Water-based environment-friendly low-temperature matte coating

A low-temperature, matte technology, applied in epoxy resin coatings, electrophoretic coatings, coatings, etc., can solve the problem of not meeting the green needs of energy saving and environmental protection, the reduction of coating leveling and mechanical properties, the reduction of extinction efficiency and the coating Membrane stability and other issues, to achieve the effect of good bath circulation stability, excellent salt spray resistance, and excellent matte effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

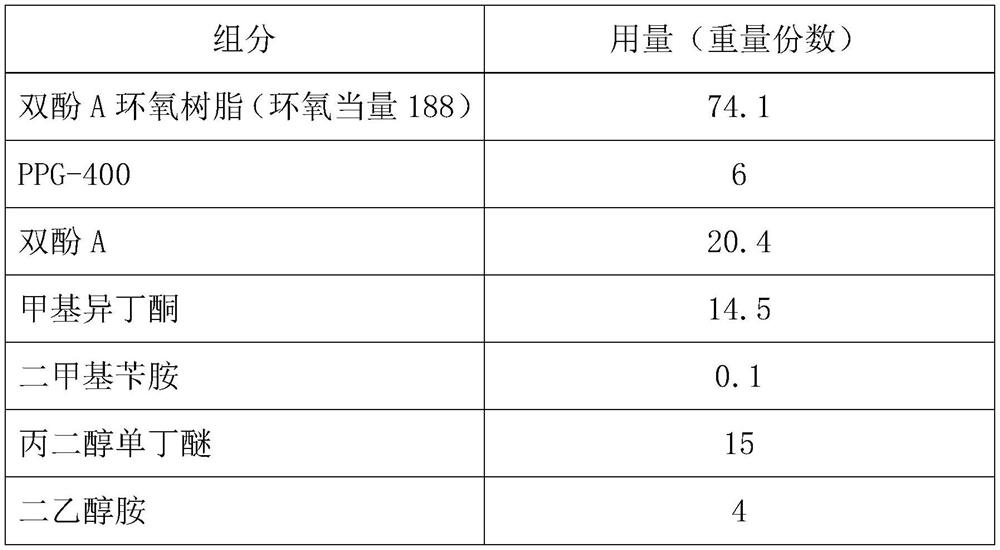

[0027] The preparation of embodiment 1 cationic modified resin

[0028]

[0029]

[0030] In a flask equipped with a thermometer, a stirrer and a reflux condenser, add bisphenol A epoxy resin with an epoxy equivalent of 188, PPG-400, bisphenol A and methyl isobutyl ketone according to the formula, and heat up to 100°C , add dimethylbenzylamine, continue to heat up to 125°C and stir for 1.5 hours until the epoxy equivalent is 800-900, add propylene glycol monobutyl ether, cool down to 75°C, add diethanolamine and react at 80°C for 1H, then Then add ketimine, raise the temperature to 100° C. and keep it for 2 hours, then lower the temperature to 70° C. to obtain a cation-modified resin.

[0031] The matrix epoxy resin is modified by PPG-400, which improves the reactivity with the crosslinking agent and impact strength, which can improve the flexibility and heat resistance of the coating film; after amination, it forms a cationic modified resin.

Embodiment 2

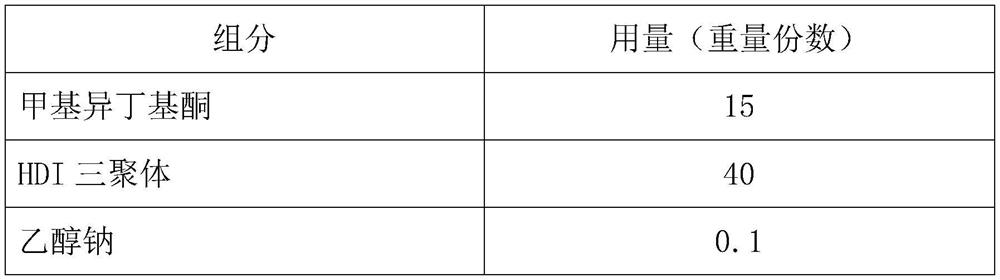

[0032] Embodiment 2 prepares the first curing agent

[0033] components Dosage (parts by weight) methyl isobutyl ketone 25 HDI trimer 40 Methyl ethyl ketone oxime 15 3,5 Dimethylpyrazole 5 Ethylene glycol ether 5

[0034] Add methyl isobutyl ketone and 3,5 dimethylpyrazole into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, dissolve and heat up to 75°C, add HDI trimer dropwise, for 1 hour After dropping, continue to drop the mixture of ethylene glycol ether and methyl ethyl ketone oxime. After the dropwise addition, keep warm at 75°C for 2 hours, test NCO<0.5, cool down to below 45°C and discharge to obtain the first curing agent.

Embodiment 3

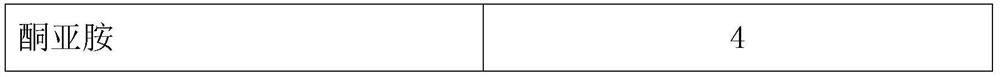

[0035] Embodiment 3 prepares the second curing agent

[0036]

[0037]

[0038] Add methyl isobutyl ketone, sodium ethoxide, and HDI trimer into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen, dissolve and heat up to 70°C, add PPG-400, keep warm for 1 hour, and then Continue to add the mixture of diethyl malonate and ethyl acetoacetate dropwise. After the dropwise addition, keep the temperature at 75°C for 2 hours, test NCO<0.5, cool down to below 45°C and discharge to obtain the second curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com