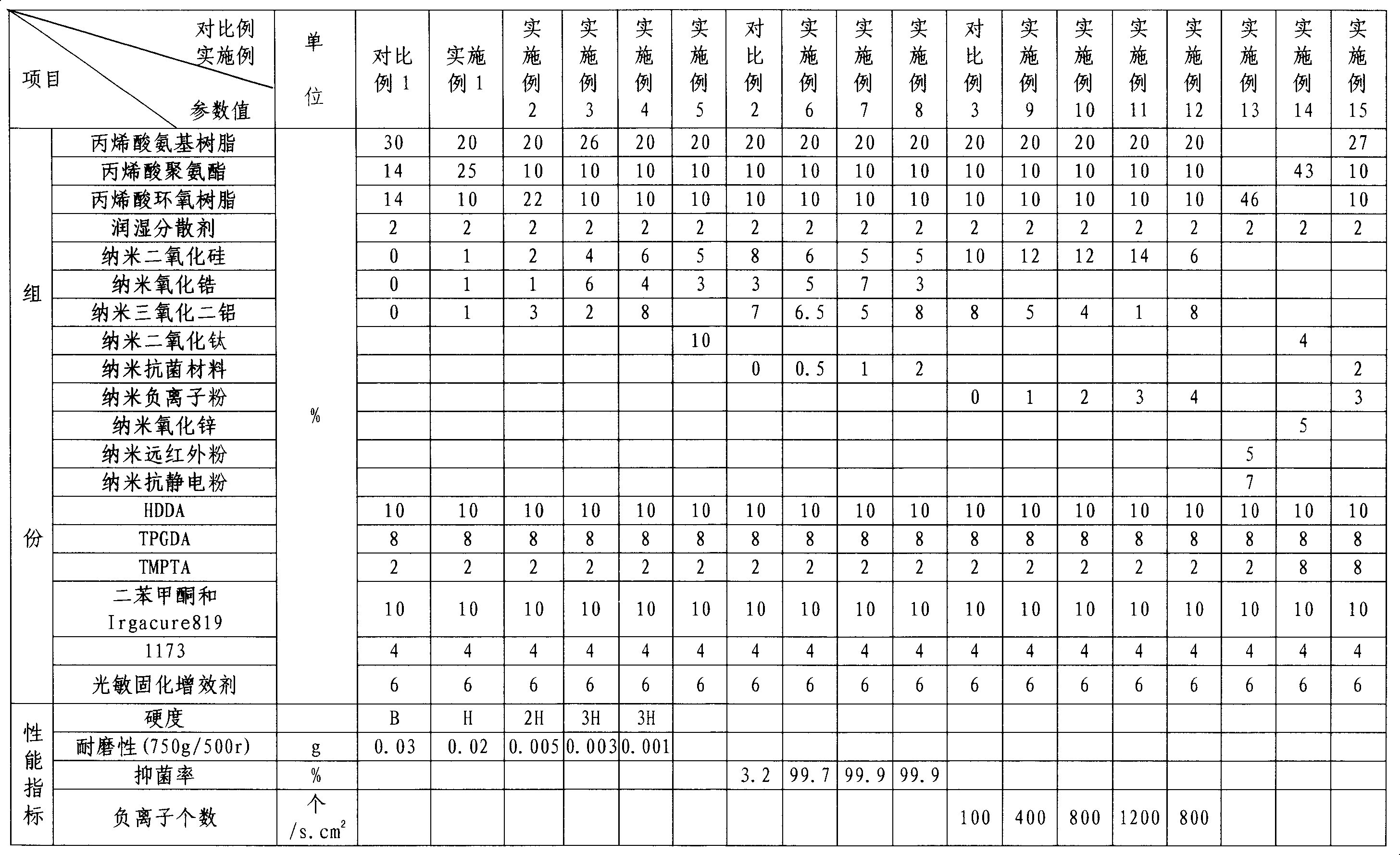

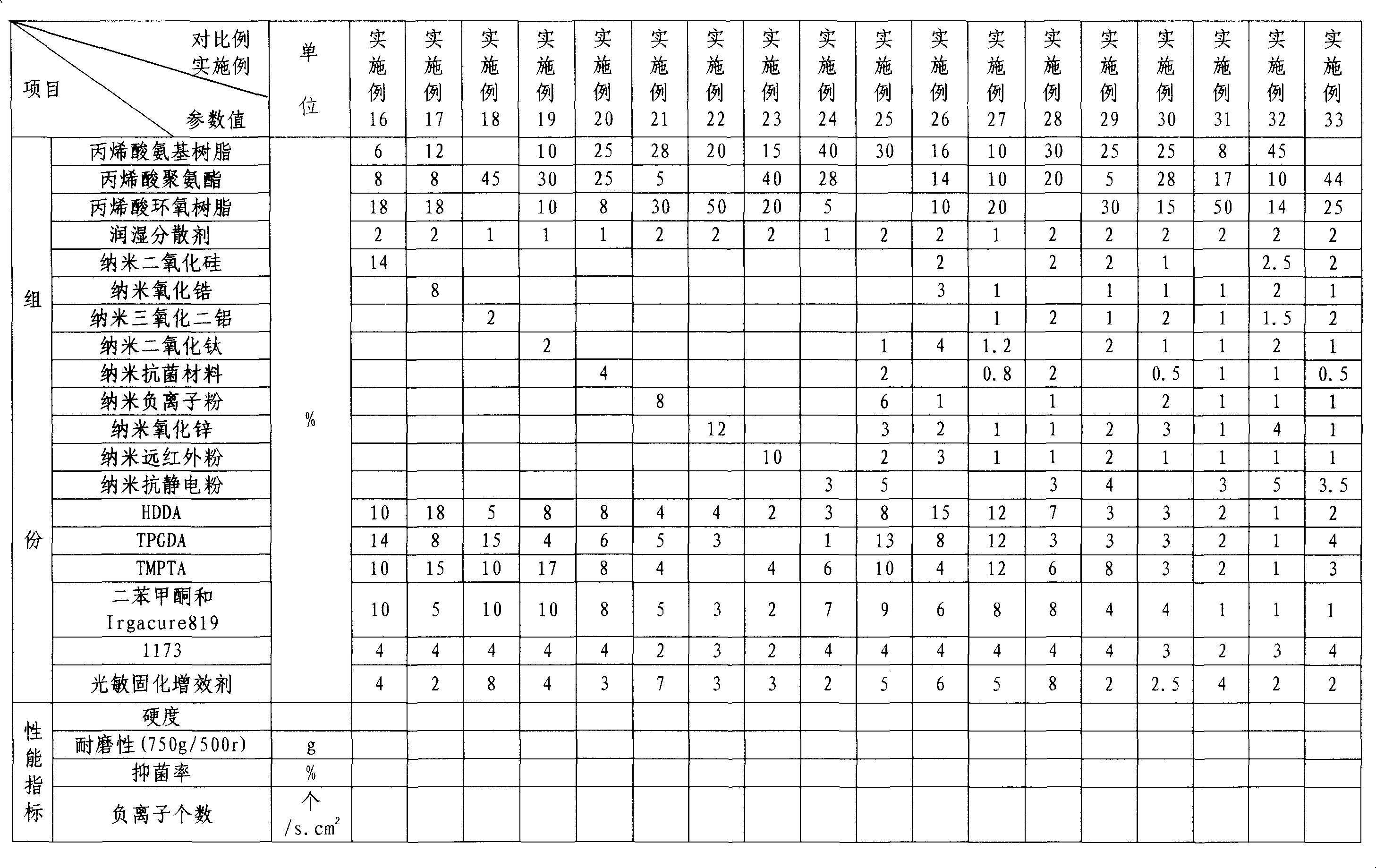

[0025] Table 1

[0026]

[0027] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com